Stator partitioned alternating current excitation type hybrid excitation brushless motor based on hybrid pole rotor

A technology of AC excitation and hybrid excitation, applied in the direction of motor, magnetic circuit, electric components, etc., can solve the problems of complex structure and poor adaptability of rotating rectifier, improve the utilization rate and magnetic regulation efficiency, improve space utilization rate and power density Effect

Active Publication Date: 2021-10-08

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The brushless design of the DC excitation hybrid excitation motor usually requires the use of a three-dimensional magnetic circuit or a rotary rectifier, which has a complex structure, and the rotary rectifier has poor adaptability at high speed and high temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0064] Basically the same as embodiment 1, the difference is: as Figure 9 As shown, the permanent magnets in each permanent magnet pole are built-in permanent magnets, and each built-in permanent magnet can be a "one" shape, V shape, W shape, U shape, etc., or a multi-layer hybrid type .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

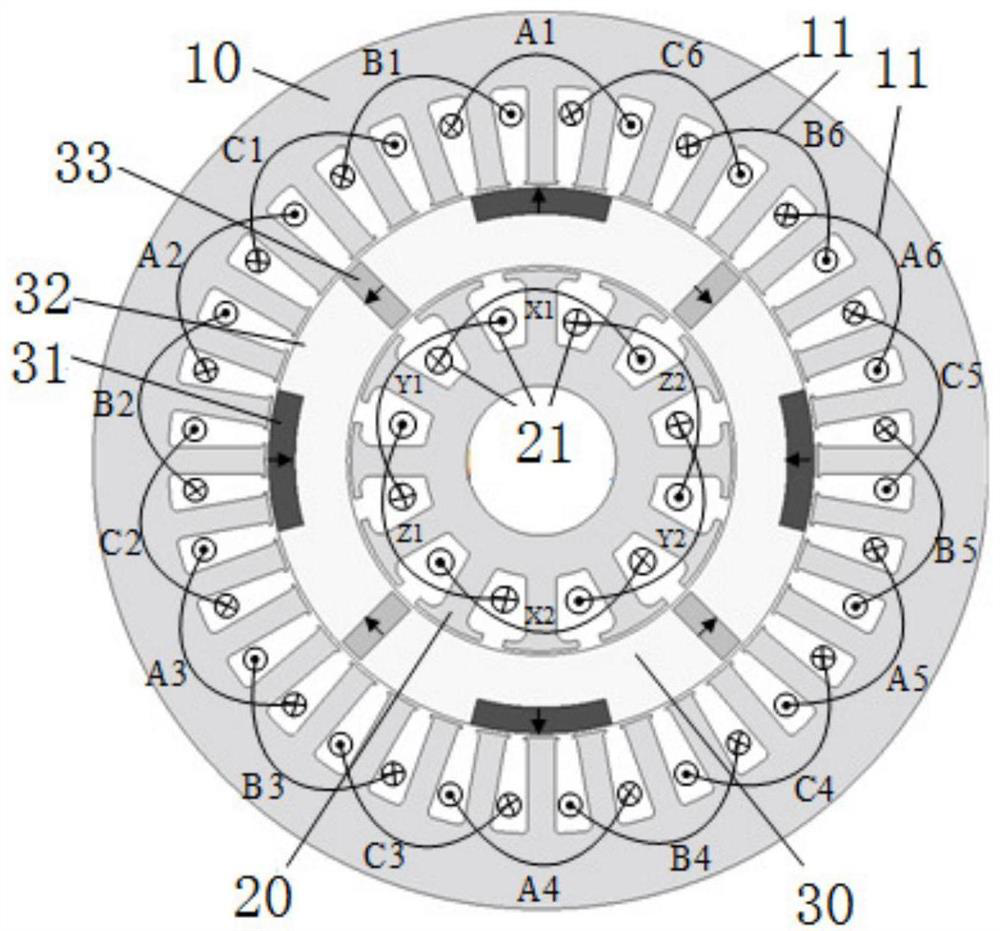

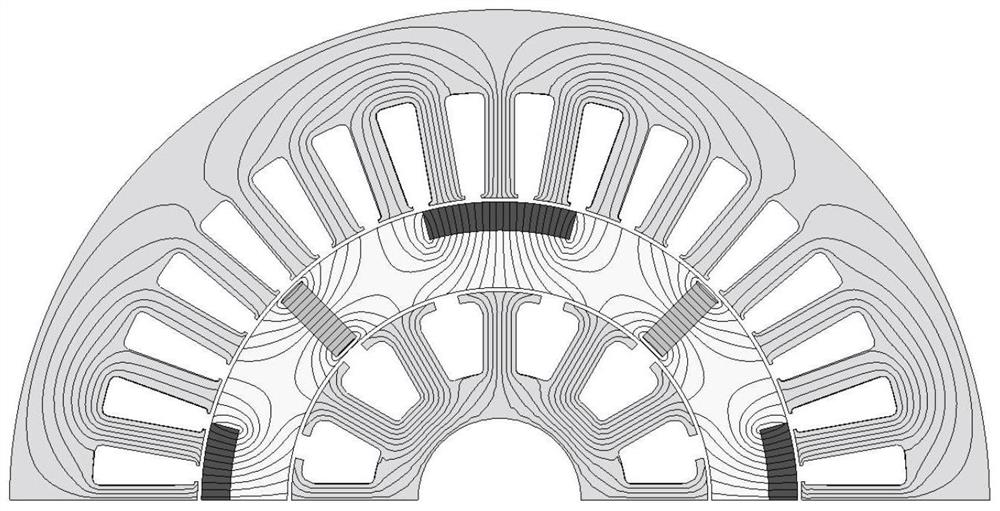

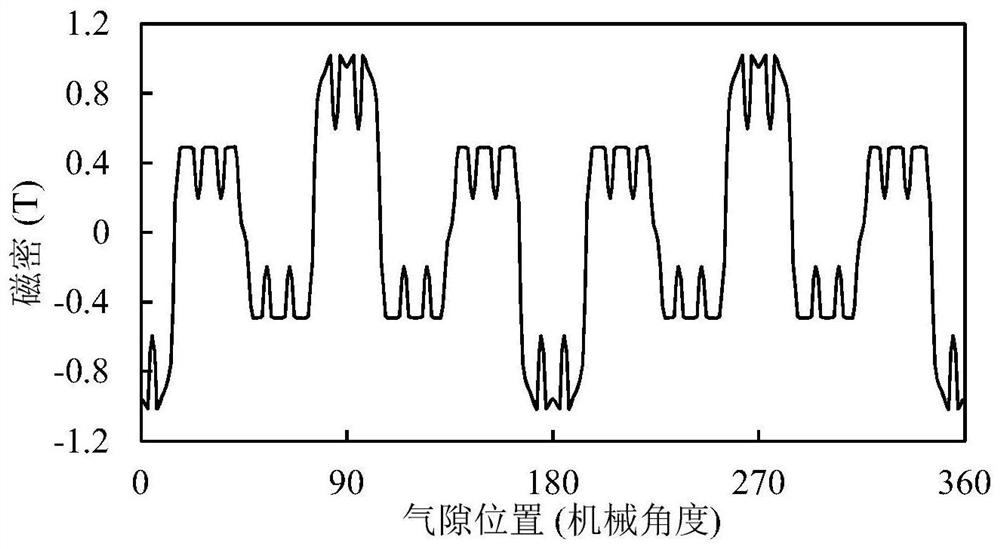

The invention discloses a stator partitioned alternating-current excitation type hybrid excitation brushless motor based on a hybrid pole rotor. The stator partitioned alternating-current excitation type hybrid excitation brushless motor comprises an outer stator, the hybrid pole rotor, an inner stator, an armature winding and an alternating-current excitation winding, the outer stator, the mixed pole rotor and the inner stator are sequentially and coaxially arranged from outside to inside, a main air gap is formed between the mixed pole rotor and the outer stator, and an auxiliary air gap is formed between the mixed pole rotor and the inner stator; the armature winding is wound in a