A method of intelligent large-scale seeding, seedling raising and direct seeding planting of leaf vegetables

A technology for sowing seedlings and leafy vegetables, which is applied in the field of intelligent large-scale sowing seedlings and live planting of leafy vegetables, can solve problems such as labor shortages, achieve the effects of solving labor shortages, solving remote management, and realizing intelligent management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

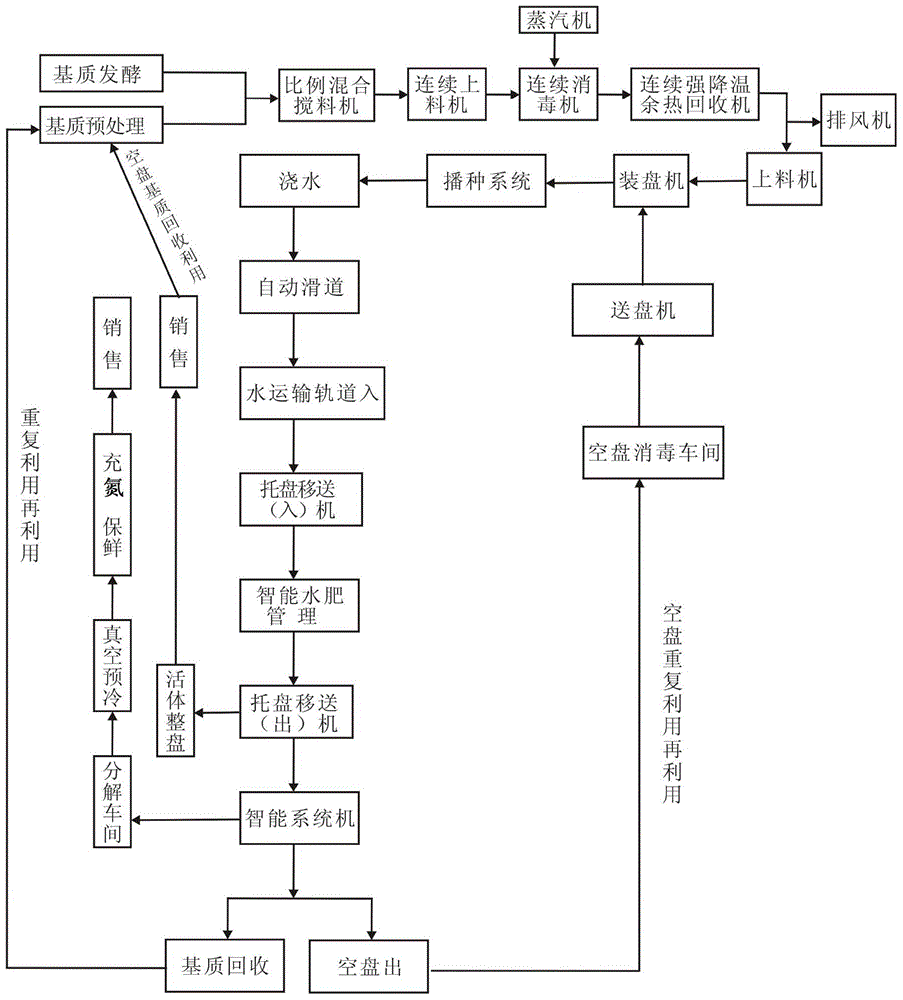

[0033] Such as figure 1 As shown, the method for leafy vegetable intelligent large-scale sowing seedling raising and live planting of the present invention comprises the following steps:

[0034] Step 1. First, different raw materials (as long as they are organic matter) such as cow dung, peat, rice husk, and plant cake fertilizer are fermented and sent to each stacking port of the proportional mixer for work;

[0035] Step 2, when the proportional mixing mixer gets the work order, four (or more) substrates enter the mixing machine at the same time according to the set ratio, mix and send to the continuous feeding machine, and the steam engine also works synchronously;

[0036] Step 3: The continuous feeding machine is equipped with a material sensor. When the material sensor senses the arrival of the matrix and the temperature of the steam engine reaches the set temperature, the steam release valve automatically opens and enters the continuous disinfection cabinet, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com