Cooling tower of hydrodynamic draught fan

A hydraulic fan and cooling tower technology, applied in the field of cooling towers, can solve the problems of high water pressure energy consumption, low speed of fan blades, and failure to meet the cooling effect of cooling towers, so as to meet the requirements of improving industrial energy consumption and reducing The effect of fixed costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

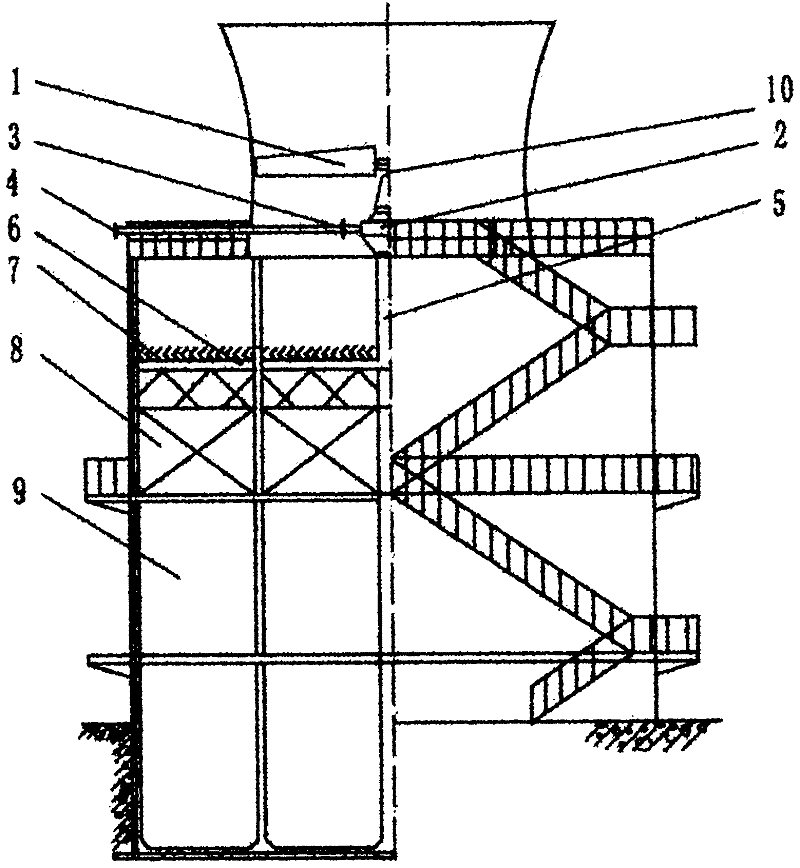

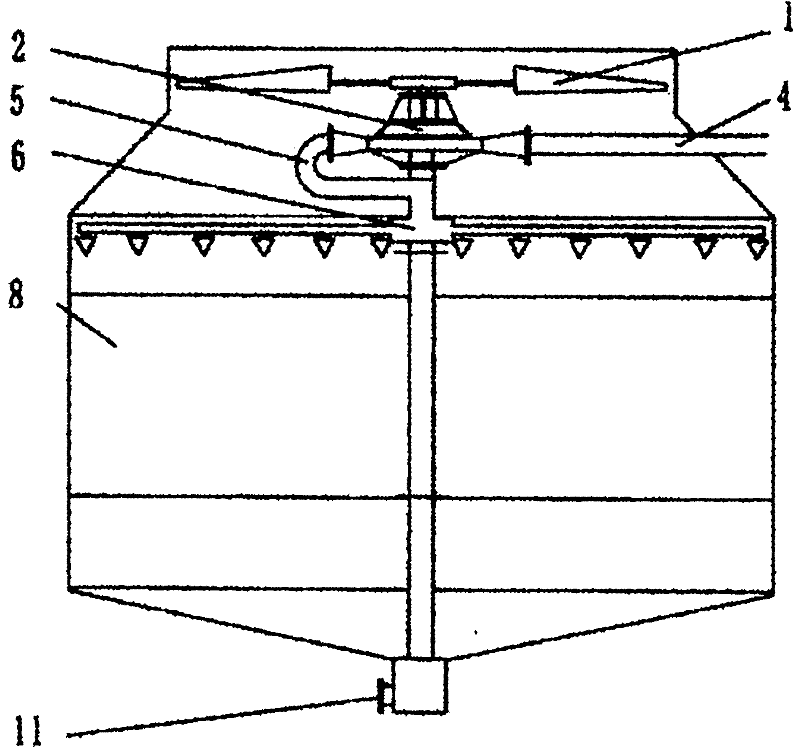

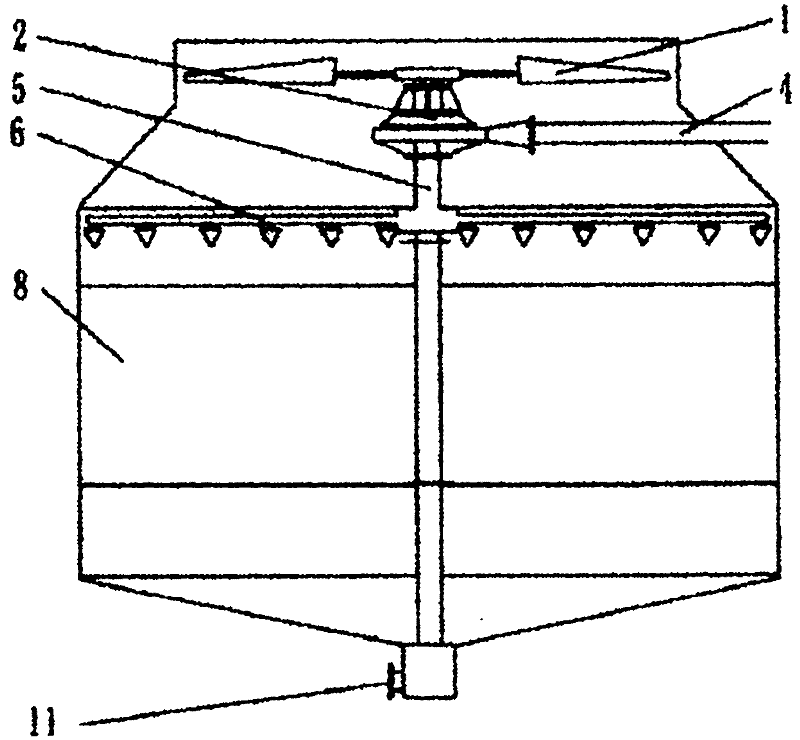

[0029] Figure 1 to Figure 9 It is a representative few of the various forms of the water driven fan cooling tower of the present invention. Figure 1 to Figure 9 1 is the fan blade; 2 is the turbine; 3 is the water inlet; 4 is the water inlet pipe; 5 is the water outlet pipe; 6 is the water distribution pipe; 7 is the water collector; 8 is the filler; 9 is the water spray area; 10 is the drive shaft ; 11 is the water outlet.

[0030] Also refer to Figure 1 to Figure 9 , The water driven fan cooling tower of the present invention will enter the circulating cooling water with proper water head and rated flow through the water inlet pipe 4, and through the water inlet 3 of the water turbine 2, the overflow water turbine 2 is converted into mechanical energy to the drive shaft 10 to drive the wind blades 1 rotates to generate air volume. The air volume is air. The water after the flow turbine 2 flows through the outlet pipe 5 to the water distribution pipe 6, spreads on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com