Tooth polishing head

A grinding head and tooth technology, applied in the field of tooth grinding grinding head, can solve the problems of high production cost, gum damage, waste of material, etc., achieve the effect of optimizing the grinding structure, good rotatability, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

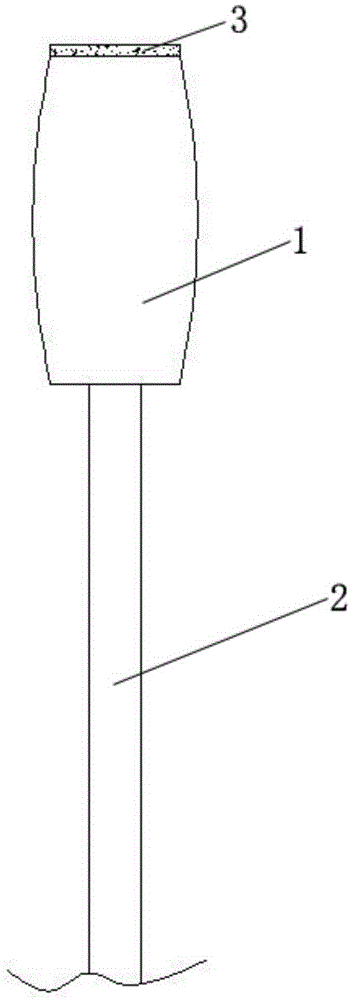

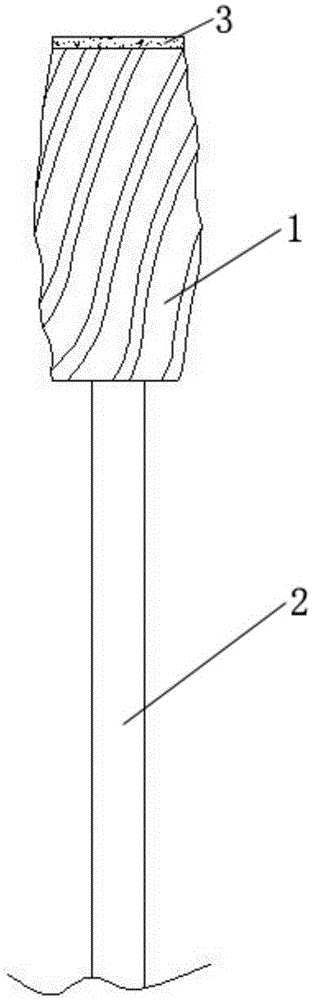

[0016] Such as figure 1 The shown first embodiment of the tooth grinding head of the present invention includes a convex-waisted drum-shaped grinding head 1 and a base rod 2, the fixed end of the grinding head 1 is coaxially affixed to one end of the base rod 2, and the grinding head 1 and the base rod 2 are coaxially fixed. The rod 2 is preferably made of stainless steel, which has low cost and good anti-corrosion performance, and other commonly used metal alloy structures can also be used. The grinding head 1 and the base rod 2 are preferably integrally formed, with high structural strength, good machining processability, and easy to maintain good coaxiality. A grinding layer 3 is provided on the end surface of the grinding end of the grinding head 1. Since the grinding layer 3 is limited on the end surface, when the patient's teeth are ground and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com