Relocatable self-elevating drilling production platform and self-installing and recycling method thereof

A production platform, self-elevating technology, applied in the direction of floating buildings, etc., can solve the problems of high cost of construction, construction and disposal of protection platforms, inability to effectively support and protect water risers, and non-reusable equipment and facilities. The number of platform facilities, the effect of reducing the risk of towing at sea and ensuring the stability of towing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

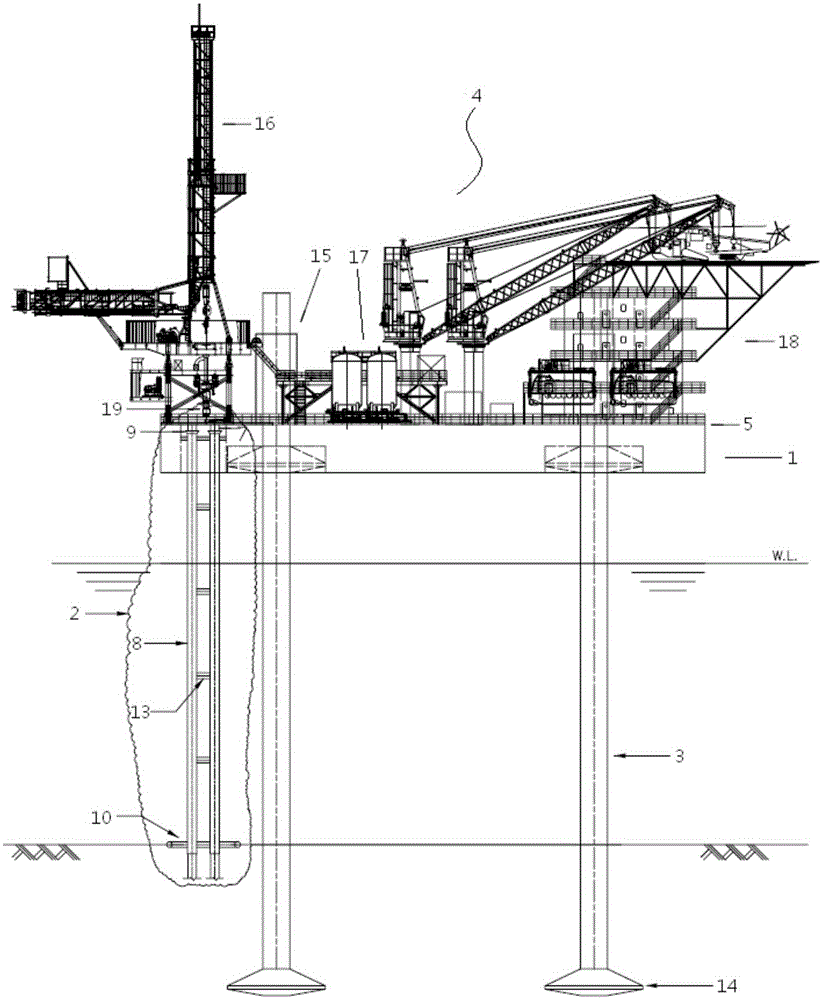

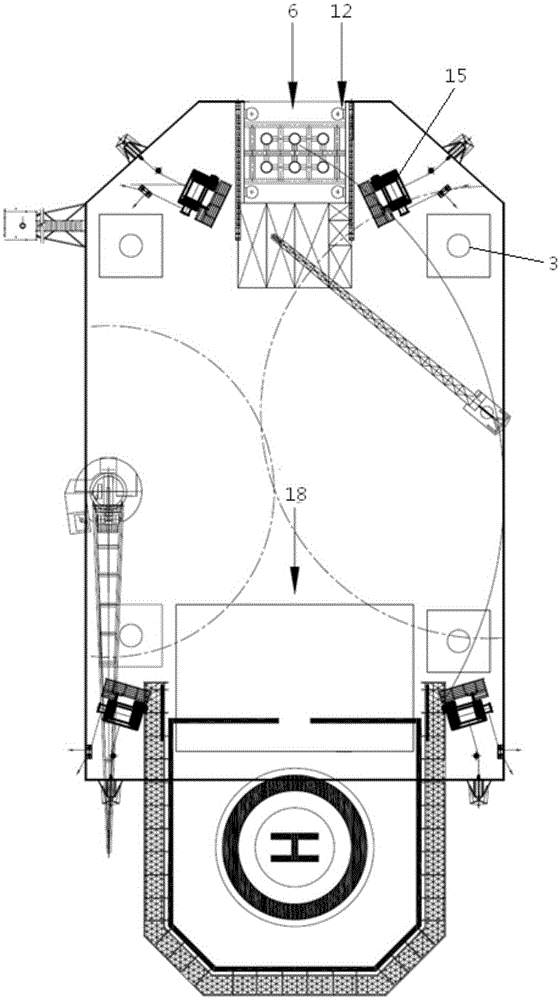

[0026] Such as figure 1 , figure 2 As shown, the present invention includes an upper box platform 1 , a waterproof casing support and