Pitched roof skylight structure

A technology of sloping roofs and skylights, applied in the field of machinery, can solve the problems of failure to consider climate characteristics, complex structure of skylights, and easy water accumulation, etc., and achieve the effect of maintaining long-term performance, good integrity, and enhancing water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The application will be described in further detail below in conjunction with the accompanying drawings.

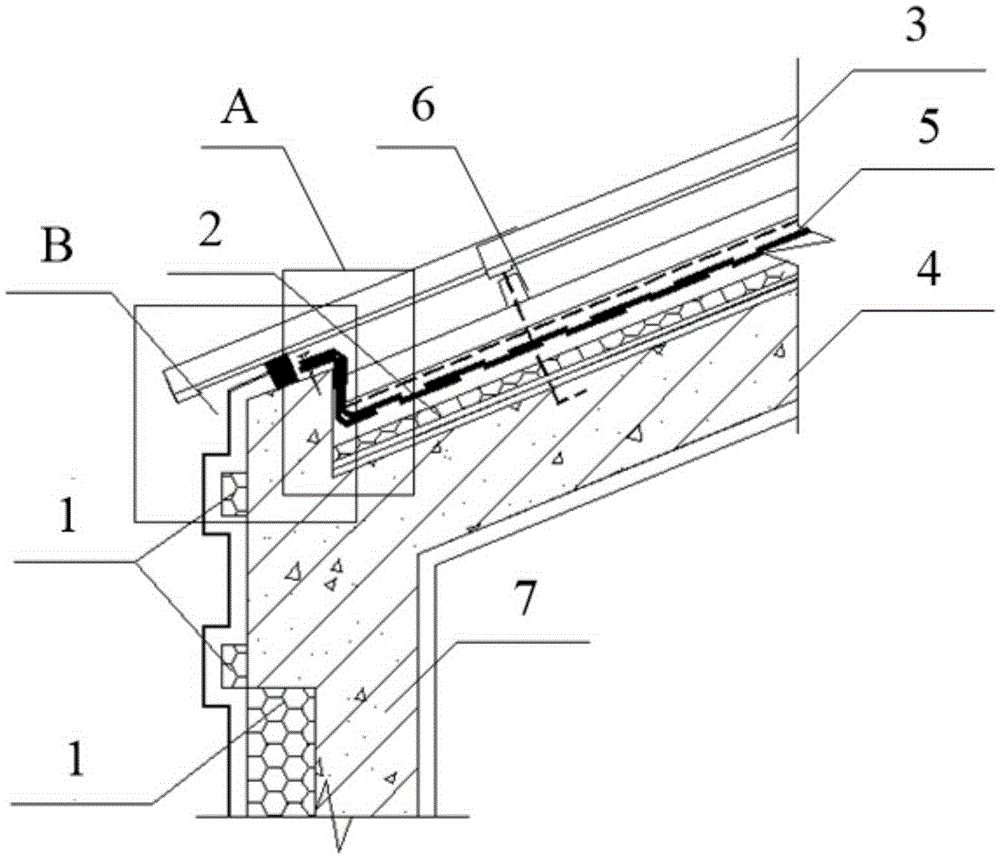

[0025] figure 1 A schematic structural diagram of a skylight on a pitched roof provided according to one aspect of the present application is shown. combine figure 1 , one aspect of the present application provides a sloping roof skylight structure, including:

[0026] The side wall of the skylight, the side wall of the skylight has a first insulation layer 1, and the first insulation layer is a graphite polystyrene insulation board;

[0027] The roof of the skylight, the roof of the skylight is fixedly connected with the side wall of the skylight, the roof of the skylight is inclined downward toward the side wall of the skylight, the roof of the skylight has a second insulation layer 2, and the second insulation layer is graphite polymer Styrene insulation board;

[0028] The cover tile 3, the cover tile 3 completely covers the roof of the skylight and the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap