Method for preparing cementing material by using washed waste incineration fly ash and application of cementing material

A technology for waste incineration fly ash and cementitious materials, applied in the field of building materials, can solve problems such as environmental hazards, environmental and human activities, and achieve the advantages of reducing the use of cement, good compressive and flexural strength, and saving treatment and disposal costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of utilizes washing rubbish to incinerate fly ash to prepare cementitious material, it is characterized in that, comprises the following steps:

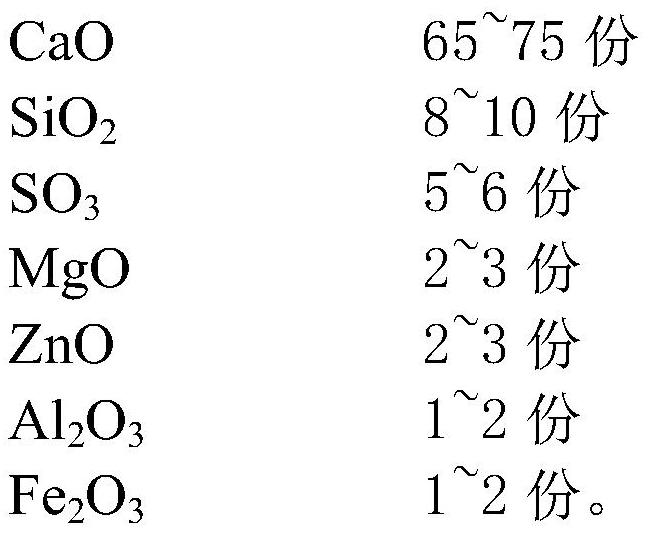

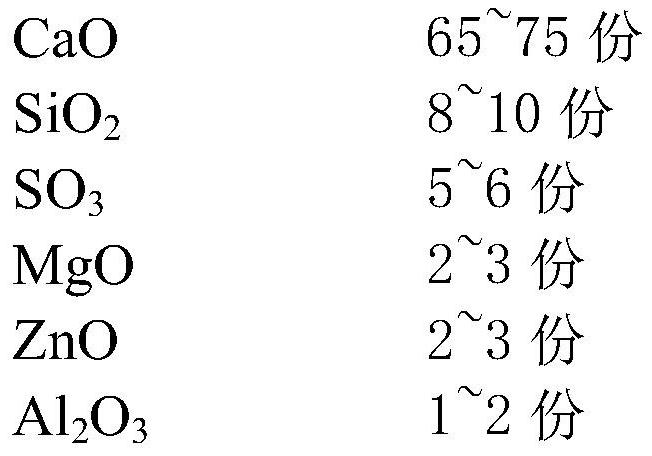

[0034] (1) Carry out washing pretreatment to fly ash to remove chlorine ion; The parts by weight of each main component of washing waste incineration fly ash are as follows: CaO 70 parts, SiO 2 9 servings, SO 3 5 parts, MgO 2 parts, ZnO 2 parts, Al 2 o 3 1 Fe 2 o 3 1 part, 1 part containing chloride ion substances.

[0035] The water washing treatment is carried out in a water washing device. The water washing process conditions are a solid-to-liquid ratio of 1:10, a water washing time of 10 minutes, and an oscillation rate of 110 r / min. The chloride ion content of the fly ash after water washing is less than 2%.

[0036] (2) dehydrating and drying the mixture treated in step (1);

[0037] (3) The dry washed fly ash in the step (2) is broken and set aside;

[0038] (4) Prepare cementitious material with the ...

Embodiment 2

[0040] The utility model relates to a cementitious material which utilizes water-washed garbage incineration fly ash for the preparation of mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com