Apparatus and method for combining tobacco sheets

A tobacco sheet and equipment technology, applied in the field of combined tobacco sheets, can solve the problems of reducing production speed and not allowing conventional connection methods, etc., and achieve the effect of strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

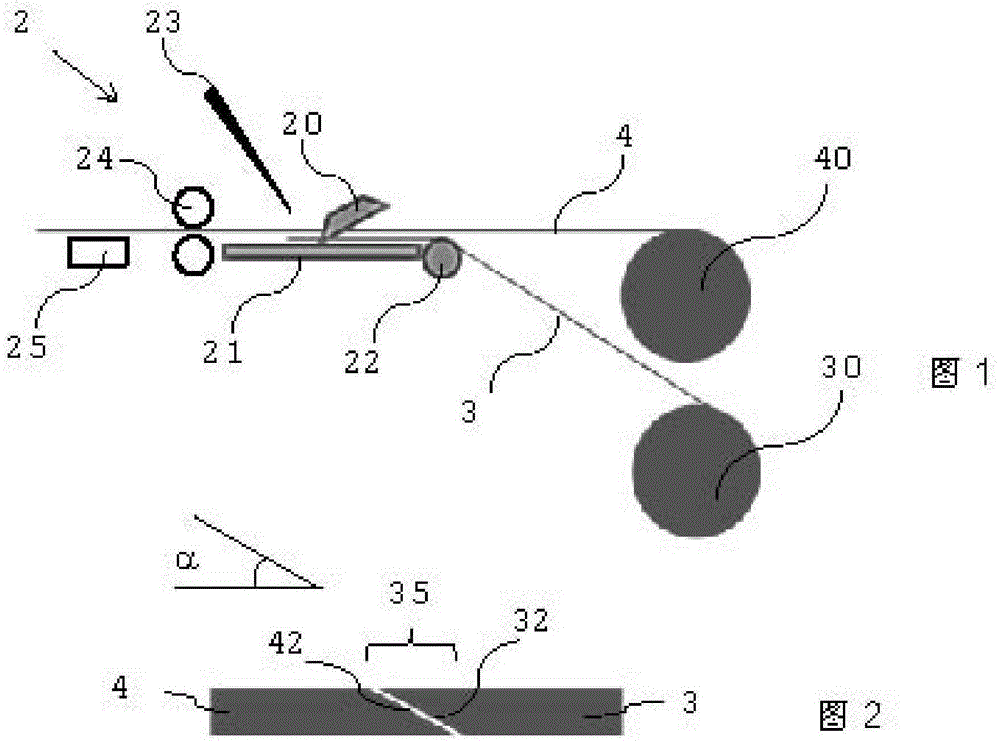

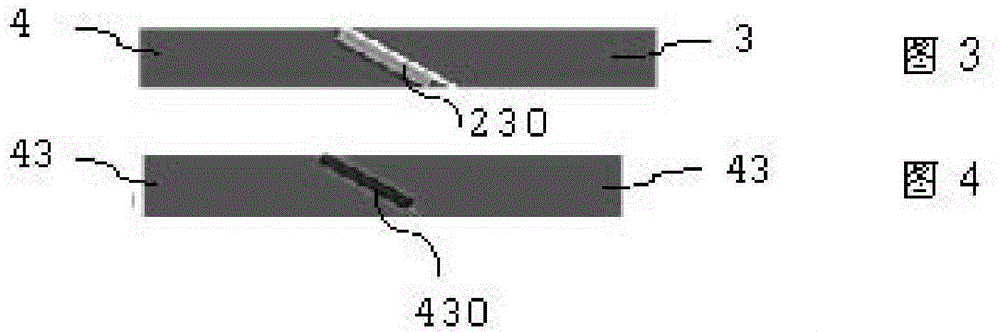

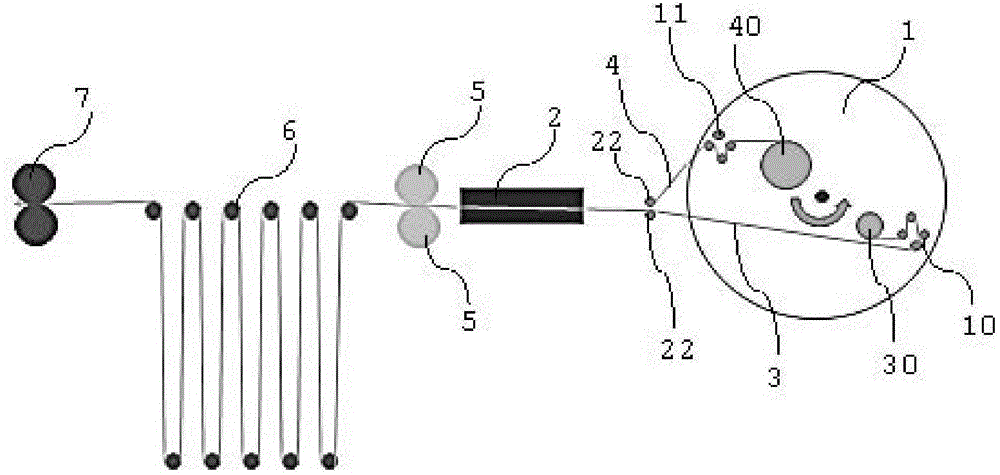

[0042] exist figure 1 , the first and second tobacco sheets 3 , 4 are supplied to the splicing unit 2 from respective bobbins 30 , 40 . A first tobacco sheet 4 is used and passed through the splicing unit 2 in a substantially linear direction. The first tobacco sheet 4 is further conveyed to a tobacco sheet processing unit (not shown) arranged further downstream. Such a processing unit may eg be a crimping unit or a rod forming unit. The tobacco sheet 3 from the second bobbin 30 is guided by guide pulleys 22 and fed to the splicing unit 2 (here from below the tobacco sheet 4 in use) before the end of the tobacco sheet 4 on the bobbin 40 . The two tobacco sheets 3, 4 are arranged on top of each other and aligned on the support surface 21 of the splicing unit. It is then cut off by a cutting knife 20 at a cutting angle α. By cutting, a well-defined tail portion of the first tobacco sheet 3 and a well-defined head portion of the second tobacco sheet 4 are provided. After cut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap