System pipe fitting for impounding, percolating, utilizing and draining sponge urban rainwater and construction method of system pipe fitting

A sponge city and rainwater technology, applied in waterway systems, sewer systems, chemical instruments and methods, etc., can solve the problems of increasing the volume of municipal pipe networks, large construction costs, and increasing pipelines, so as to alleviate urban waterlogging and facilitate construction. , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

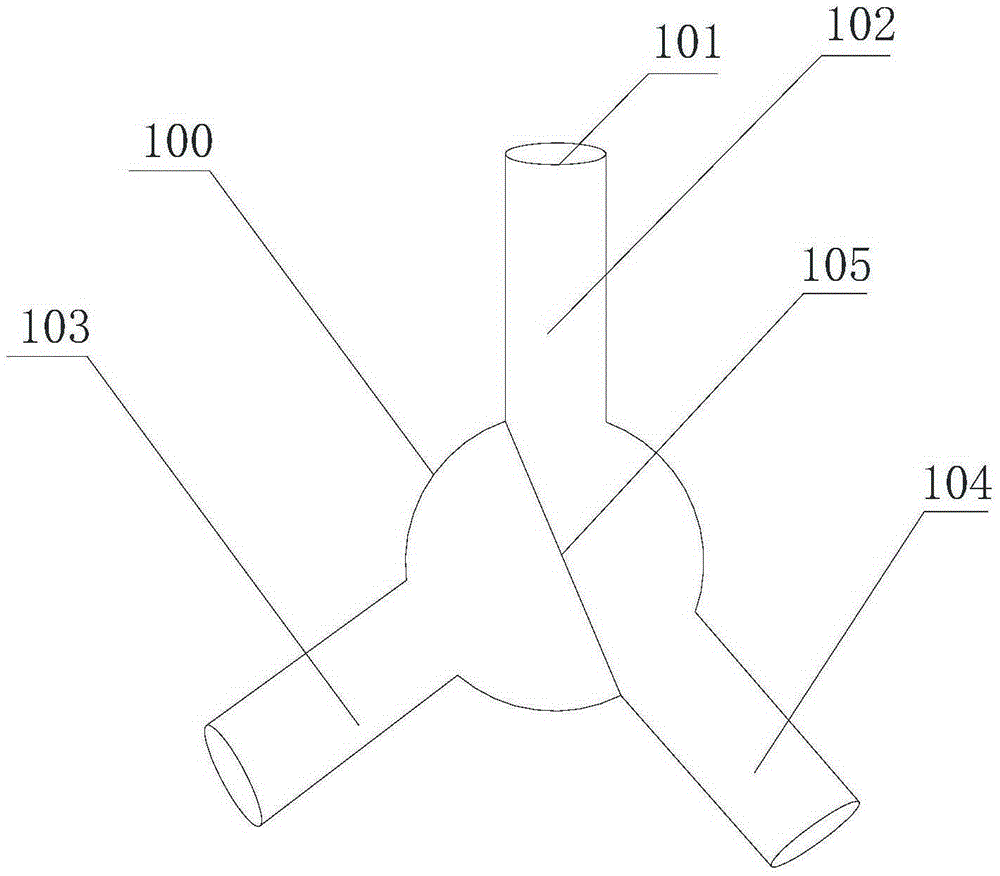

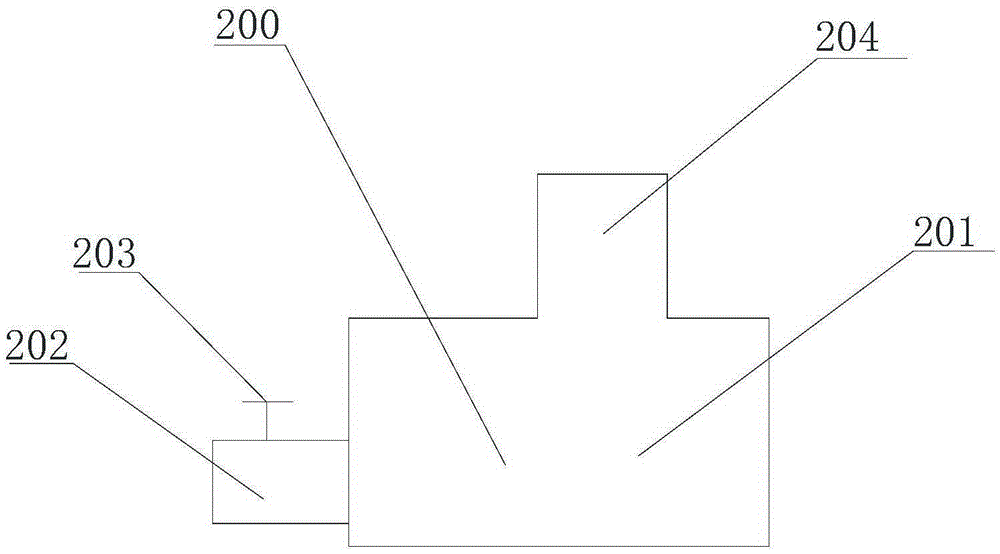

[0040] see figure 1 and figure 2 , this embodiment provides a drainage system pipe fitting for rainwater stagnation, infiltration and purification in a sponge city. There are three pipes, one of which is the water collecting member 100 arranged upstream for collecting and treating rainwater on the road surface, and the other is the seepage drainage member 200 arranged downstream for storing the rainwater collected and treated by the water collecting member 100, wherein The water collecting member 100 is provided with a water collecting port 101, and the rainwater on the road enters the water collecting member 100 through the water collecting port 101, and the rainwater is processed in the water collecting member 100. 200 is connected, and the other is connected with the drainage pipe. The clear water treated by the water collection member 100 enters the seepage and drainage member 200, and the treated sewage is discharged through the drain pipe, so as to avoid sewage polluti...

Embodiment 2

[0047] The basic structure, principle and technical effect of the drainage system pipe fittings for rainwater stagnation and infiltration provided in this embodiment of the sponge city are the same as those of the first embodiment. For a brief description, what is not mentioned in this embodiment can be Refer to the corresponding content in the first embodiment.