protection mechanism 2 , pile legs 3 and a drilling block 4 . Wherein, the top surface of the upper box platform 1 is laid with a main deck 5 , and the upper block 4 is arranged on the main deck 5 . A wellhead area 6 for drilling is provided at the stern of the upper box platform 1 , and the water-resisting casing support and protection mechanism 2 and the water-resisting casing 7 are installed in the wellhead area 6 .

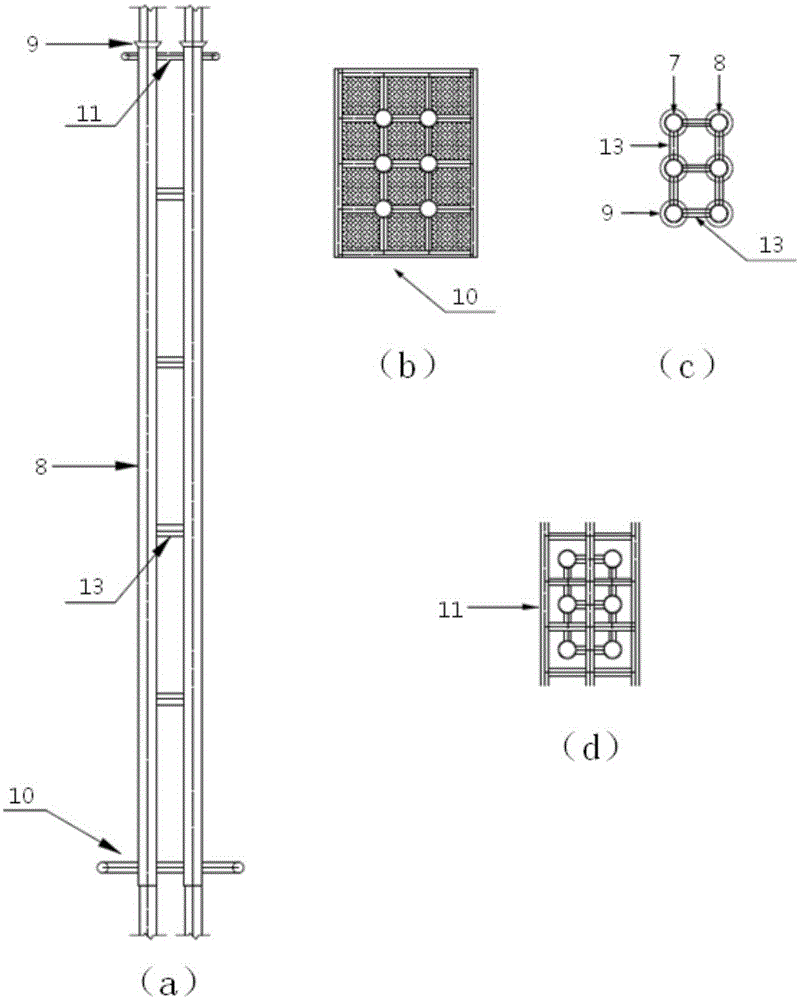

[0027] The water riser support and protection mechanism 2 includes several vertical steel round pipes 8 (the number of vertical steel round pipes 8 is equal to the number of the water riser pipes 7 to be supported), several bell mouth guides 9, An anti-settling plate 10, a horizontal layer 11 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com