Permanent magnet synchronous motor subsection skewed pole positioning rotor

A technology for permanent magnet synchronous motors and positioning rotors, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve unfavorable mass production, stator skew Difficulty in embedding wires of slot motors, unfavorable manufacturing, transportation and assembly, etc., to achieve the effect of simple positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

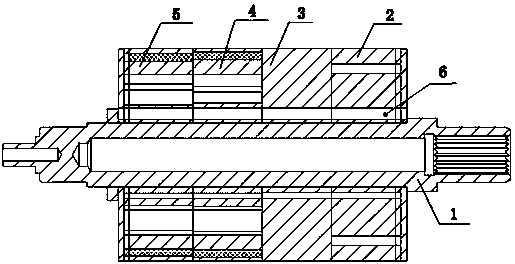

[0026] figure 1 Among them, the present invention includes a rotor shaft (knurled shaft) 1, a rotor core press-fitted on the rotor shaft, and the rotor core is composed of four core segments, namely the first core segment 2, the second core segment 3, The third iron core segment 4, the fourth iron core segment 5, and the positioning through hole 6 after the iron core segments connected in series are rotated.

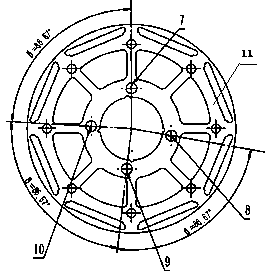

[0027] figure 2 , 3 Among them, punching holes 7, 8, 9, 10 are provided on the rotor punching plate 11, wherein 7 is the positioning base point, and 8, 9, 10 are matching points. The rotor punch 11 is formed by stamping a silicon steel sheet through a die, and the thickness depends on the specification and model, such as 0.35mm, 0.5mm, etc.

[0028] Figure 4 , 5 Among them, the rotor punches 11 are stacked to form hollow rotor segments, and magnetic steel (permanent magnets) 12 are installed in the hollow rotor segment, and the length of each hollow rotor segment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com