Lubricating equipment for strip parts

A technology for lubricating equipment and parts, applied in mechanical equipment, engine lubrication, engine components, etc., can solve the problems of cumbersome coating process, poor moisturizing effect, uneven coating, etc., and achieves simple and compact structure, low manufacturing cost, and use easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

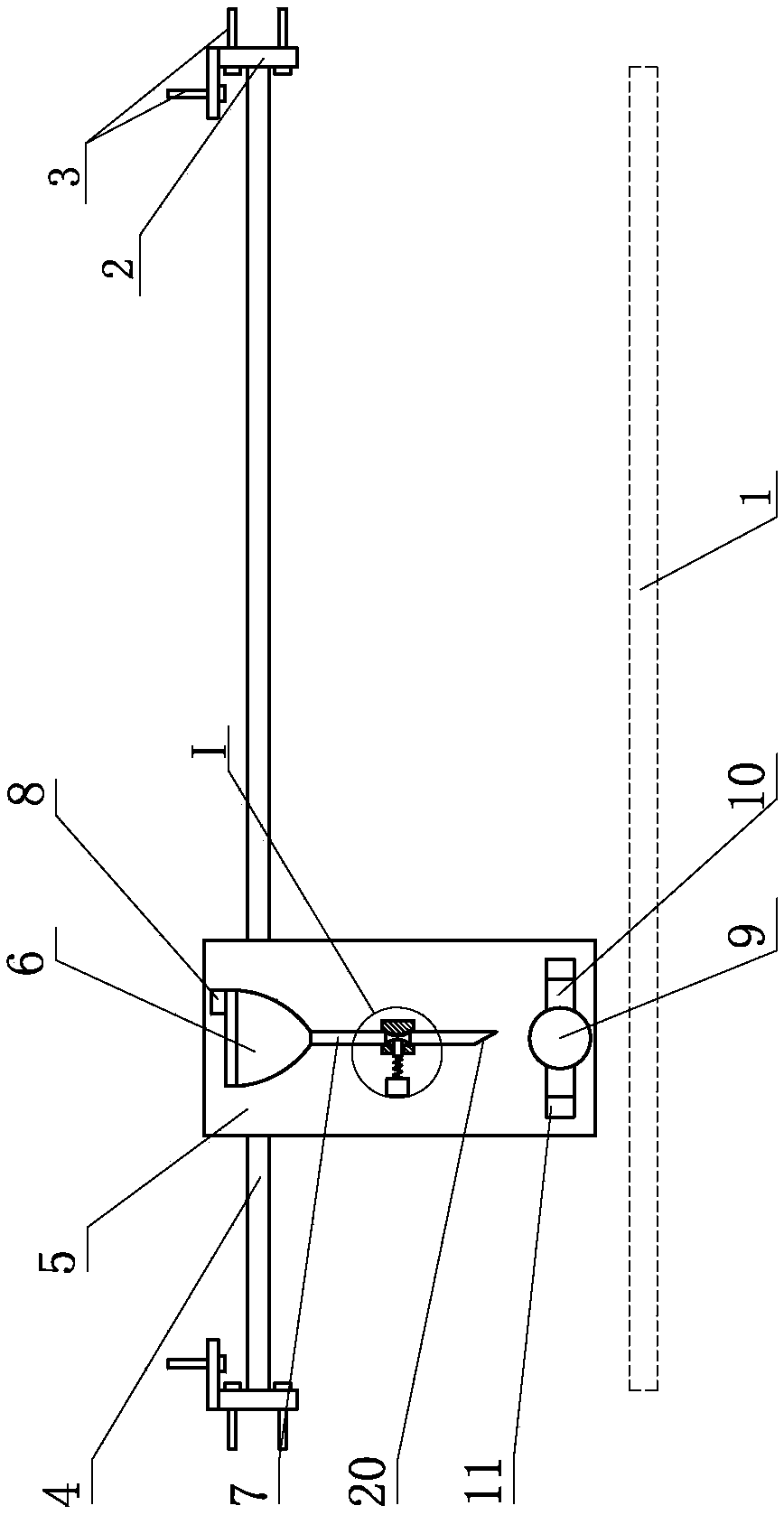

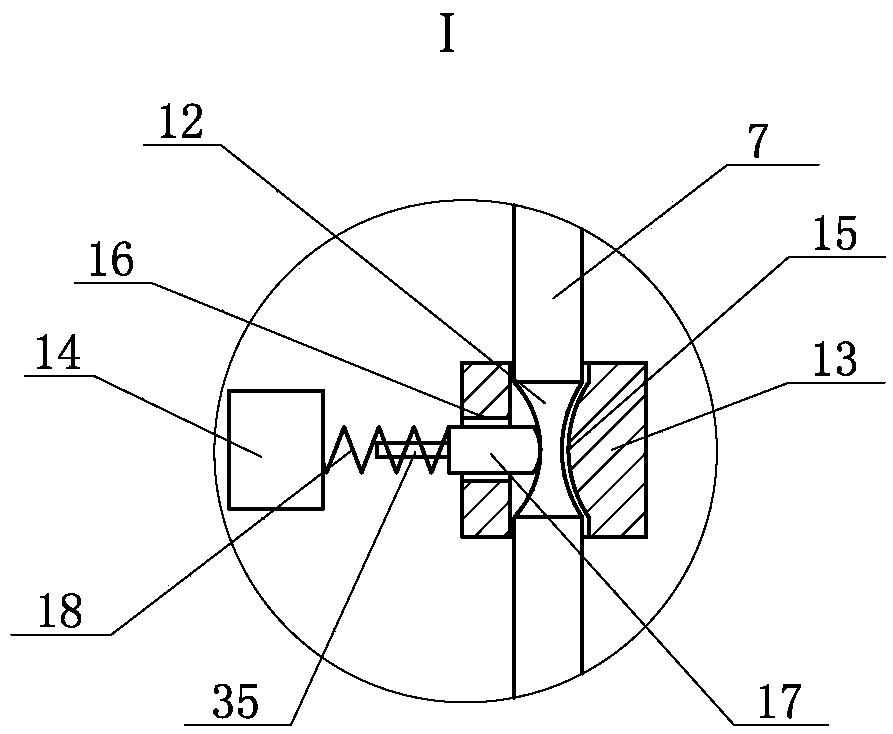

[0009] A kind of lubricating equipment for strip parts, such as figure 1 and figure 2 As shown, it includes a transverse guide rail 4, the transverse guide rail 4 is parallel to the bar-shaped part 1, the transverse guide rail 4 is located on the top of the bar-shaped part 1, and the horizontal guide rail 4 is provided with a movable seat 5 that can move horizontally, and an oil pot 6 is installed on the movable seat 5 , the top of the oil pot 6 is provided with vent holes 8, the lower end of the oil pot 6 is provided with a connected oil pipe 7, the bottom of the moving seat 5 is provided with a rotating disk 9 with a rotating motor, and connecting rods 10 are installed at the two ends of the rotating disk 9. An oil brush 11 is installed at the end, and the oil brush 11 can cooperate with the lower opening of the oil pipe 7; the middle part of the oil pipe 7 is a flexible pipe 12, and the middle part of the moving seat 5 is provided with a valve sleeve 13 and an electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com