Telescopic device for absorbing collision energy of railway vehicle

A rail vehicle, collision energy absorption technology, applied in the direction of railway vehicle wheel guards/buffers, buffer cars, transportation and packaging, etc., can solve the problems of residual deformation and inability to make full use of the deformation stroke, so as to improve the energy absorption capacity, Protect the safety of vehicles and passengers and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be fully described below in conjunction with the drawings in the embodiments of the present invention. The described embodiments are some, but not all, embodiments of the invention.

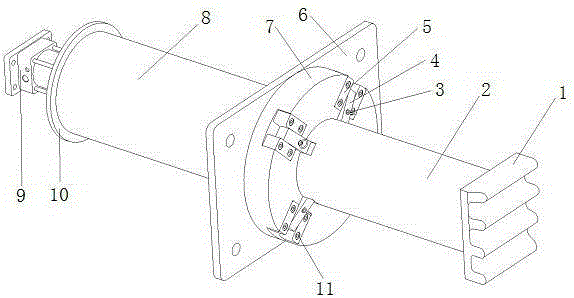

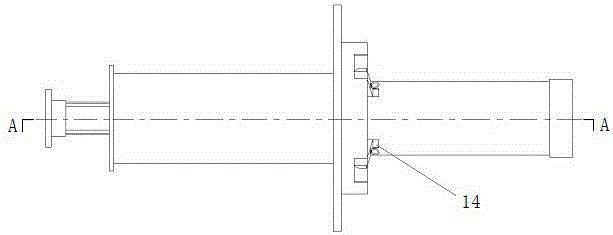

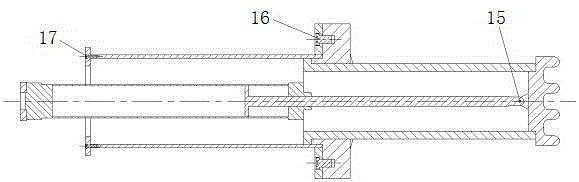

[0032] The utility model relates to a retractable rail vehicle collision energy absorbing device, which is composed of two sets of mechanisms acting independently, which are respectively installed on both sides of the vehicle end. Such as figure 1 and figure 2 As shown, the mechanical structure of the energy-absorbing device consists of anti-climbing teeth 1, energy-absorbing round tube 2, pull ring 3, cutter 4, cutter fixing block 5, mounting seat 6, cutter holder 7, guide cylinder 8, double-acting cylinder 9, rear seat 10, bolt 11, torsion spring 12 and pin 13 form. The energy-absorbing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com