Secondary protection device for receiving plate of ship unloader

A protection device, ship unloader technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of wire rope breakage, uncontrolled falling of the splice plate, and vicious accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

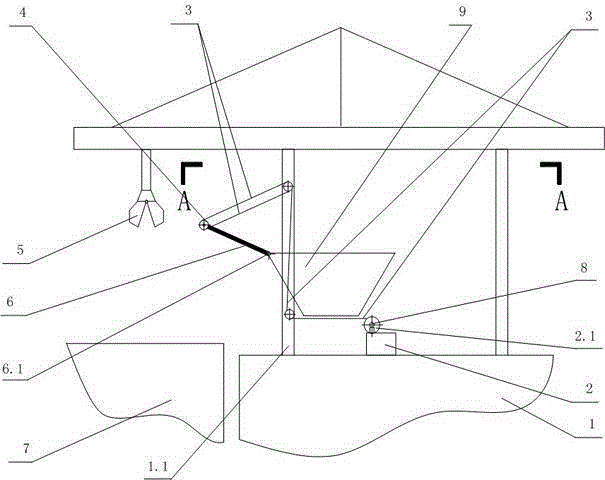

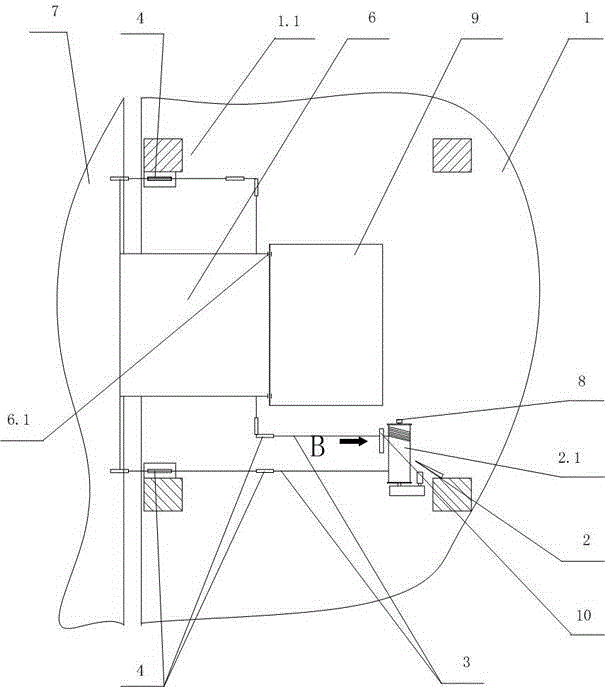

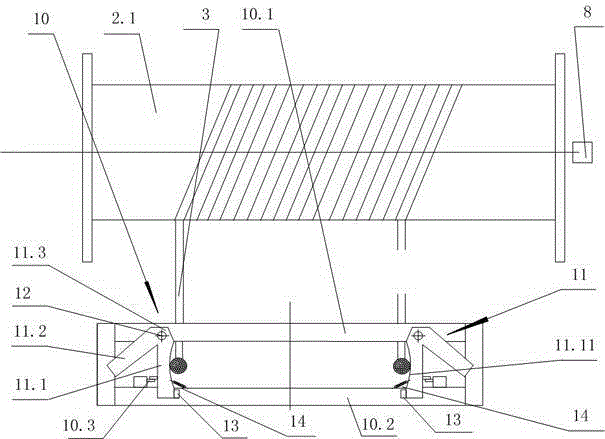

[0021] figure 1 Among them, the column 1.1 supports the ship unloader installed on the wharf 1, and uses the ship unloading grab bucket 5 to grab the materials carried in the cabin of the cargo ship 7 and transfer them to the upper mouth of the large funnel 9, then open it, and then fall to the process belt conveyor below the large funnel 9 to the rear yard. The large-scale receiving plate 6 (referring to that) of useful steel plate is installed on the seaside side of ship unloader big funnel 9 figure 2 ), the support shaft at one end of the receiving plate 6 is hinged and installed on the seaside edge of the large funnel 9 through the support sleeve 6.1. After the cargo ship 7 docks at the wharf 1, the wire rope 3 on the hoist 2 of the ship unloader passes through a plurality of pulleys 4 installed at both ends of the ship unloader and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com