Discharge-free aluminum alloy cutting fluid and application method thereof

A technology of aluminum alloy and cutting fluid, applied in lubricating composition, petroleum industry, etc., can solve problems such as easy to smell, difficult to clean, scrapped, etc., and achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

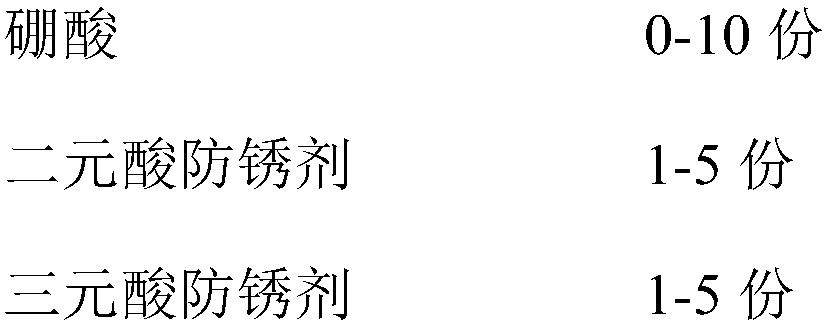

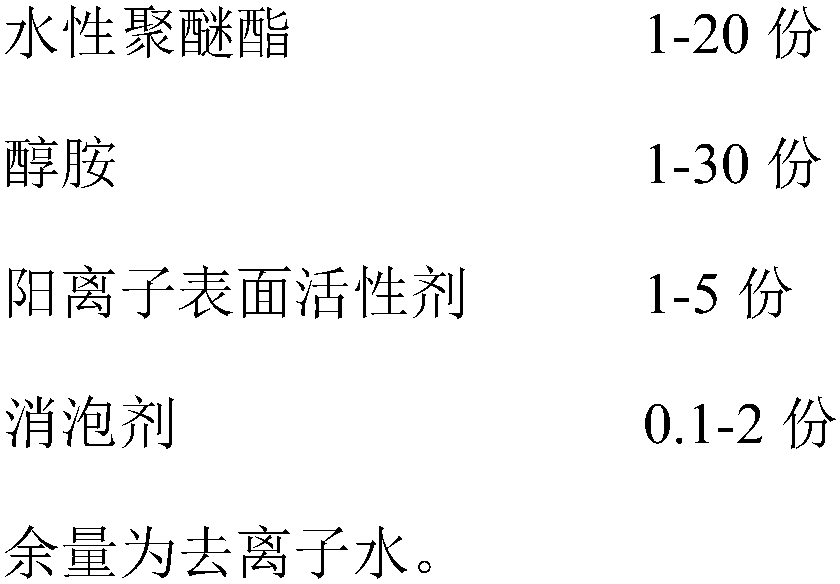

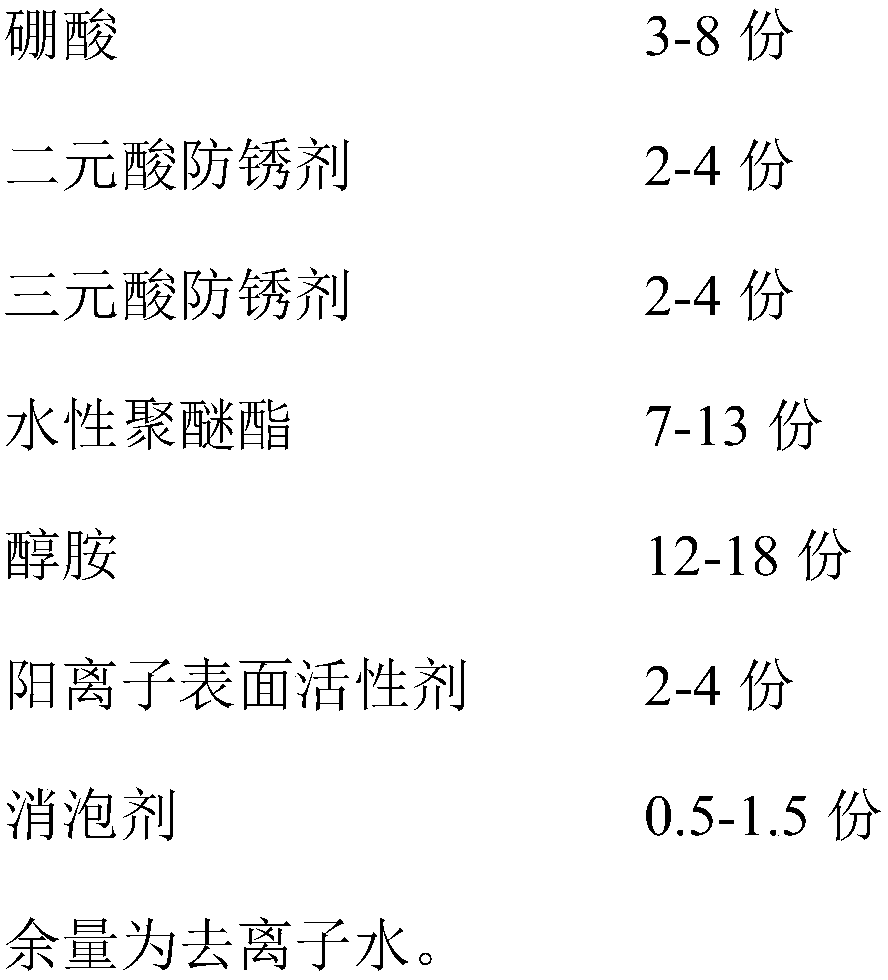

Method used

Image

Examples

Embodiment 1

[0023] The emission-free aluminum alloy cutting fluid of the present embodiment is composed of the following raw materials in parts by weight: 1 part of boric acid, 3 parts of sebacic acid, 5 parts of tribasic acid rust inhibitor, 20 parts of water-based polyether ester, 5 parts of monoethanolamine , 15 parts of triethanolamine, 1 part of cationic quaternary ammonium salt type surfactant, 0.5 part of defoamer, 49.5 parts of deionized water.

[0024] The various indicators of the emission-free aluminum alloy cutting fluid obtained in this embodiment all meet the requirements of GB / T6144, and its use method is: dilute with water by a volume ratio of 1:25 times, and use it for the grinding process of aluminum alloy; Diluted by volume ratio of 1:15 times, used for milling process of aluminum alloy; diluted by volume ratio of 1:10 times with water, used for drilling and tapping process of aluminum alloy.

Embodiment 2

[0026] The discharge-free aluminum alloy cutting fluid of the present embodiment is composed of the following raw materials in parts by weight: 10 parts of boric acid, 5 parts of sebacic acid, 3 parts of tribasic acid antirust agent, 15 parts of water-based polyether ester, 10 parts of diethanolamine , 10 parts of triethanolamine, 5 parts of cationic quaternary ammonium salt type surfactant, 2 parts of defoamer, 40 parts of deionized water.

