Boiler fume denitration and desulfuration dedusting device and process

A technology for boiler flue gas, desulfurization and dust removal, which is applied in the direction of air quality improvement, the use of liquid separation agents, and the separation of dispersed particles. Problems, the effect of stabilizing emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

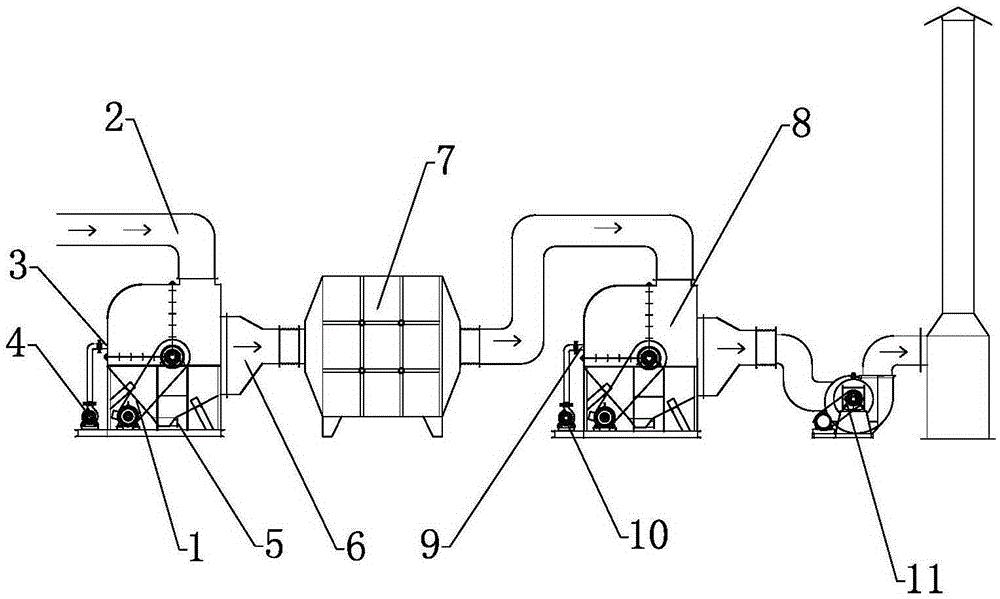

[0017] In order to clearly illustrate the technical characteristics of this solution, the following describes the present invention in detail through specific implementations and in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, a boiler flue gas denitration, desulfurization and dust removal device includes No. 1 supergravity rotating bed pollution control device 1, and No. 1 supergravity rotating bed pollution control device air inlet 2 is connected to the boiler flue gas outlet through a pipe, The alkaline absorption liquid inlet 3 of the gravity rotating bed pollution control device 1 is connected to the alkaline absorption liquid circulating pool through the No. 1 circulating water pump 4, and the sewage outlet 5 of the No. 1 high gravity rotating bed pollution control device is connected to the alkaline absorption liquid circulating pool The air outlet 6 of the No. 1 high-gravity rotating bed pollution control device is connected to the air i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap