Shoe outsole and vamp with cattlehide powder and manufacturing method of shoe outsole and vamp

A shoe outsole and shoe upper technology, applied in the field of shoe soles and shoe uppers, can solve problems such as inability to achieve three-dimensional spraying, high cost, and inability to prevent slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

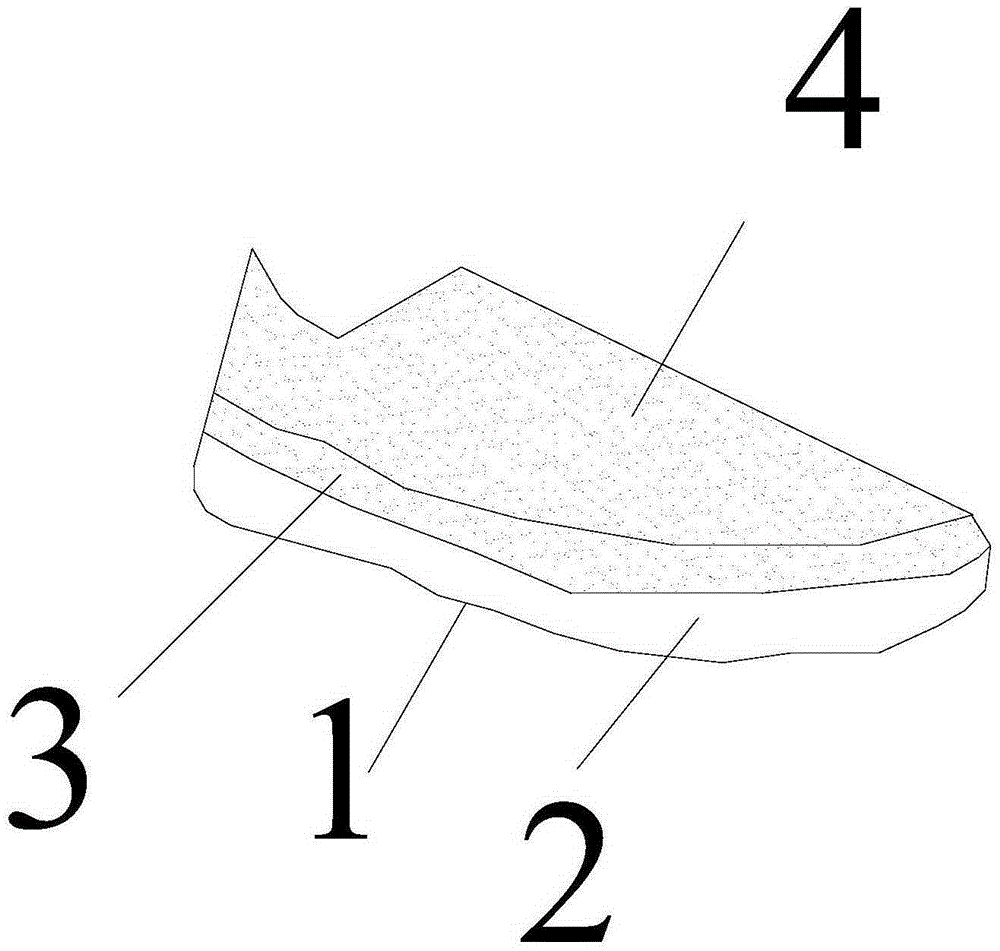

[0025] As attached figure 1 As shown, a shoe outsole and upper with leather powder, comprising a shoe outsole body 1 and an upper body 4, the bottom surface of the shoe outsole body 1 and the face of the upper body 4 are provided with adhesive Layer 2. Cowhide powder 3 is sprayed on the adhesive layer 2.

[0026] Preferably, the outsole body 1 and the upper body 4 are made of PU.

[0027] Preferably, the adhesive layer 2 is a water-based glue, and the model is No. 225 water-based glue, which can be directly purchased from the market.

Embodiment 2

[0029] As attached figure 1 As shown, a shoe outsole and upper with leather powder, comprising a shoe outsole body 1 and an upper body 4, the bottom surface of the shoe outsole body 1 and the face of the upper body 4 are provided with adhesive Layer 2, the adhesive layer 2 is sprayed with imitation leather powder 3.

[0030] Preferably, the outsole body 1 and the upper body 4 are made of EVA.

[0031] Preferably, the adhesive layer 2 is a water-based glue, and the model is No. 225 water-based glue, which can be directly purchased from the market.

Embodiment 3

[0033] As attached figure 1 As shown, a shoe outsole and upper with leather powder, comprising a shoe outsole body 1 and an upper body 4, the bottom surface of the shoe outsole body 1 and the face of the upper body 4 are provided with adhesive Layer 2, the adhesive layer 2 is sprayed with kraft crumbs, leather pulp powder or leather bran powder 3.

[0034] Preferably, the outsole body 1 and the upper body 4 are made of cloth.

[0035] Preferably, the adhesive layer 2 is a water-based glue, and the model is No. 225 water-based glue, which can be directly purchased from the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com