A fully automatic production line for screw oiling and its process

A production line, fully automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems such as the inability to meet the production needs of the enterprise, the low efficiency of screw oiling, the occupation of workers' working hours, etc. The high degree of automation and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

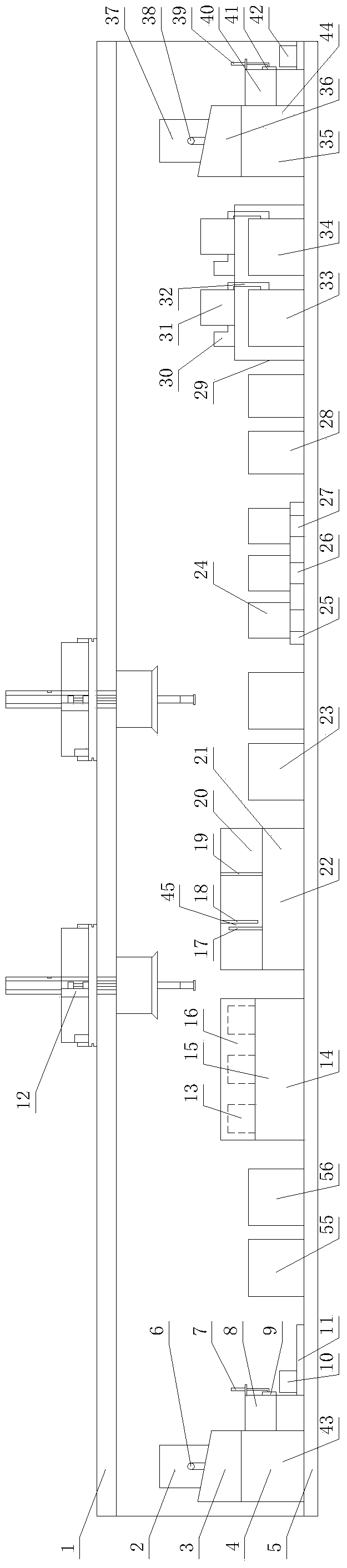

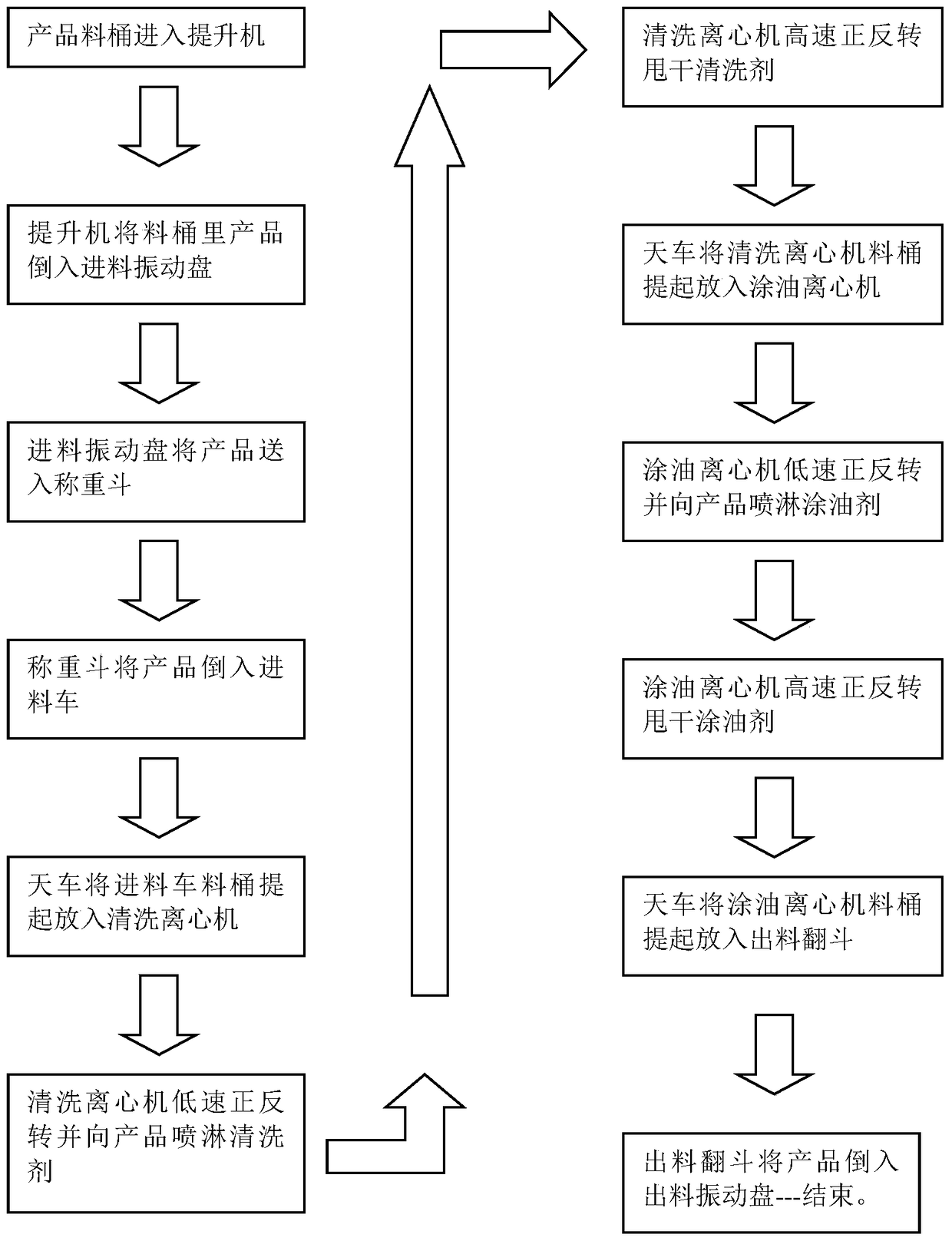

Embodiment 1

[0039] Such as image 3 As shown, the screw to be oiled is put into the feeding dump 2, and the screw is poured into the feeding vibration plate 3 through the rotation of the tipping bucket support frame 6, and the feeding vibration plate 3 sends the screw into the feeding weighing bucket 8 , the cylinder 7 runs and drives the feed baffle 9 to rise upwards, so that the screw is sent into the material barrel 10, and the manipulator 12 lifts the material barrel 10 and sends it into the cleaning centrifuge 55. The cleaning centrifuge 55 first rotates forward and reverse at a low speed Spray the cleaning agent to the screws in the material barrel 10, then clean the centrifuge 55 forward and reverse at a high speed so that the screws in the material barrel 10 dry the cleaning agent to complete