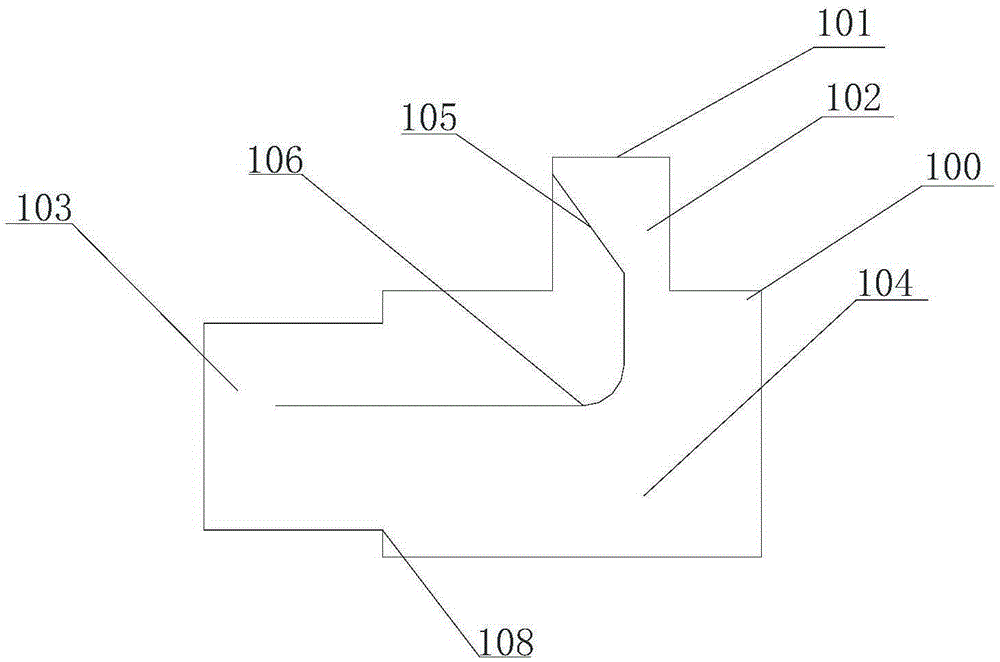

[0048] see image 3 , Figure 4 and Figure 5 In the present embodiment, the preferred shunt pipe 102 communicates with the inner wall of the discard pipe 104, the clear water pipe 103 communicates with the discard pipe 104 and the axes of the two coincide, and the shunt is set at the position where the discard pipe 104 and the shunt pipe 102 are connected. Divider plate 106, diverter plate 106 divides the end of diversion pipe 102 into two outlets, wherein one side of diversion plate 106 and diversion pipe 102 form a clean water outlet, and the other side of diversion plate 106 and diversion pipe 102 form a sewage...

Embodiment 3

[0052]The basic structure, principle and technical effect of the drainage system pipe fittings for rainwater stagnation and infiltration provided in this embodiment of the sponge city are the same as those of the second embodiment. For a brief description, what is not mentioned in this embodiment can be Refer to the corresponding content in the second embodiment.

[0053] In this embodiment, on the basis of the second embodiment, water seepage ports are respectively provided on the water collection member 100 and the seepage drainage member 200, and a first water seepage port 110 is provided on the jettison pipe 104, and the first water seepage port 110 is arranged on Above the baffle plate 109, the first seepage port 110 is provided with a first seepage net, which is used to slowly infiltrate when there is too much rainwater in the jettison pipe 104, so as to avoid excessive rainwater in the jettison tube 104 At the same time, the second water seepage port 205 is set on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com