[0027] The various indicators of the emission-free aluminum alloy cutting fluid obtained in this embodiment all meet the requirements of GB / T6144, and its use method is: dilute with water by a volume ratio of 1:30 times, and use it for the grinding process of aluminum alloy; Diluted by volume ratio of 1:20 times, used for milling process of aluminum alloy; diluted by volume ratio of 1:5 times with water, used for drilling and tapping process of aluminum alloy.

Embodiment 3

[0029] The emission-free aluminum alloy cutting fluid of the present embodiment is composed of the following raw materials in parts by weight: 3 parts of boric acid, 4 parts of sebacic acid, 4 parts of tribasic acid rust inhibitor, 13 parts of water-based polyether ester, 9 parts of monoethanolamine , 9 parts of diethanolamine, 4 parts of cationic quaternary ammonium salt type surfactant, 1.5 parts of defoamer, 52.5 parts of deionized water.

[0030] The various indicators of the emission-free aluminum alloy cutting fluid obtained in this embodiment all meet the requirements of GB / T6144, and its use method is: dilute with water by a volume ratio of 1:20 times, and use it for the grinding process of aluminum alloy; Diluted by volume ratio of 1:10 times, used for milling process of aluminum alloy; diluted by volume ratio of 1:5 times with water, used for drilling and tapping process of aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com