a wire connector

A wire splicer and splicing technology, applied in the field of wire splices and load-bearing splicing fittings, can solve the problem of not considering the tension bearing capacity of the terminal clamp, and achieve the effects of simple structure, enhanced friction, and good tension bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

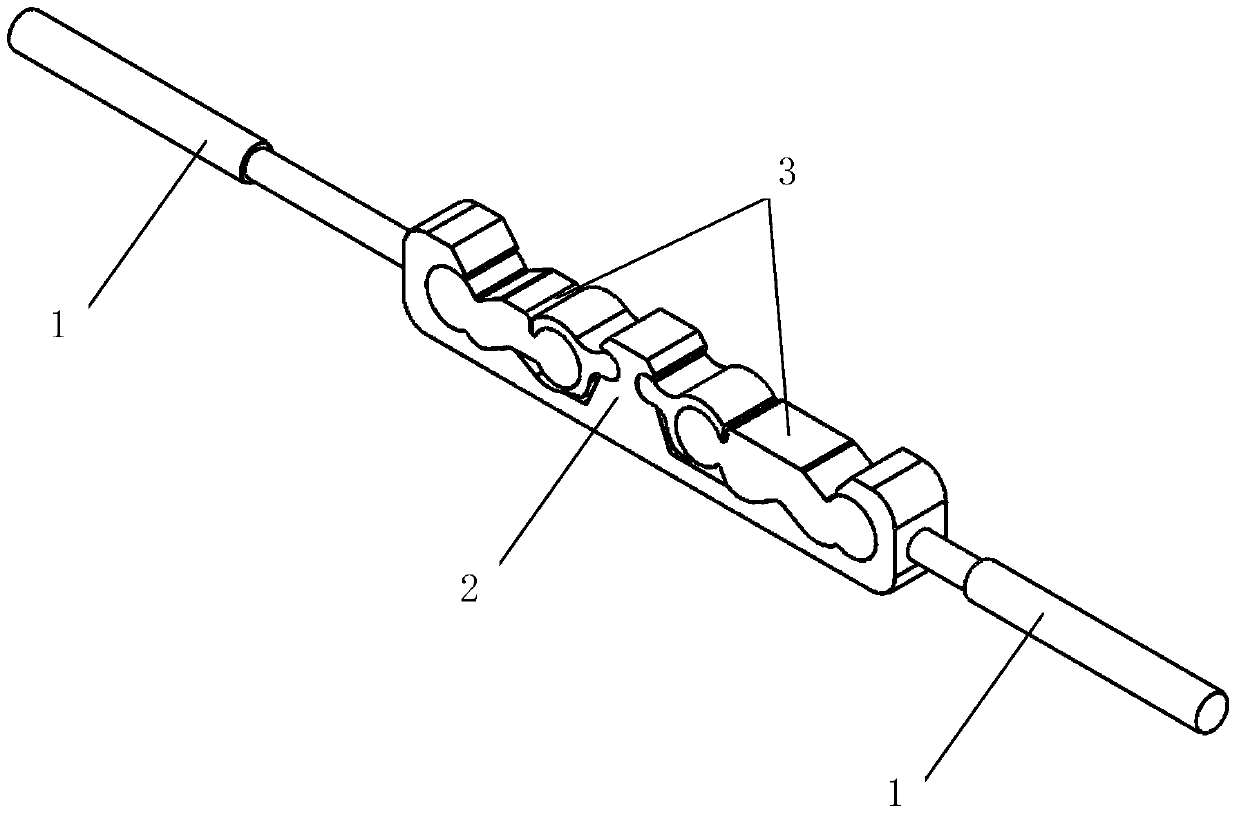

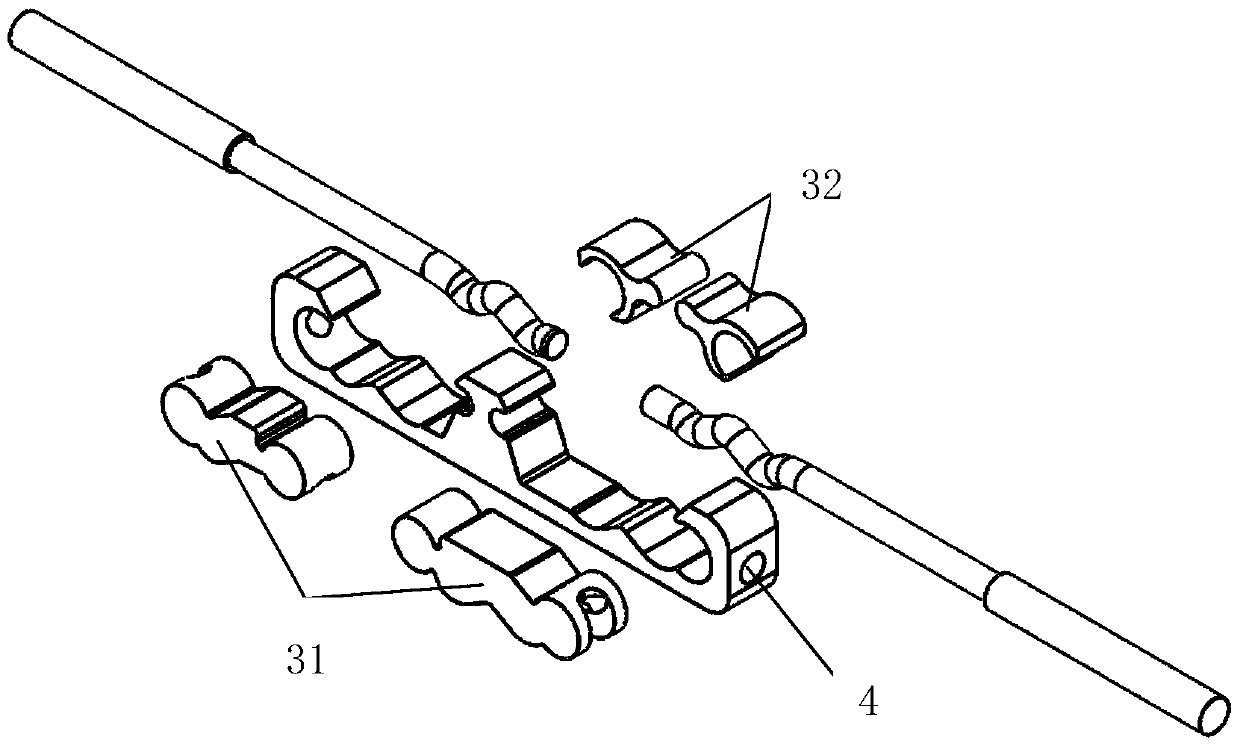

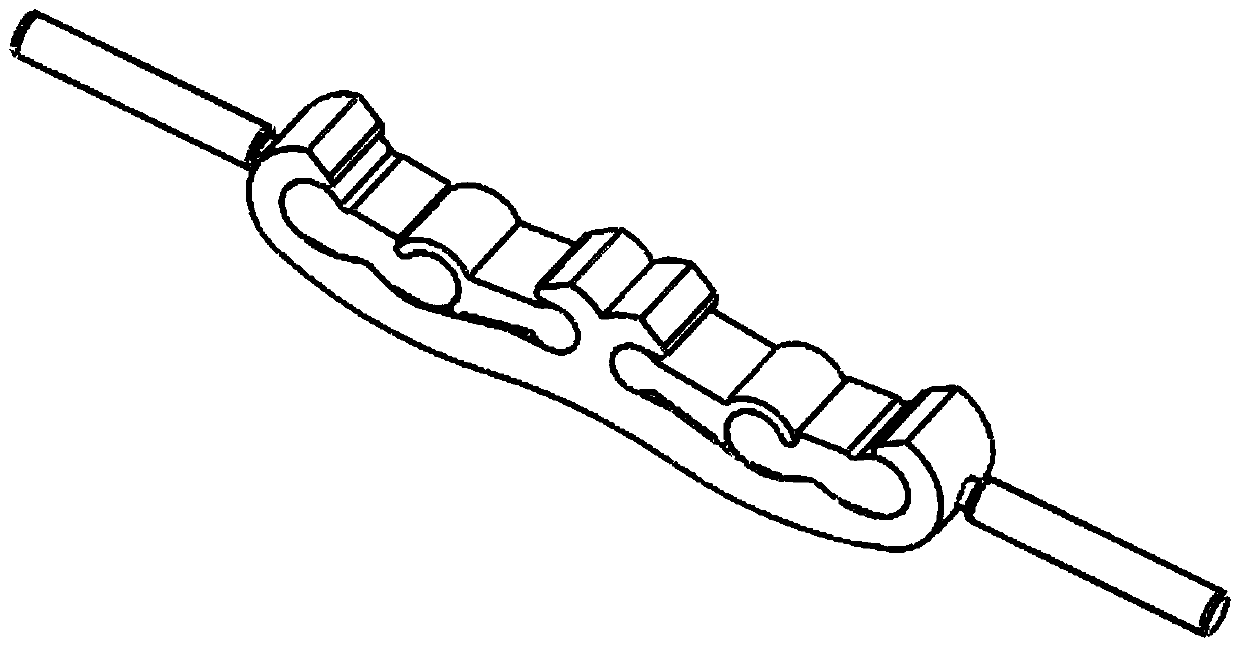

[0047] Such as figure 1 , 2 As shown, a wire connector includes a connector body 2 provided with at least one accommodating cavity 21 and a locking block 3 corresponding to each accommodating cavity, and is used for detachably connecting the connector body 2 and the lock The locking device of tight block 3; as Figure 7 , 8 As shown, the locking block 3 is assembled in its corresponding accommodating cavity 21; one surface of the accommodating cavity 21 is provided with a concave-convex creasing structure, and one surface of the corresponding locking block 3 is provided with The concave-convex crimping structure matched with it, and the two ends of the connector body 2 are provided with a wire hole 4, and the wire hole 4 is connected with the accommodating cavity 21 adjacent to it; when in use, the wire passes through the wire hole 4 Insert, set between the concave-convex crimping structure of the accommodating cavity 21 and the concave-convex crimping structure of the lock...

Embodiment 2

[0060] On the basis of the technical solution of the wire binding clip described in embodiment 1, the following improvements have been further made:

[0061] The accommodating cavity 21 is a "C-shaped" groove, or the body groove is an "O-shaped" groove. The locking device includes a locking screw 5 .

[0062] The accommodating cavity 21 is a "C-shaped" groove, and the connector body 2 and the locking block 3 are respectively provided with a first through hole and a second through hole, and the second through hole is located in one of the On the block or between two blocks, the first through hole and the second through hole are light holes, and the locking screw 5 passes through the first through hole and the second through hole to cooperate with a locking nut , and the detachable connection and locking of the connector body 2 and the locking block 3 can be realized, or one of the first through hole and the second through hole is a light hole, and one through hole can be conne...

Embodiment 3

[0069] On the basis of the technical solution of the wire clamp described in embodiments 1 and 2, the following improvements have been further made:

[0070] Such as Figure 14 As shown, the connector body 2 is provided with two accommodating cavities 21 arranged in series, and the wire holes 4 on both sides of the connector body 2 are located on the same axis; the connection between the two accommodating cavities 21 The connector body 2 is provided with a through hole 22, and the two accommodating cavities 21 and the through hole 22 are connected through another pair of wire holes 4 respectively; when in use, the wires are inserted from the wire holes 4 on both sides of the connector body 2 and run through the entire accommodating cavity twenty one.

[0071] Such as Figure 15 As shown, the through hole 22 is also provided with a crimping screw 23 in the vertical direction; when in use, one end of the two wires is arranged in the through hole 22, and a locking force is appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com