A Double Interleaved Hybrid Excitation Motor

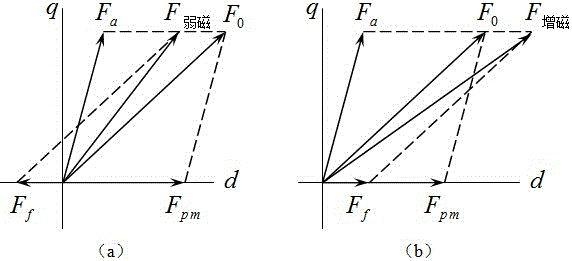

A hybrid excitation motor, AC excitation technology, applied in synchronous motors with static armatures and rotating magnets, etc., can solve the problem of not fully exerting the armature magnetomotive force, etc., and achieve a wide range of constant power speed regulation and magnetic regulation. Good performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

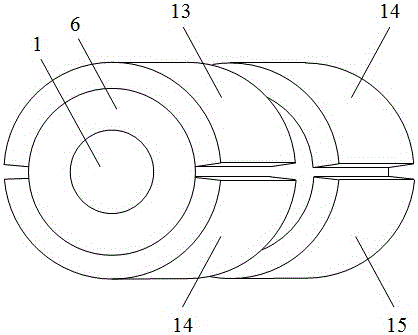

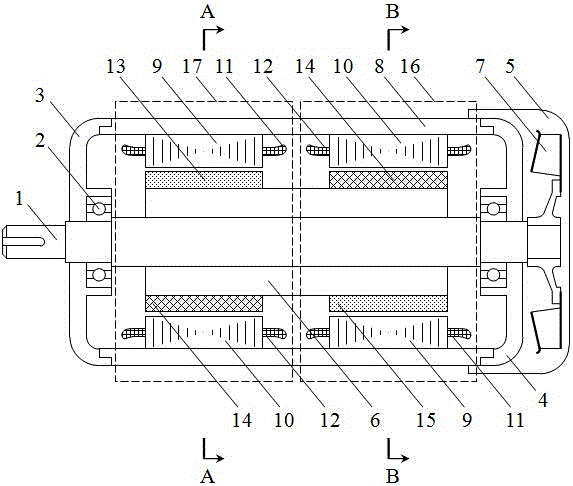

[0029] The present invention will be specifically described below through the accompanying drawings and embodiments.

[0030] A double interleaved hybrid excitation motor such as figure 2 , image 3 and Figure 4 As shown, it includes a front end cover 3, a rear end cover 4 and a casing 8, the casing 8 is arranged between the front end cover 3 and the rear end cover 4, and the casing 8 is made of magnetically conductive material. The front end cover 3 and the rear end cover 4 are provided with a rotating shaft 1 in the middle, and the middle parts of the front end cover 3 and the rear end cover 4 are connected with the rotating shaft 1 through the bearing 2, and the bearing 2 is provided to facilitate the rotating shaft 1 relative to the front end cover 3 and the rear end cover 4. make a turn. The ends of the front end cover 3 and the rear end cover 4 are connected to the casing 8 . A fan 7 is installed at the rear end of the rotating shaft 1 . The fan 7 is symmetrical ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com