The preparation method of the material of the transparent soft rubber pillow body

A soft rubber and pillow technology, applied to pillows and other directions, can solve the problems of poor air permeability of transparent pillows, and achieve the effects of good anti-aging performance, easy drying and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

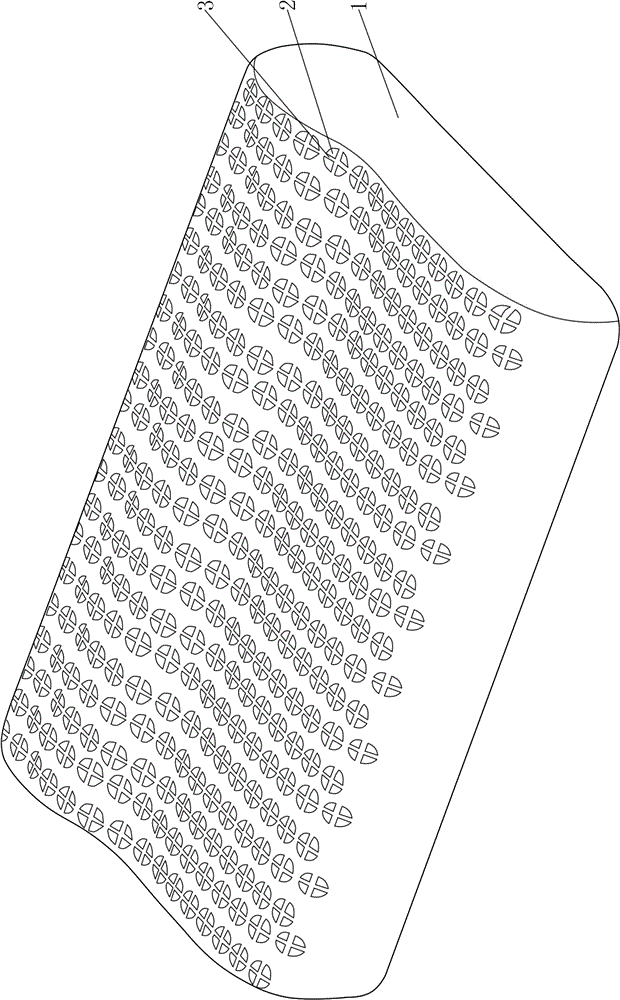

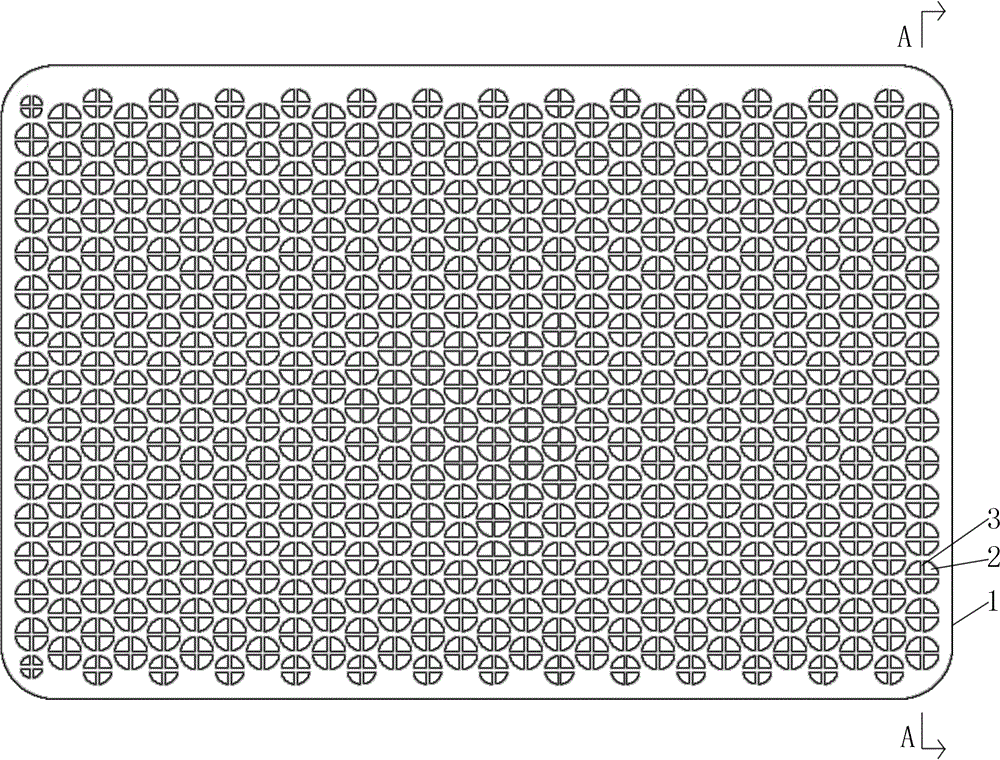

[0030] Such as Figure 1-3 As shown, the transparent soft rubber pillow in this embodiment includes a soft rubber pillow body 1, and a plurality of ventilation channels 2 are opened on the top surface of the soft rubber pillow body 1, and these ventilation channels 2 are arranged along the soft rubber pillow body 1. The cross section of the pillow is evenly distributed, and the air passage 2 is covered with the top surface of the soft rubber pillow body 1.

[0031] The top opening of the ventilation channel 2 is located on the top surface of the soft rubber pillow body 1, and the top opening of the ventilation channel 2 is provided with a shaping bracket 3, and the shaping bracket 3 is integrally made with the soft rubber pillow body 1. In this way, it can effectively prevent the opening at the top of the ventilation channel 2 from being deformed and closed under pressure, causing the ventilation channel 2 to lose its function of ventilation.

[0032] In a preferred solution,...

Embodiment 2

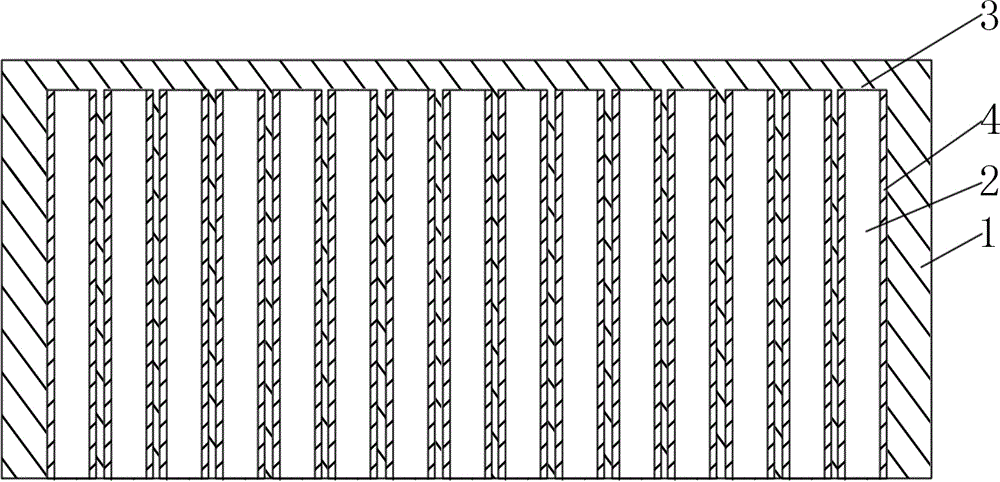

[0043] Such as Figure 4 , 5 Shown, the difference between the transparent soft rubber pillow in the present embodiment and embodiment 1 is:

[0044] The shaping bracket 3 extends from the top opening of the ventilation channel 2 to the bottom opening of the ventilation channel 2 . The advantage of this design is that the strength of the ventilation channel 2 is better, but the disadvantage is that more materials are consumed, the weight is heavier, and the air permeability is reduced.

[0045] The shape of the shaping bracket 3 is "1".

[0046] The volatilizable auxiliary drug element is a volatilizable auxiliary drug block installed on the inner side wall of the ventilation channel 2 .

[0047] In order to make the user more comfortable when using, a pillowcase is covered on the outside of the soft rubber pillow body 1, which can make the user feel more comfortable and prevent the soft rubber pillow body 1 from being soiled. If the pillowcase is dirty, it can be covered ...

Embodiment 3

[0054] The difference between the transparent soft rubber pillow in the present embodiment and embodiment 1 is:

[0055] The ventilation channel 2 is only distributed in the middle of the top surface of the soft rubber pillow body 1, and the distance between the edge of the top surface and any one of the ventilation channels 2 is greater than 1 cm.

[0056] There is no shaped bracket 3 at the top opening of the ventilation channel 2 .

[0057] There is no volatilizable auxiliary drug device or volatilizable auxiliary drug element in the ventilation channel 2 . But the user can spray the liquid medicine as needed.

[0058] Prepare the soft rubber pillow body 1 material according to the following procedures in sequence:

[0059] Step 1: Put 1000 grams of powdered melt-processing thermoplastic rubber into a container and knead until the temperature of the melt-processing thermoplastic rubber is 35 degrees;

[0060] Step 2: Add 3500 grams of No. 6 white oil to the melt-processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com