the process of cleaning the centrifuge 55, then hand in hand 12 to lift the material barrel 10 and Put it into the oil-coated centrifuge 56, the oil-coated centrifuge 56 first rotates forward...

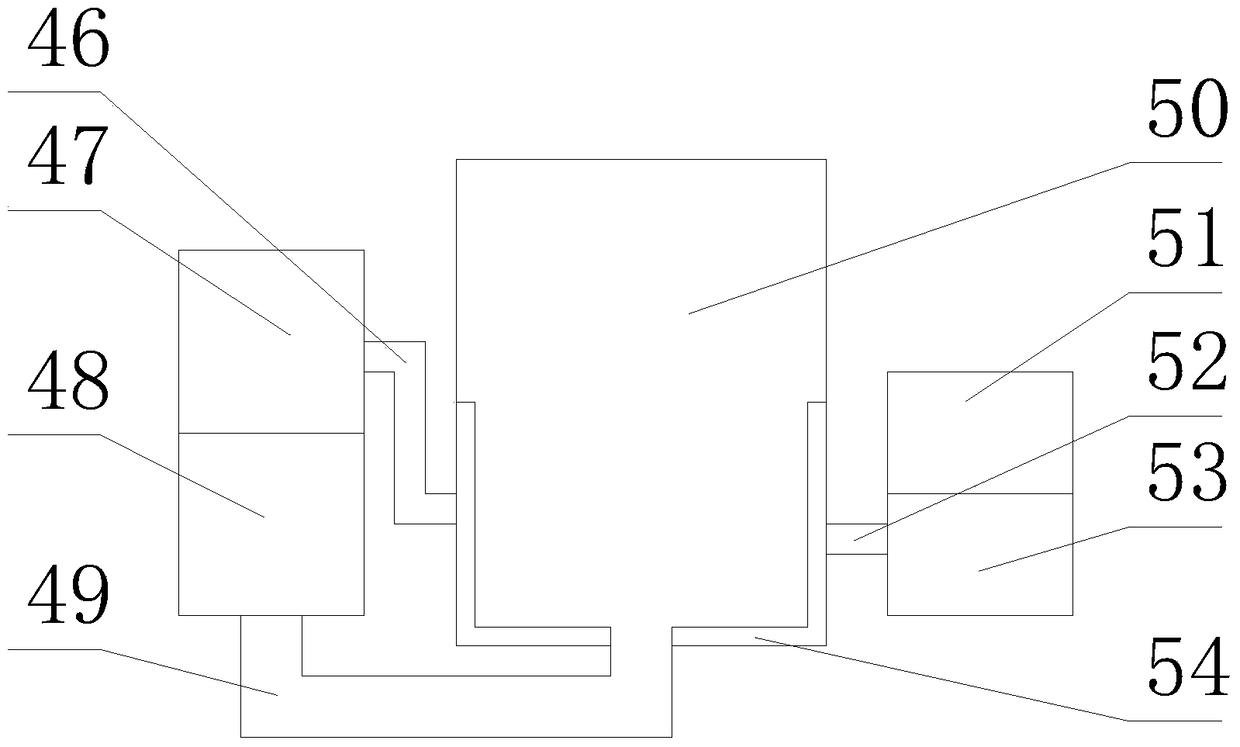

Embodiment 2

[0041] Such as Figure 4 As shown, the screw to be oiled is put into the feeding dump 2, and the screw is poured into the feeding vibration plate 3 through the rotation of the tipping bucket support frame 6, and the feeding vibration plate 3 sends the screw into the feeding weighing bucket 8 , the cylinder 7 runs and drives the feed baffle 9 to rise up, so that the screw is sent into the material barrel 10, and the manipulator 12 grabs the material barrel 10 and puts it into the degreasing device 14 for degreasing. After the degreasing is completed, the manipulator 12 grabs the material barrel 10 into the washing device 22, in the washing device 22, three washing tanks are separated by the first baffle plate 17, the second baffle plate 18, the third baffle plate 19 and the side wall of the water washing device 22, and are respectively filled with cold water. , cold water and hot water, wherein a gap overflow 45 is provided between the first baffle plate 17 and the second baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com