Speckle removing device of laser display

A laser display and speckle technology, applied in optics, optical components, instruments, etc., can solve the problem of inability to eliminate laser display speckle, and achieve the effect of improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

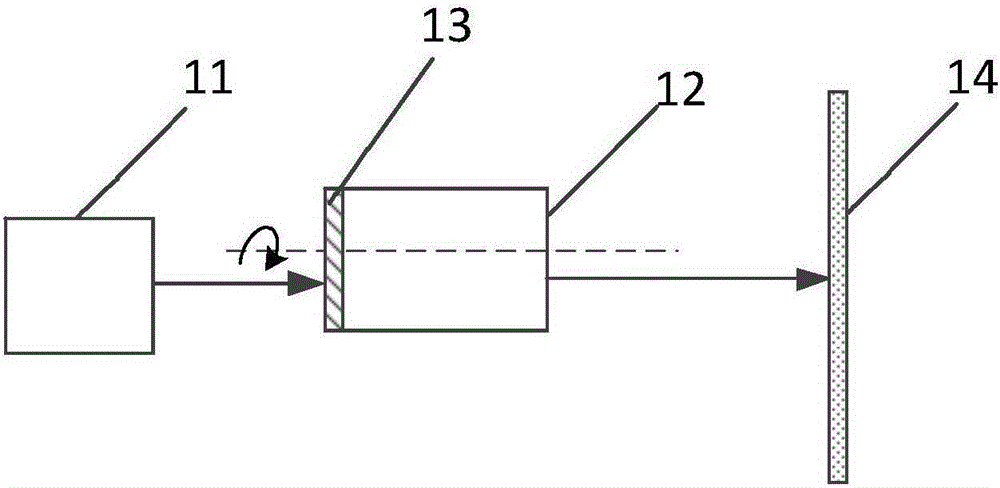

[0032] Such as figure 1 As shown, this embodiment provides a laser display speckle removal device, including: a laser light source 11 and an optical element 12 located in the light emitting direction of the laser light source 11 . In the optical element 12 , the surface facing the laser light source 11 is the laser incident surface 13 . In addition, the device preferably also includes a light screen 14 arranged in the light emitting direction, preferably a white screen. The optical screen 14 is located on the side of the optical element 12 away from the laser light source 11 . Preferably, the laser light source 11 is one or more of red semiconductor lasers, green semiconductor lasers and blue semiconductor lasers. Correspondingly, the wavelengths of each semiconductor laser are 671nm, 532nm and 473nm; the power is 3.5W, 0.32W or 1.3W respectively.

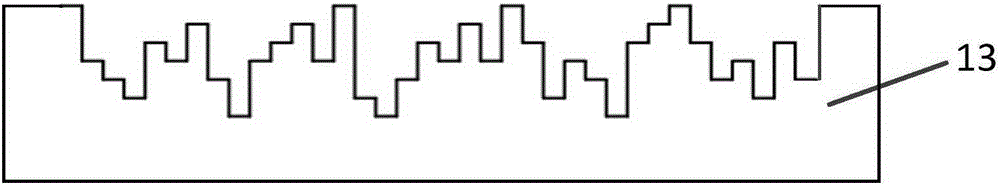

[0033] Such as figure 2 As shown, the laser incident surface 13 also includes several grooves arranged adjacently, and the g...

Embodiment 2

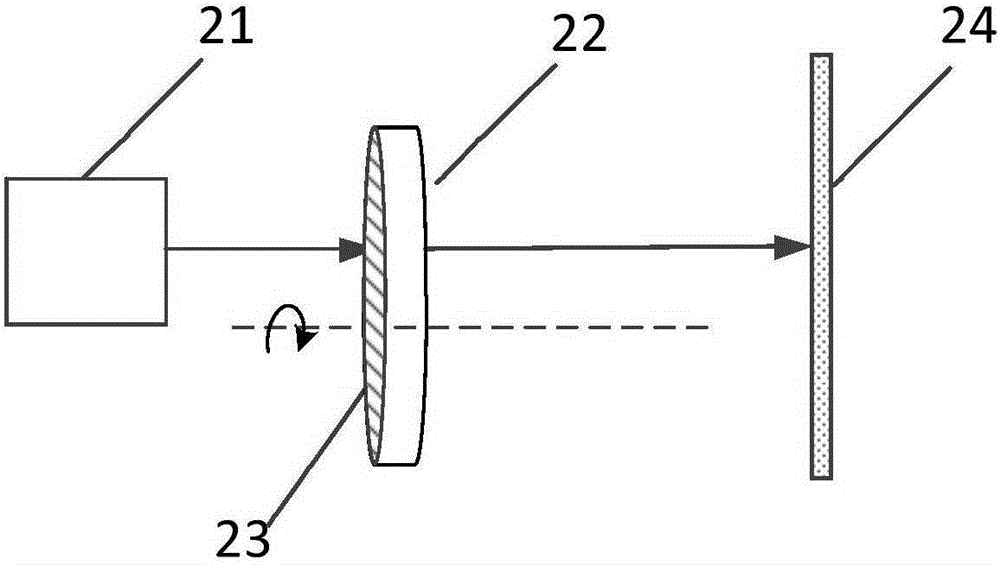

[0036] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the optical element 22 in this solution is a circular sheet structure, wherein the surface of the circular sheet structure is the laser incident surface 23 .

[0037] When performing speckle removal on the laser beam emitted by the laser light source 21, the optical element 22 is preferably rotated at a high speed on a line perpendicular to the laser incident surface 23 under the action of an external force, and the rotation speed is preferably 10000r / min. Wherein, the axis is parallel to the laser beam, so that the optical element 22 is kept perpendicular to the laser beam and rotates at a high speed. The laser beam whose optical path is changed by the optical element 22 is irradiated on the light screen 24. During the integration period of a human eye, the speckle structure will be continuously superimposed to gradually reduce the contrast of the speckle. When the ...

Embodiment 3

[0040] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the optical element 32 in this solution is a tubular structure with a circular cross-section, wherein the inner surface of the tubular structure is the laser incident surface 33 . The laser light source 31 is located inside the tubular structure, and its light emission direction is perpendicular to the axial direction of the tubular structure, so only a part of the optical element 32 is located in the light emission direction of the laser light source 31 .

[0041]When performing speckle removal on the laser beam emitted by the laser light source 31, the optical element 32 rotates at a high speed around the straight line in the axial direction of the tubular structure under the action of an external force, and the rotation speed is preferably 10000r / min. Wherein, the axis is perpendicular to the laser beam, so that the optical element 32 is kept parallel to the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com