Grinding type juice squeezing mechanism

A technology of rolling type and rolling wheel, which is applied in the field of rolling type juicing mechanism, can solve the problems of short service life, broken teeth of gears, complicated mechanism, etc., and achieve the effect of long service life, low cost and no broken teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

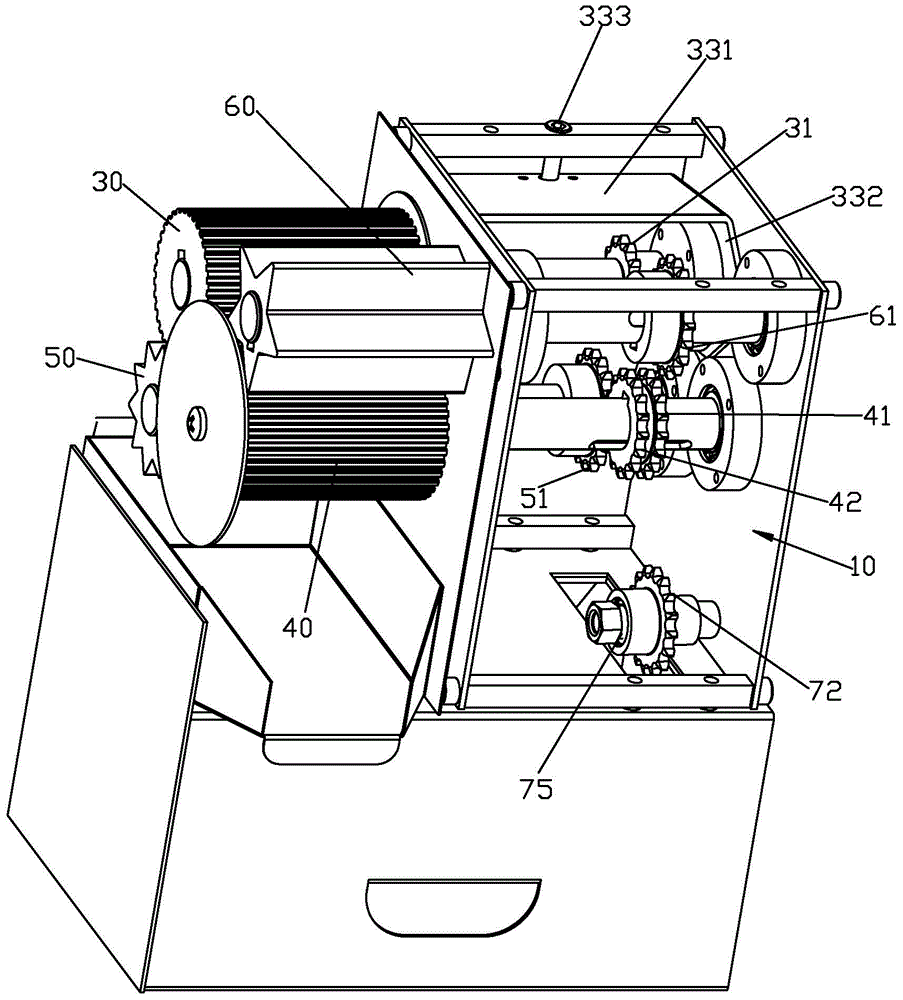

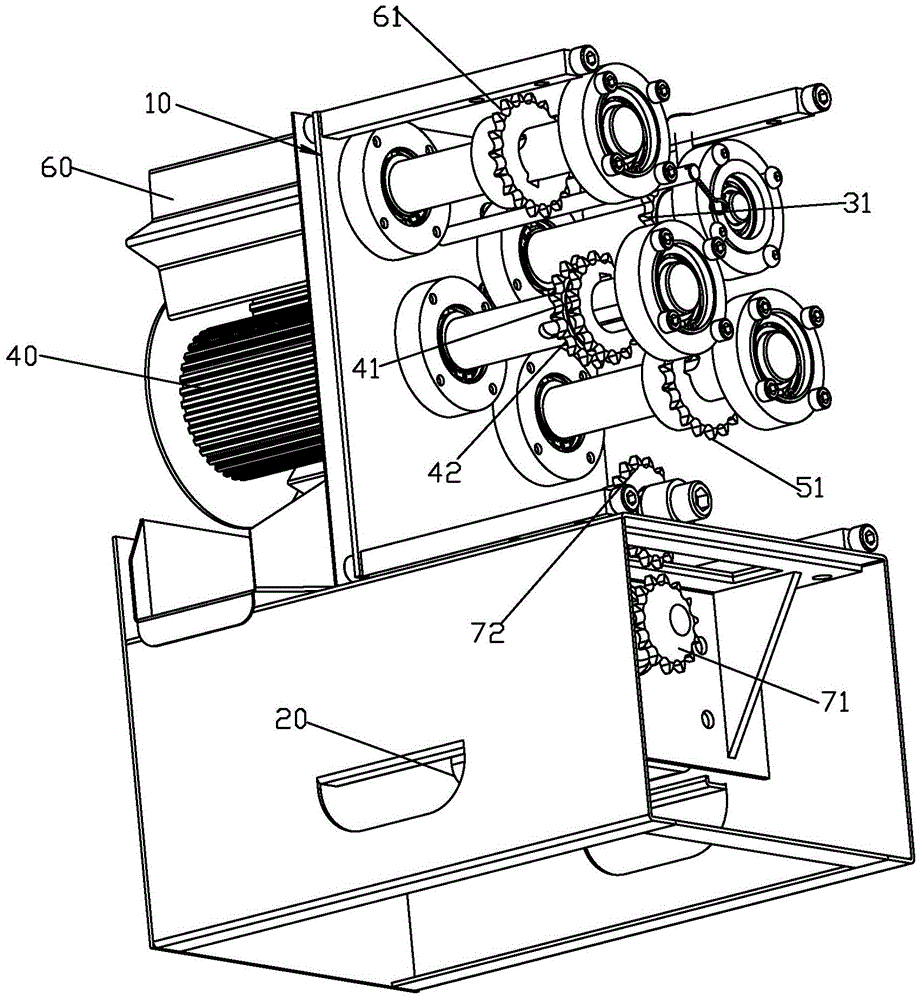

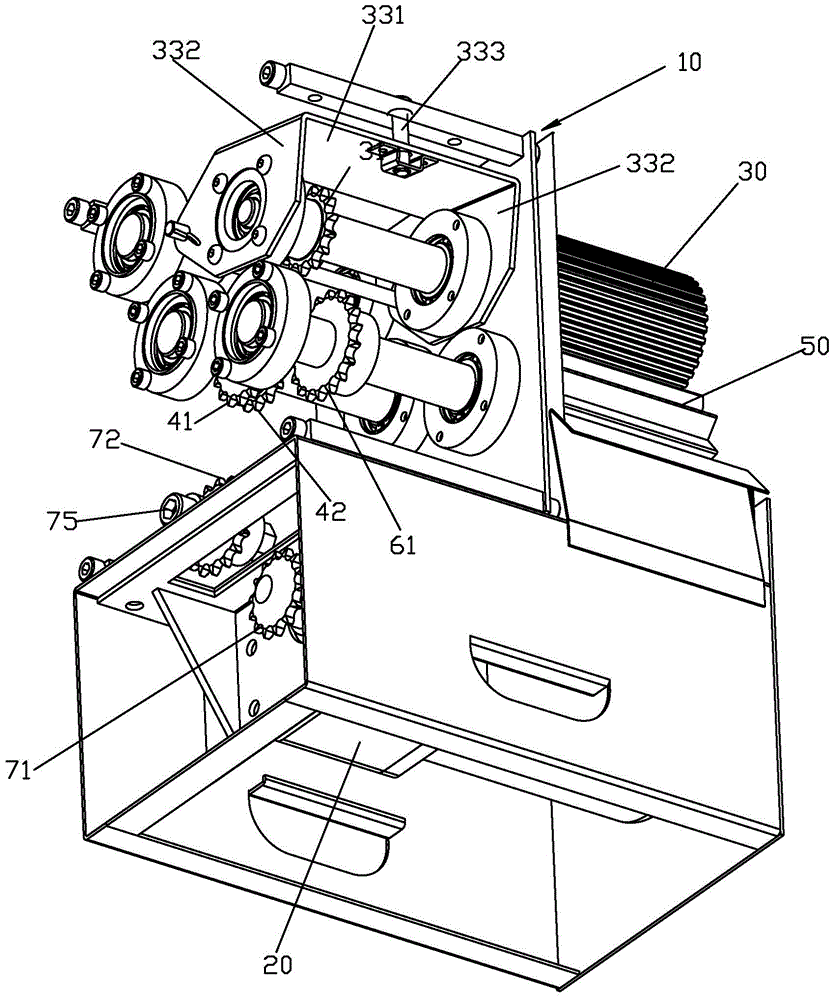

[0028] Please check Figure 1 to Figure 4 , a rolling juice extracting mechanism, including a frame 10, a driving mechanism 20 and a transmission mechanism. The frame 10 is provided with a rotatable upper rolling wheel 30 , a lower rolling wheel 40 , a slag discharge wheel 50 and a feeding wheel 60 . The driving mechanism 20 drives the upper rolling wheel 30 , the lower rolling wheel 40 , the slag discharge wheel 50 and the feeding wheel 60 to rotate through the transmission mechanism, and their rotation axes are arranged horizontally. The upper rolling wheel 30 and the lower rolling wheel 40 are arranged at intervals inclined up and down, the feeding wheel 50 and the slag discharge wheel 60 are arranged at intervals inclined up and down, and the feeding wheel 60 and the slag discharge wheel 50 are respectively located on the upper roller in the projection along the rotation axis. The two sides of the line connecting the axis of the pressing wheel 30 and the axis of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com