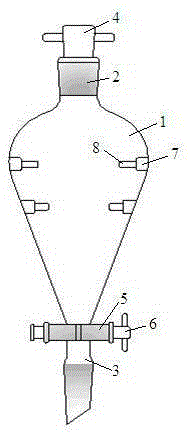

Separating funnel used in extraction process

A separatory funnel and extraction technology, which is applied in the direction of funnels, laboratory containers, liquid solution solvent extraction, etc., can solve the problems of strong dependence on auxiliary facilities, failure to eliminate the emulsified foam function, and low extraction efficiency. The flow rate of the liquid funnel is not smooth, the effect of reducing emulsification and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. A separatory funnel used in the extraction process, comprising a bottle body 1, a bottle mouth 2 arranged on the top of the bottle body 1 and a liquid outlet pipe 3 arranged at the bottom of the bottle body 1, a bottle stopper 4 is installed on the bottle mouth 2, The outlet pipe 3 is provided with a cock cavity 5, and the cock cavity 5 is equipped with a polytetrafluoroethylene cock 6, and the inside of the bottle body 1 is 2 / 5 from the bottom end of the bottle mouth 2 and 1 / 2 from the bottom end of the bottle mouth 2 A plurality of glass bases 7 are evenly distributed at each place, and a hollow demulsification rod 8 with holes is arranged in the glass bases 7. The number of the upper and lower layers of glass bases 7 inside the bottle body 1 is three, and The upper and lower layers of glass bases 7 are distributed alternately. The length of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com