Prevention method for foundation pit retaining structure hole-punching and water-gushing caused by blast of stratum with soft upper portion and hard lower portion

A technology for foundation pit enclosure and enclosure structure, which is applied in the direction of foundation structure engineering, excavation, protection devices, etc., and can solve problems such as ineffective sealing of cavities and secondary water gushing easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

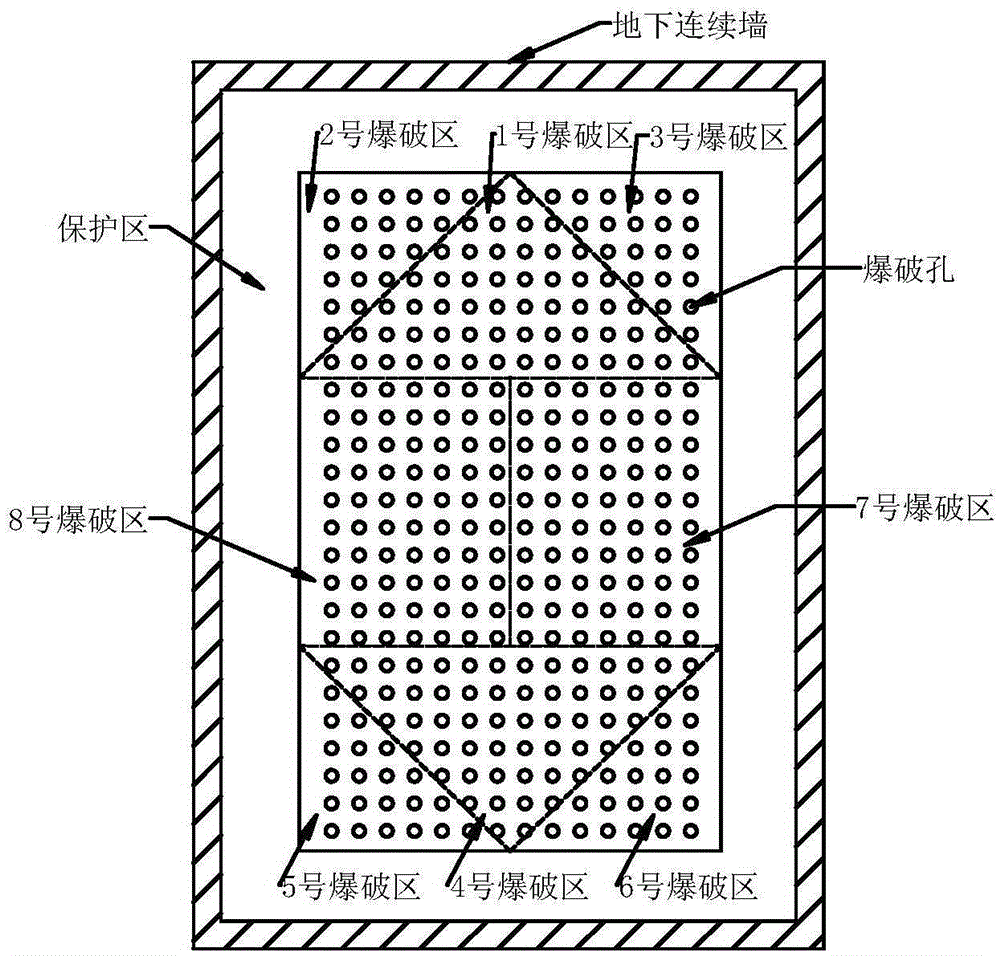

[0094] A subway station is planned to be built in Huadu District, Guangzhou City. The construction pit is 80m long, 40m wide and 25m deep.

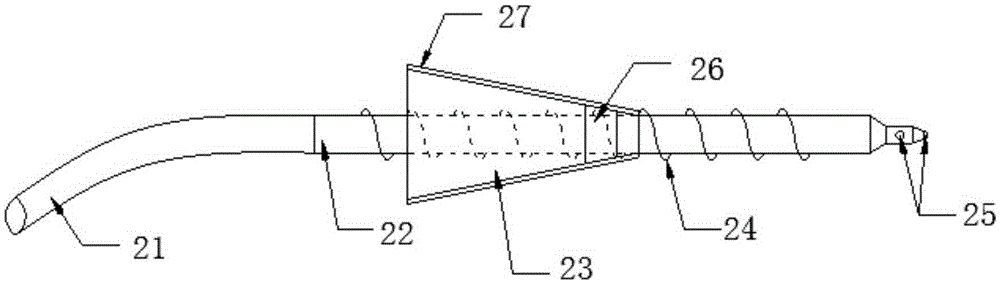

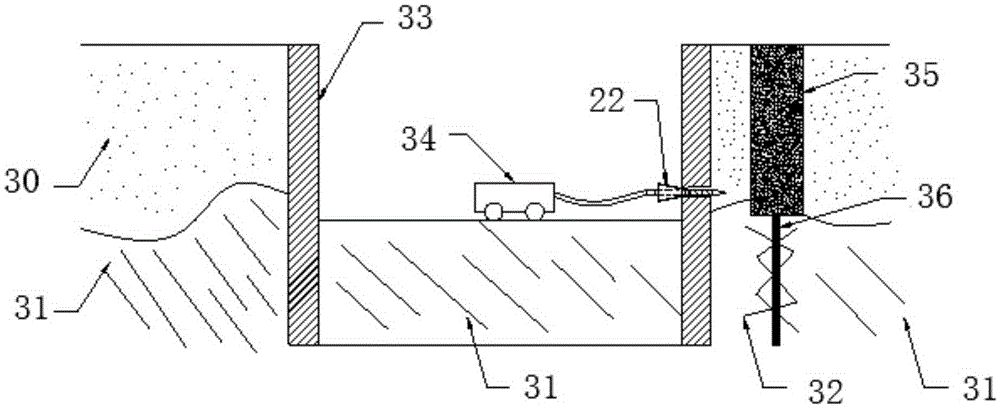

[0095] This embodiment provides a method for prevention and control of water gushing through holes in foundation pit enclosures caused by blasting in upper soft and lower hard strata. The specific construction steps of the construction method are as follows:

[0096] Step 1. Determine the geological conditions of the construction site;

[0097] Consult the geological survey report and confirm that the buried depth of the rock face in the construction area is 14m, and the initial water level of the groundwater is -1m.

[0098] In this example, the overlying soil layer is a sandy soil layer with a thickness of 14m and a sandy soil weight of 18kN / m 3 , the depth of the foundation pit is mainly composed of slightly weathered limestone, and the distribution value of the unconfined compressive strength is between 60 and 80 MPa.

[0099]In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com