Filling gel material for mines

A technology for filling glue and mines, applied in the field of mine filling cementitious materials, to reduce the use of cement, reduce filling costs, and solve the effects of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

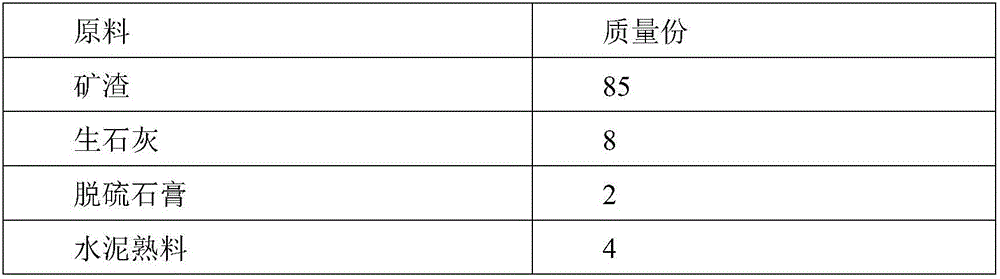

[0026] A kind of mine filling cementitious material, its each component and ratio are as shown in table 1 below:

[0027] Table 1 Example 1 Mine filling cementitious material

[0028] raw material

Embodiment 2

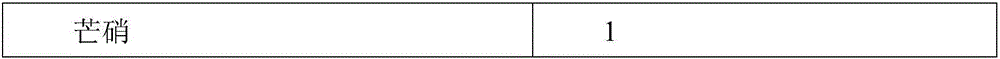

[0030] A kind of mine filling cementitious material, its each component and ratio are as shown in table 2 below:

[0031] Table 2 Example 2 Mine filling cementitious material

[0032] raw material

Embodiment 3

[0034] A kind of mine filling cementitious material, its each component and ratio are as shown in table 3 below:

[0035] Table 3 Example 3 Mine filling cementitious material

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com