A pump for a small lead-based reactor

A lead-based reactor, small-scale technology, applied to pumps, components of pumping devices for elastic fluids, pump components, etc., can solve the problem of large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

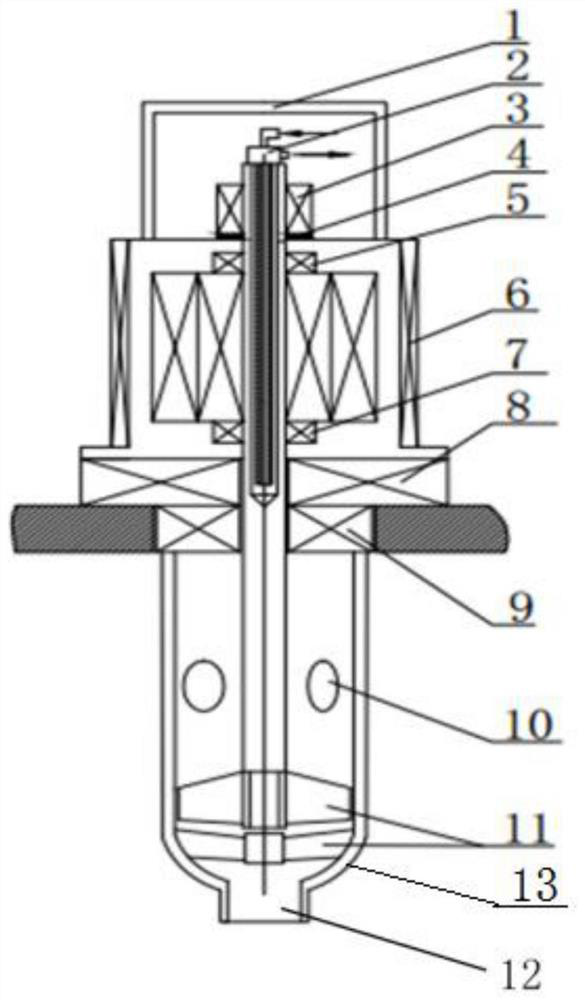

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] A kind of small lead-based reactor pump of the present invention comprises:

[0026] The motor is used to drive the hydraulic components in the pump casing to rotate, and the motor is fixed by the upper support 5 of the motor and the lower support 7 of the motor;

[0027] Motor cooling cavity 6, the motor cooling cavity 6 is set outside the motor, used for cooling the heat generated when the motor is working;

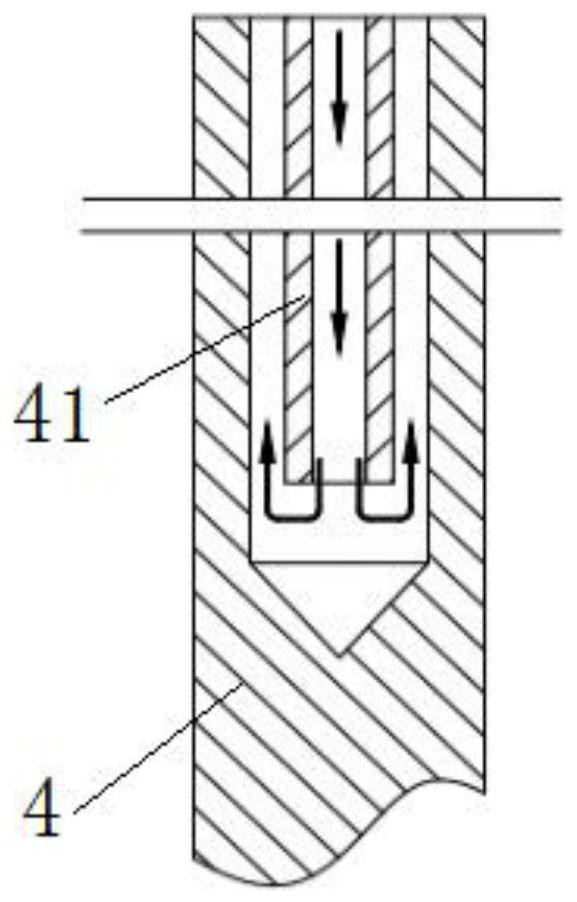

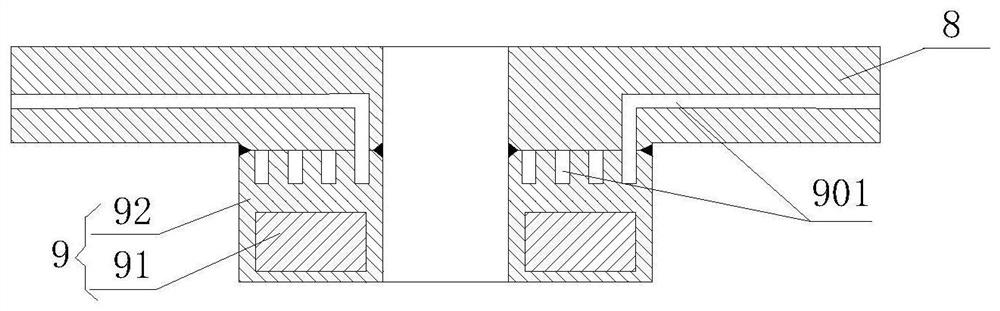

[0028] A pump casing 13, a hydraulic component 11 is arranged in the pump casing 13, a hollow shaft 4 is installed on the motor, the hollow shaft 4 runs through the upper support 5 of the motor and the lower support 7 of the motor, and one end of the hollow shaft 4 is inserted into the pump casing 13 to interact with the hydraulic The parts 11 are connected, the outer wall of the pump casing 13 is provided with a pump inlet 10 , and the bottom of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com