Sand cleaning equipment used for removing heavy casting sand core

A technology for large-scale castings and sand cores, applied in the field of casting process equipment, can solve problems such as low production efficiency, harsh working environment, and products are not easy to move, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

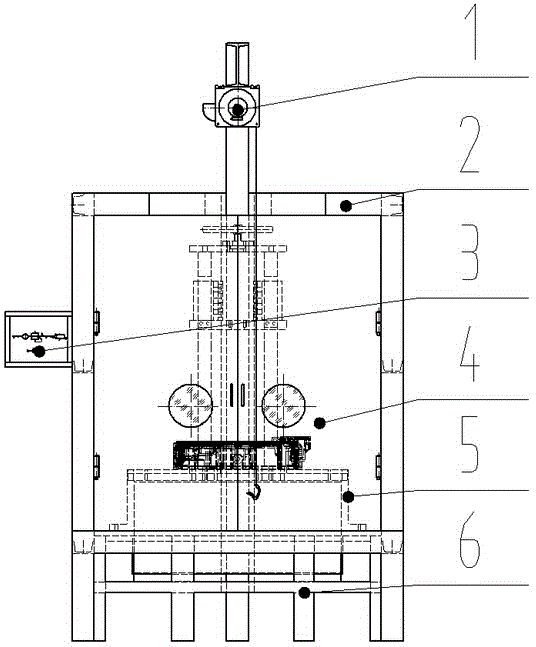

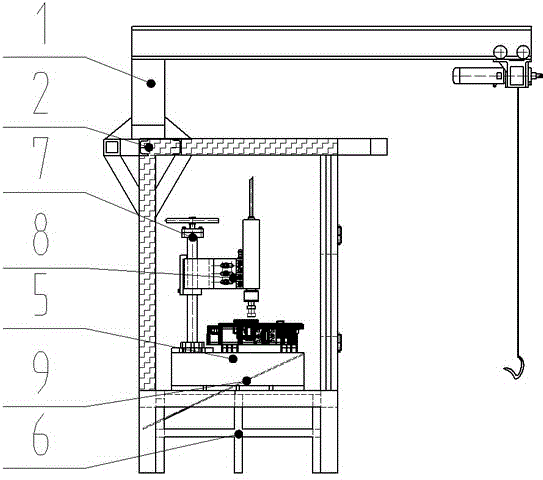

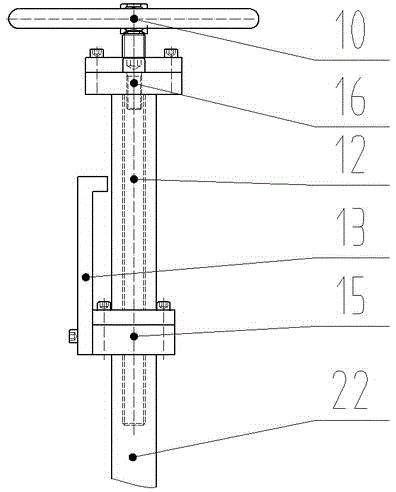

[0022] figure 1 , 2 Among them, the present invention includes a base 6, an air hammer mechanism 8, an air hammer elevating mechanism 7, an elevator 1, a sound-absorbing chamber 2, an air control device 3, and a workbench 5 mounted on the base 6; the height of the base 6 is 500 mm, which is convenient for workers to Operation, use sound-absorbing cotton on the base plate to reduce the noise during work. There is a sand outlet at the bottom of the workbench 5, and a slope sand outlet is opened on the base, which connects with the slope of the workbench so that it can vibrate when working. The sand can slip to the outside. There are two air hammer mechanisms 8 standing on one side of the workbench 5. The air hammer lifting mechanism 7 is connected to the air hammer mechanism 8. The sound-absorbing chamber 2 surrounds the air-hammer mechanism and the product in a relatively closed space. The sound-absorbing chamber is made of sound-absorbing cotton It is welded together with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com