Chenille antiskid floor mat

A technology of chenille and chenille yarn, applied in the field of chenille anti-slip mats, can solve the problems of low hair fastness of chenille mats, high cost of manpower and material resources, easy wrinkling, etc. The assembly process is simple, the product quality is improved, and the anti-skid performance is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

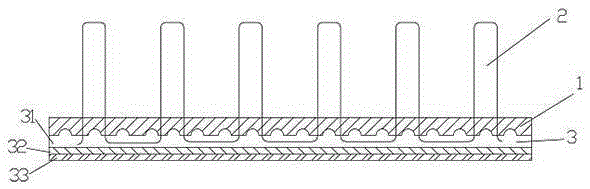

[0014] Such as figure 1 As shown, the chenille anti-slip floor mat provided in this embodiment includes a base cloth 1 on which chenille yarns 2 are interspersed, and an anti-slip layer 3 is coated on the back of the base cloth 1 .

[0015] The anti-slip layer 3 is composed of a massage layer 31 , a buffer layer 32 and a hot melt adhesive layer 33 from top to bottom in sequence, and the massage layer 32 is provided with circular bumps 34 .

[0016] The massage layer 31 is made of rubber elastic material. The buffer layer 32 is made of PU material or sponge. The base cloth 1 is a non-woven fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com