stator slot of the outer stator, and the number of pole pairs of the armature winding is equal to p; the alternating-current excitation winding is wound in a stator slot of the inner stator, the number of pole pairs of the alternating-current excitation winding is equal to i, and p is equal to 3i or p is equal to 5i, wherein i is a positive integer; and the mixed pole rotor can generate p-order harmonic waves and i-order harmonic waves in a main air gap. According to the invention, the space utilization rate and the power density can be effectively improved; the excitation magnetomotive force of each pole acts on a plurality of iron core poles at the same time; and the utilization rate and the magnetic regulation efficiency of the alternating-current excitation winding are effectively improved.

Description

technical field [0001] The invention relates to the field of motor design and manufacture, in particular to a stator partition AC excitation hybrid excitation brushless motor based on a mixed pole rotor. Background technique [0002] Due to the advantages of high torque / power density, high efficiency, and high power factor, permanent magnet motors are not only widely used in industrial fields and home appliances, but also very competitive in electric vehicles, marine propulsion, and aerospace. [0003] However, field weakening of PM motors is achieved by controlling the direct axis current component in the armature winding (- i d ) to achieve, the permanent magnet has the risk of irreversible demagnetization, and the weakening capacity is limited. Moreover, when the permanent magnet motor is applied to power generation occasions such as ships or aviation power sources, a full-power controllable converter is required to realize voltage regulation, which increases the weight...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K16/04H02K1/16H02K1/27

CPCH02K16/04H02K1/16H02K1/2753H02K2201/03H02K2213/03Y02T10/64

Inventor 李健王凯范子涵刘闯

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com