Apparatus and method for testing thermal resistance of textile structure radiator

A textile structure and testing device technology, which is applied in the field of testing devices for the thermal resistance of textile structure radiators, can solve the problem of low flatness of the bottom surface, cannot meet the evaluation requirements for the heat dissipation performance of textile structure radiators, and cannot meet the requirements for testing the heat dissipation of textile structure radiators. Resistance requirements and other issues to achieve the effect of ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

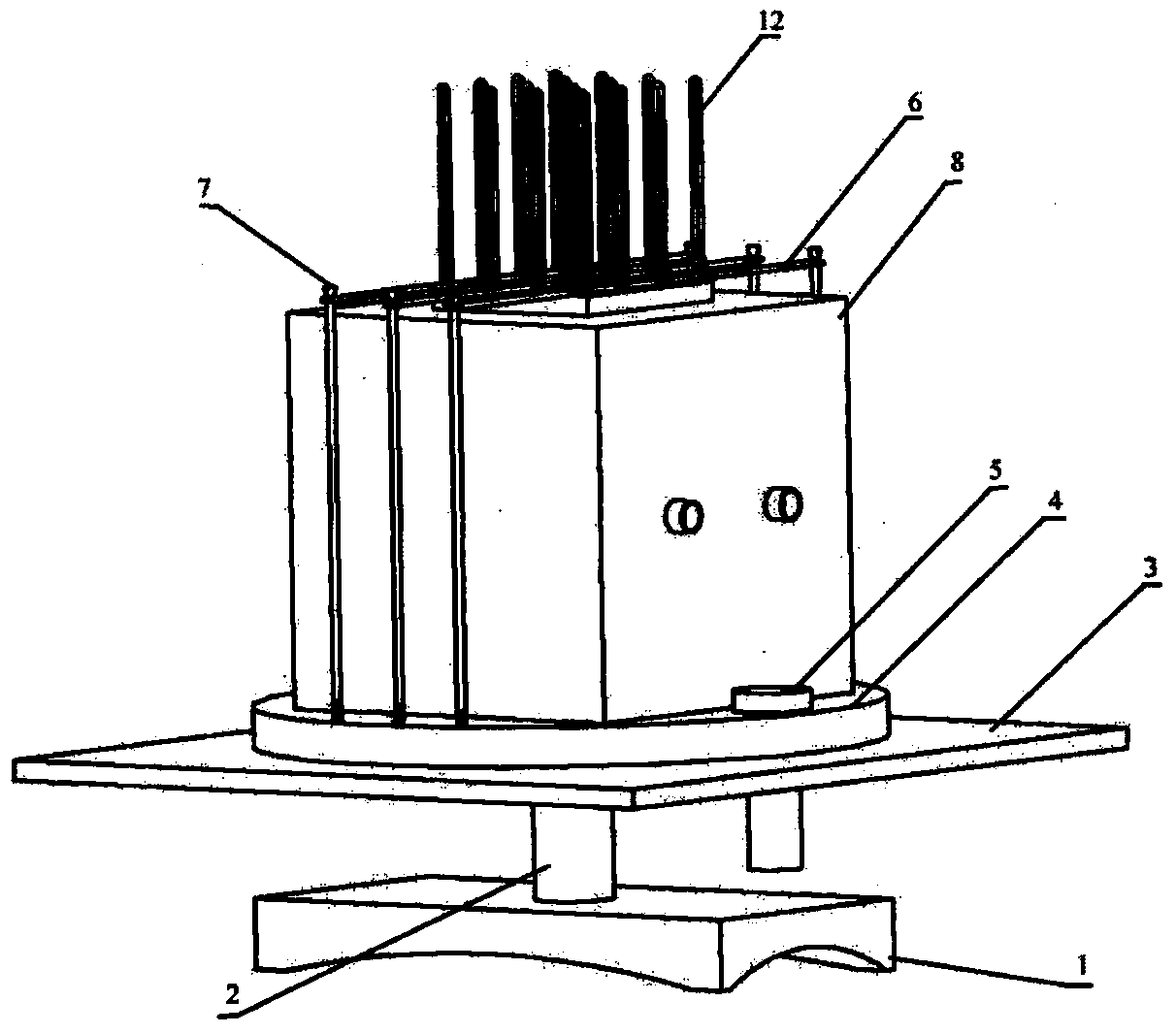

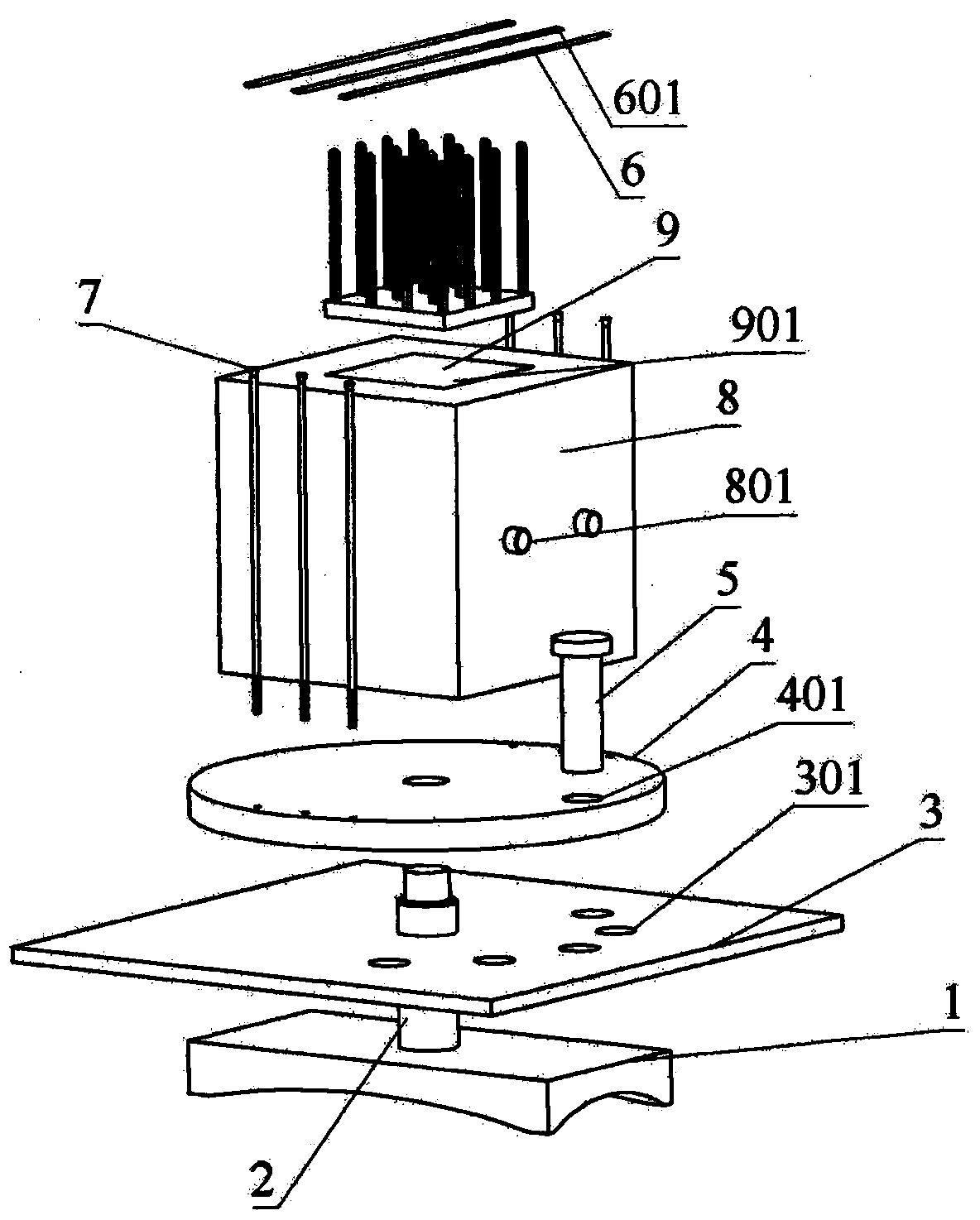

[0033] figure 1 The schematic diagram of the thermal resistance testing device of the textile structure radiator provided in this embodiment, the thermal resistance testing device of the textile structure radiator includes a rotating device, a fixing device and a heat source device, the heat source device is arranged on the rotating device, and the upper surface of the heat source device is arranged The heat sink of the textile structure to be tested and fixed by the fixing device.

