Cobalt-loaded lanthanum, manganese, calcium and titanium ore type nitric oxide oxidation catalyst and preparation method

An oxidation catalyst, perovskite-type technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as high price, achieve low cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

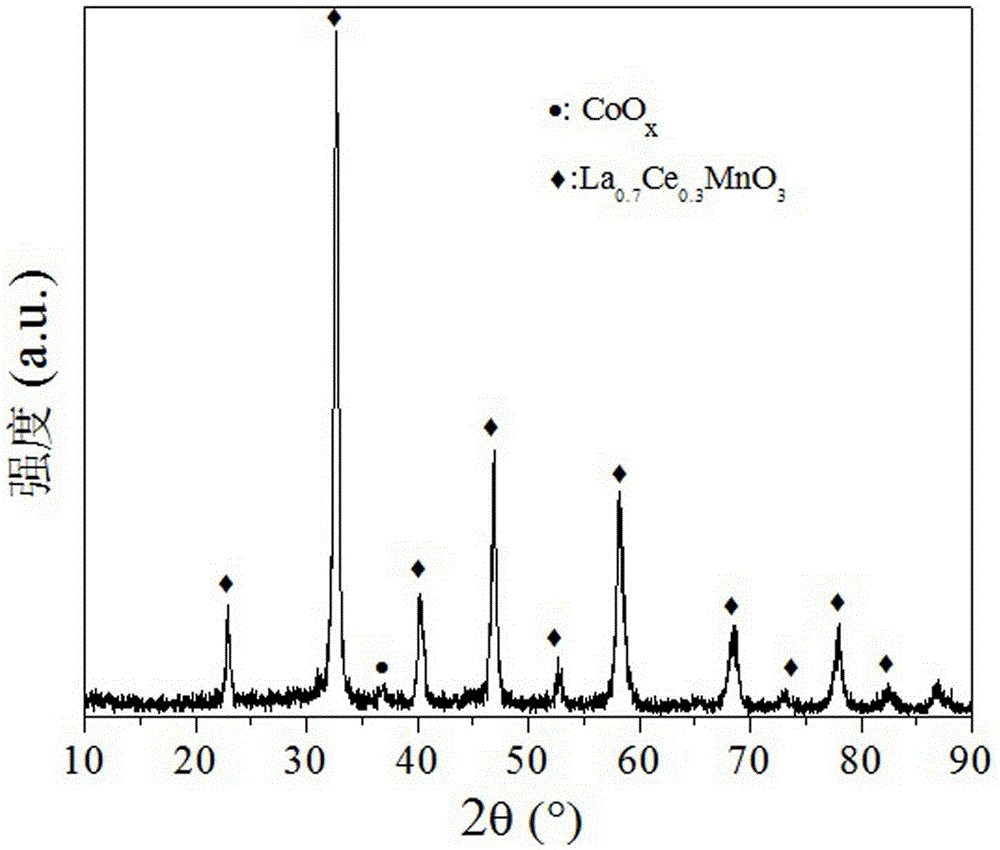

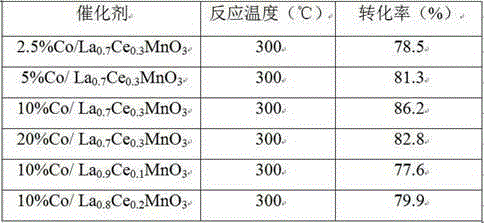

[0019] Put 2.27g of lanthanum nitrate, 1.30g of cerium nitrate, and 3.57g of 50wt% manganese nitrate into deionized water, fully dissolve and heat up to 80°C, add 4.62g of citric acid while stirring, and continue stirring until the water evaporates to produce a viscous Colloid, put the obtained colloid into an oven at 110°C to dry for 12 hours, take it out and grind it finely, and bake it at 700°C for 5 hours to obtain La 0.7 Ce 0.3 MnO 3 black powder. Weigh 0.247 g of cobalt nitrate and dissolve it in 1.50 ml of deionized water, then weigh 0.500 g of black powder and put it into the cobalt solution, let it stand for 10 hours, put it in an oven at 70°C for 12 hours, and then bake it at 500°C for 5 hours. According to X-ray powder diffraction, the powder is 10%Co / La 0.7 Ce 0.3 MnO 3 Catalysts such as figure 1 shown.

Embodiment 2

[0021] Compared with Example 1, the difference is that the quality of cobalt nitrate is 0.123 grams, and the amount of other materials and operating conditions are the same as in Example 1 to obtain 5%Co / La 0.7 Ce 0.3 MnO 3 catalyst.

Embodiment 3

[0023] Compared with Example 1, the difference is that the quality of cobalt nitrate is 0.494 grams, and other material consumption and operating conditions are the same as in Example 1 to obtain 2.5%Co / La 0.7 Ce 0.3 MnO 3 catalyst.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap