A conveying mechanism for a floor solid wood core board grinding device

A technology of conveying mechanism and solid wood core, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., which can solve the problems of troublesome picking, manual picking and handling, and low efficiency of manual grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

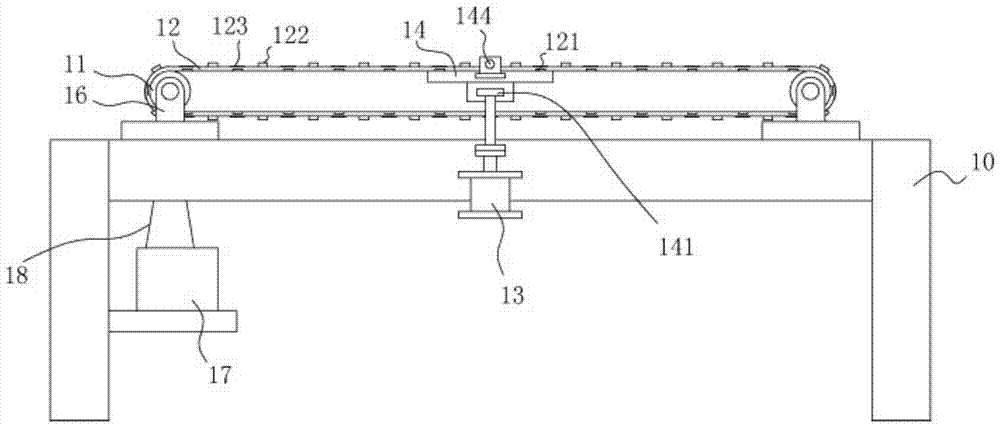

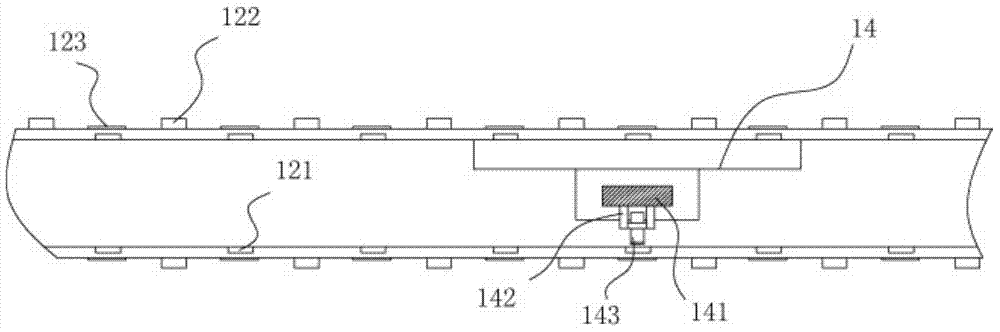

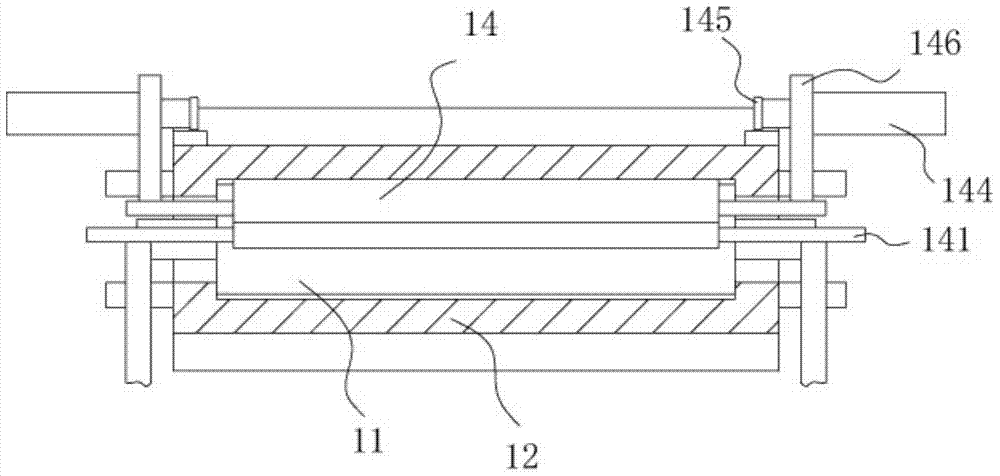

[0016] Example: see Figures 1 to 3 As shown, a conveyor mechanism for a floor solid wood core board grinding device includes a bottom conveyor frame 10, two transmission rollers 11 are hinged on the top surface of the bottom conveyor frame 10, and a conveyor belt 12 is tensioned between the two transmission rollers 11. On, both sides of the middle part of the bottom conveyor frame 10 are fixed with a push cylinder 13, and the push rod of the push cylinder 13 is fixed with a push block 14, and the push block 14 is on the back side of the middle part of the conveyor belt 12, and the front and rear sides of the push block 14 are fixed with Clamping cylinder 144, clamping block 145 is fixed on the push rod of clamping cylinder 144, and two clamping blocks 145 are above the front and rear sides of conveyor belt 12;

[0017] A plurality of protruding strips 122 are evenly distributed on the outer wall surface of the conveying belt 12, and the front and rear parts of the conveying b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com