[0034] Wherein, the rotating device is composed of a base 1, a support shaft 2, a fixed disc 3 and a rotating disc 4, etc., one end of the supporting shaft 2 is fixed to the base 1, the other end of the supporting shaft 2 passes through the fixed disc 3 and is connected to the rotating disc 4, and the rotating disc 4 It can rotate around the supporting axis 2.

[0035] The base 1 and the support shaft 2 are fixed through their own screw holes, the fixed disc 3 and the support shaft 2 can be direc...

Embodiment 2

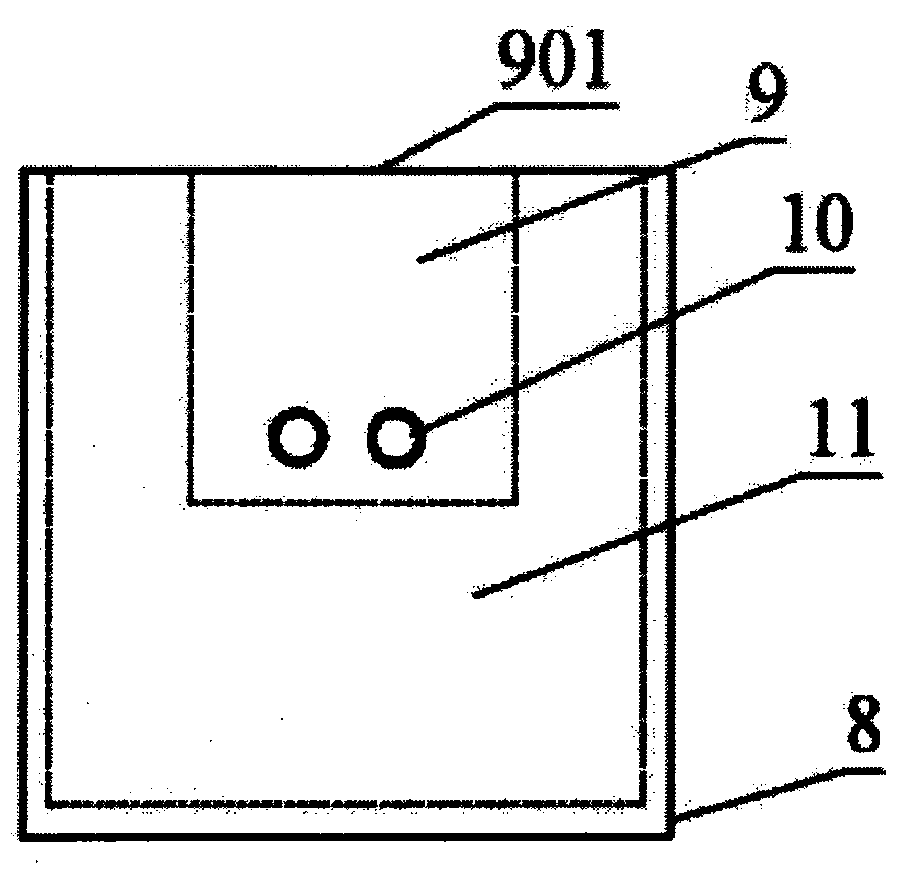

[0047] The difference between this embodiment and Embodiment 1 is that the shape of the upper surface 901 of the heating block 9 is a curved surface with a radius of curvature of 20 mm, such as Figure 6 As shown, at the same time, the middle part of the cross bar 6 is also a curved structure, and the radius of curvature is the same as that of the upper surface 901 of the heating block 9 . The textile structure radiator 12 to be tested is placed on the heating surface of the heating block 9, and the heating surface of the bottom plate of the radiator is aligned with the heating surface of the heating block, and the heat dissipation performance test of the textile structure radiator under the buckling application state of the bottom plate is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com