High-strength installation chassis structure of finished vertical hinged door window frame

A technology for installing chassis and swinging doors and windows. It is applied in the direction of window/door frame, base frame, window/door, etc. It can solve the problems of product design expectations that are far apart, wall materials are not uniform, and increase the burden on customers. Consistency and stability, clear and simple definition of standards, and the effect of ensuring long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0143] The present invention will be further described below in conjunction with specific examples.

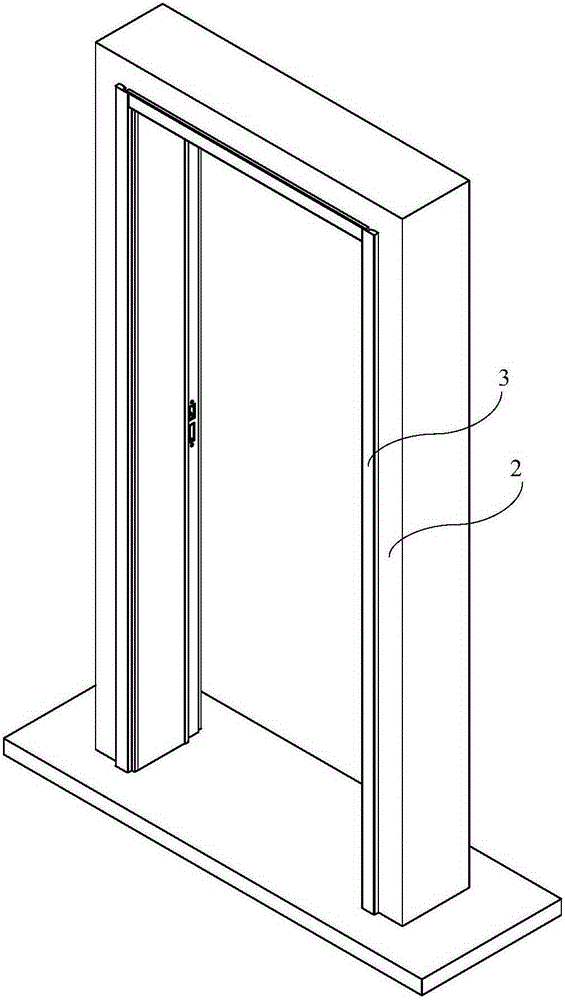

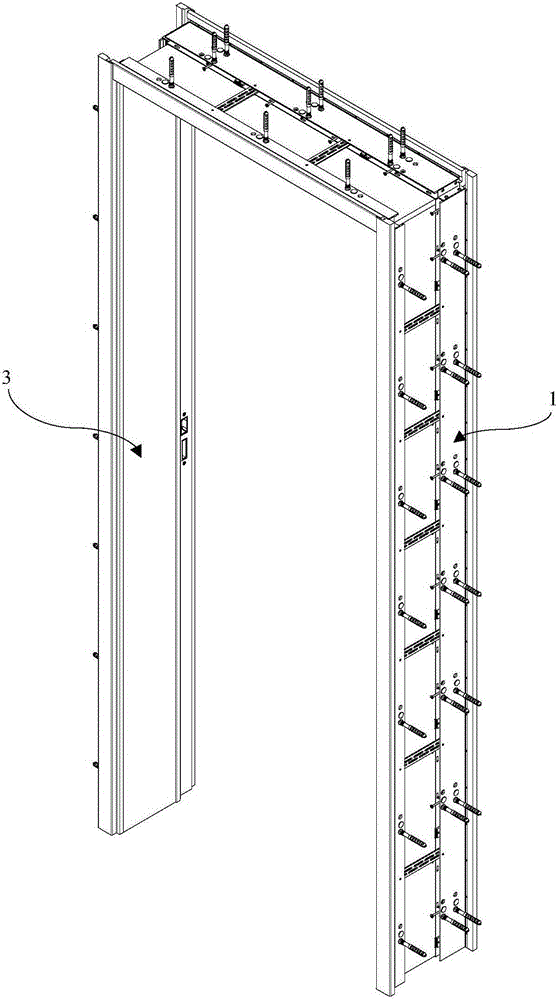

[0144]In the first preferred embodiment of the present invention, when a finished casement door and window frame is used as a door frame, please refer to Figure 1-3 , the door and window frame 3 is installed in the door and window hole 2 of the main body of the building in a position-adjustable manner through the chassis 1 .

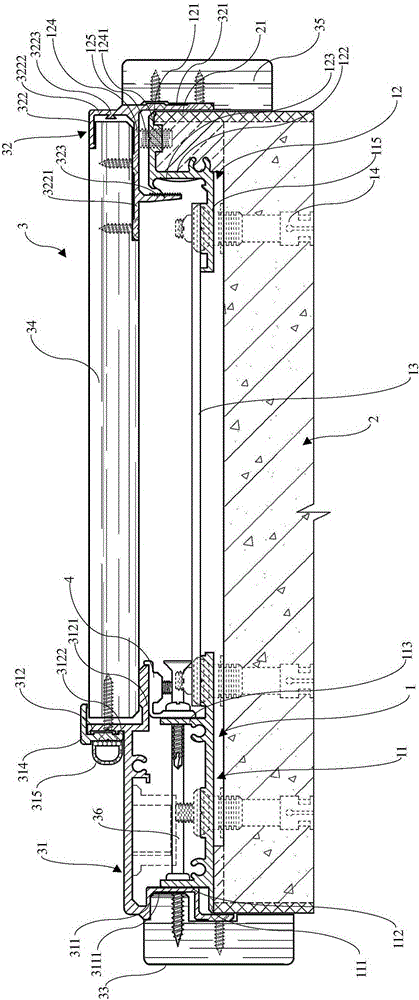

[0145] see Figure 3-8 , the installation chassis 1 includes a first frame body 11 and a second frame body 12, along the first frame body 11 and the second frame body 12, a number of adjusting and fastening areas A are arranged respectively, and the installation is performed by adjusting the fastening areas A The chassis 1 exerts a first force along the fastening direction and a second force opposite to the first force direction, and the chassis 1 is installed through the cooperation of the first force and the second force. Make position adjustments a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com