Structural shape analysis method for stereovision image distortion calibration of stereo light microscope (SLM)

A distortion correction and image distortion technology, which is applied in the field of structure and shape analysis for SLM microscopic stereoscopic image distortion correction, can solve problems such as difficulty in model use and implementation, unstable calibration results, and inability to meet micro-operations. Improve the technical bottleneck, easy operation, high-precision distortion correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

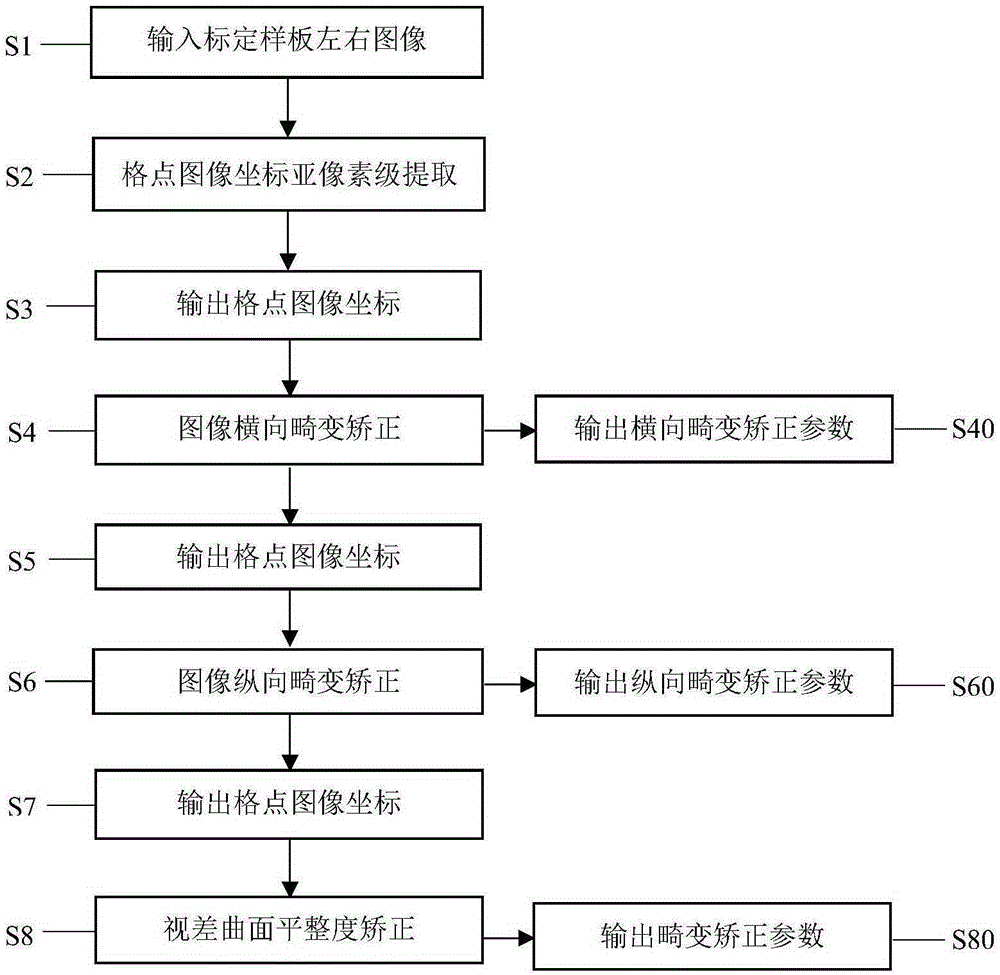

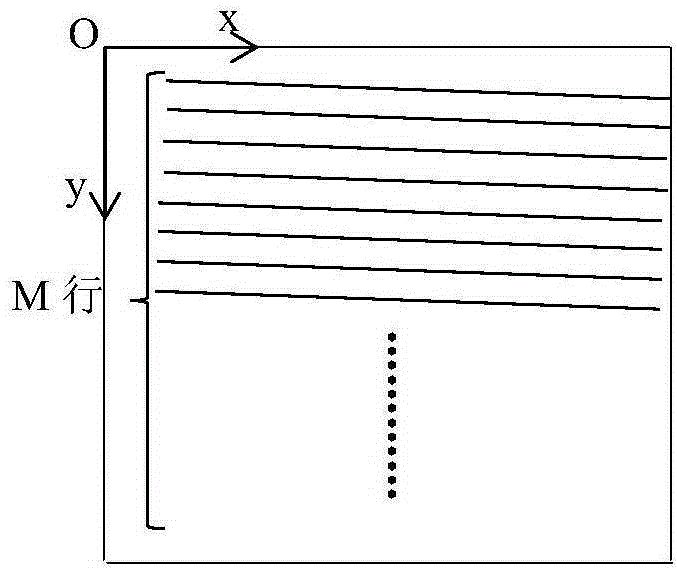

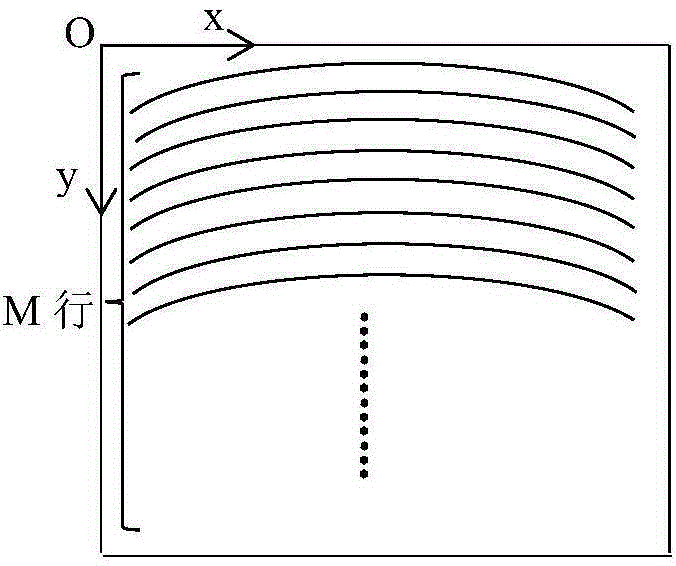

[0047] The present invention is described in further detail now in conjunction with accompanying drawing. figure 1 , Figure 5 , Figure 10 , Figure 13 A flowchart showing the multi-order distortion correction shape analysis method for SLM microscopic stereo vision images involved in the present invention, Figure 2-Figure 4 , Figure 7-Figure 9 , Figure 11 Figure 12 , is the comparison between the distorted image and the ideal image existing in the micro stereo vision system involved in the present invention. The structural shape analysis method for SLM microscopic stereo vision image distortion correction comprises the following steps:

[0048] 1. Input left and right images

[0049] A high-precision grid-like planar calibration template is produced by photolithography. The array unit of the calibration template adopts a circular pattern with a diameter of 0.1mm. The center point of the circular pattern is defined as a grid point, and the circular distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com