Metal film filter used in dye intermediate production

A technology for metal membrane filters and dye intermediates, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of affecting filtration accuracy, short cycle of filter bag reuse, and easy aging of seals, etc. Achieve the effect of improving the degree of automation, facilitating clean production, and reducing the number of cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail now in conjunction with accompanying drawing

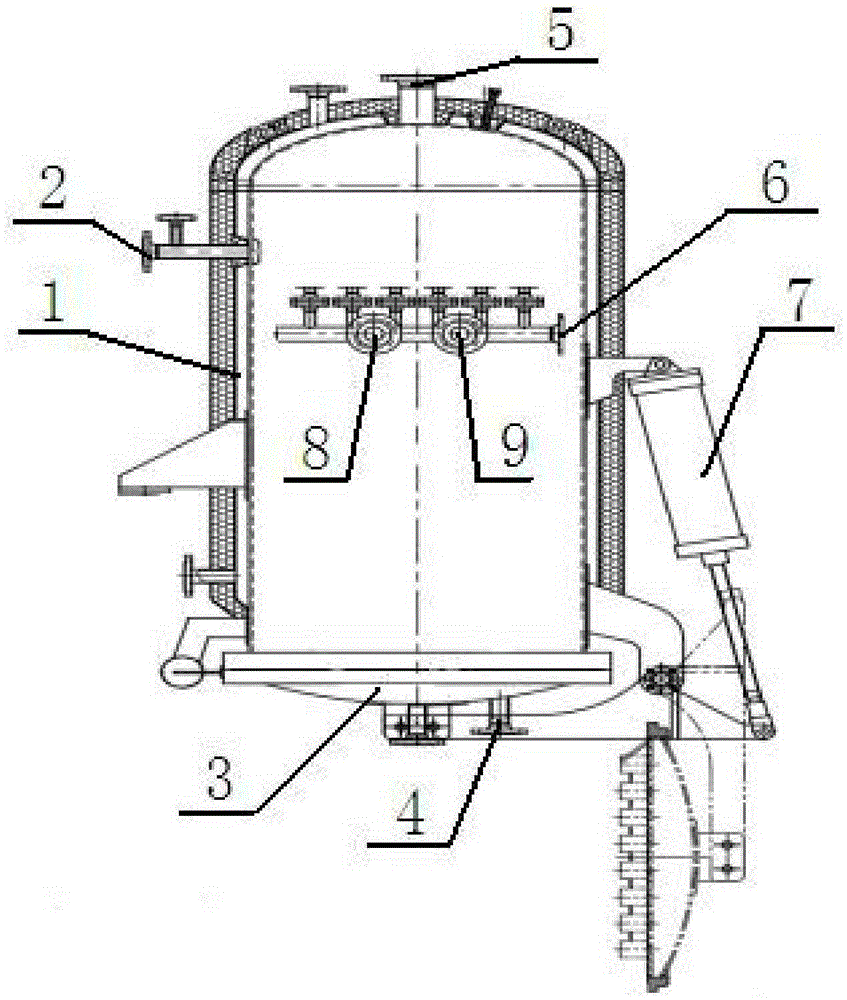

[0015] like figure 1 Shown, a kind of metal membrane filter that is used for the production of dyestuff intermediate comprises tank body 1 and sealing cover 3, and described sealing cover 3 is positioned at the bottom of tank body 1, and sealing cover 3 is connected with tank by connector and cylinder 7 The tank body 1 is connected, the upper part of the tank body 1 is provided with a feed inlet 2, the top of the tank body 1 is provided with a safety valve 5, and the tank body 1 is also provided with a discharge port 6, a blowback inlet 8 and a cleaning port 9. A sewage outlet 4 is provided at the bottom of the tank body 1 .

[0016] Specifically, the feed port 2 is located on the side wall of the tank body 1 .

[0017] Specifically, the sewage outlet 4 is located on the sealing cover 3 .

[0018] The feed liquid enters the filter from the feed port 2 through the transfer pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com