Automatic tire transfer system

An automatic transfer and tire technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of heavy, light, tens of kilograms, heavy, hundreds of kilograms, and only one or two can be handled at a time Problems such as low efficiency of tires and transfer tires, etc., to achieve the effect of not easy to loosen, stable clamping, and stable installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

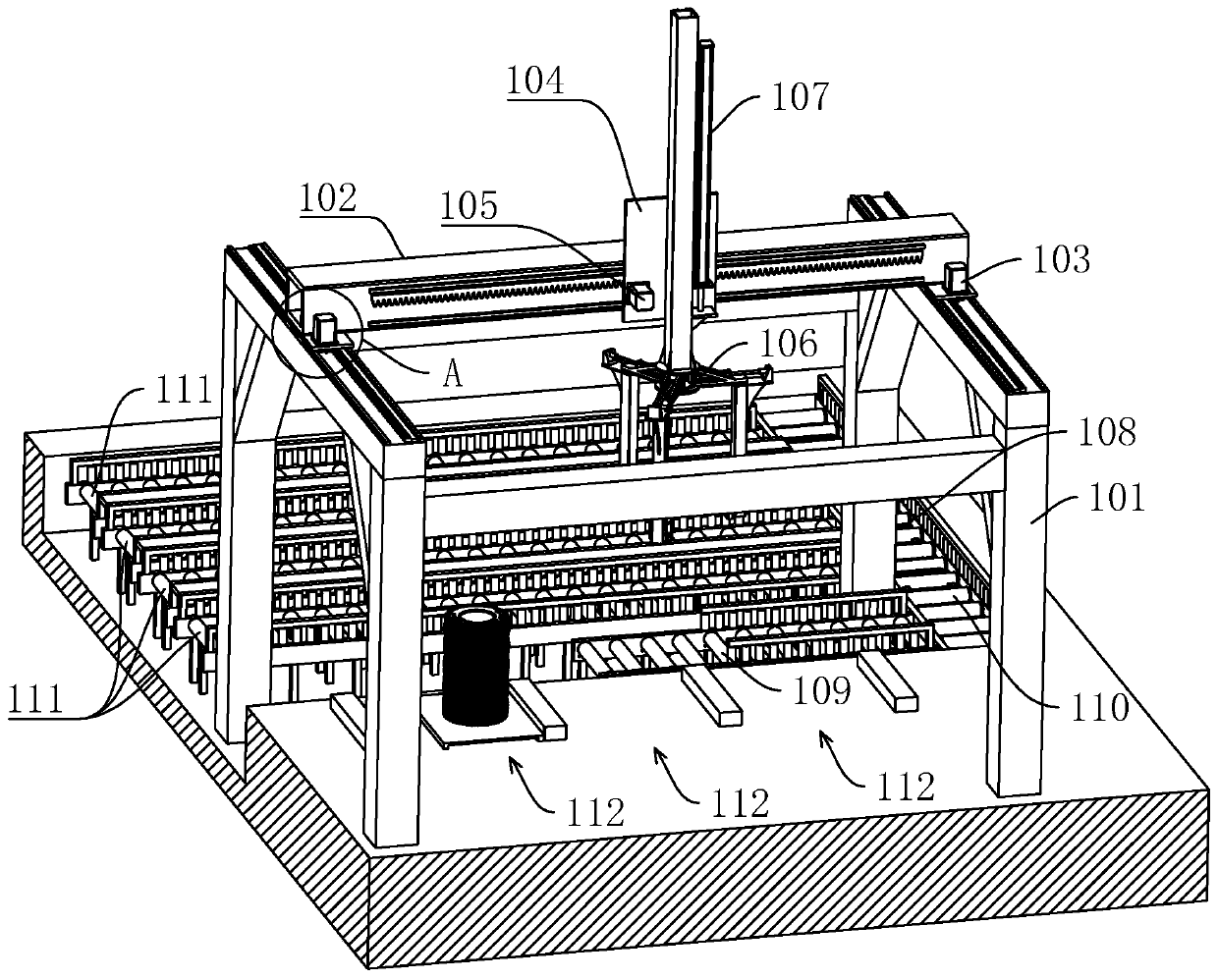

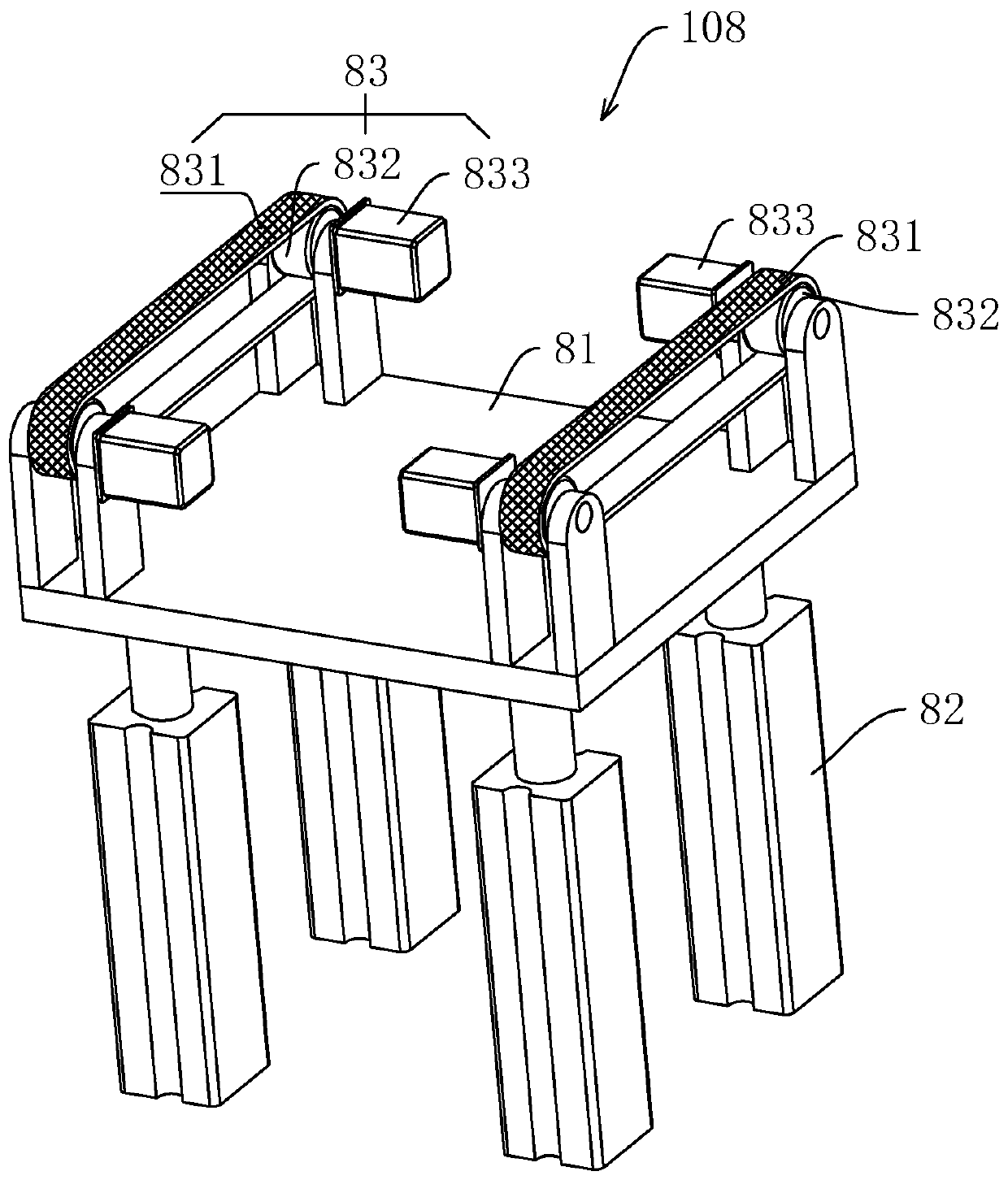

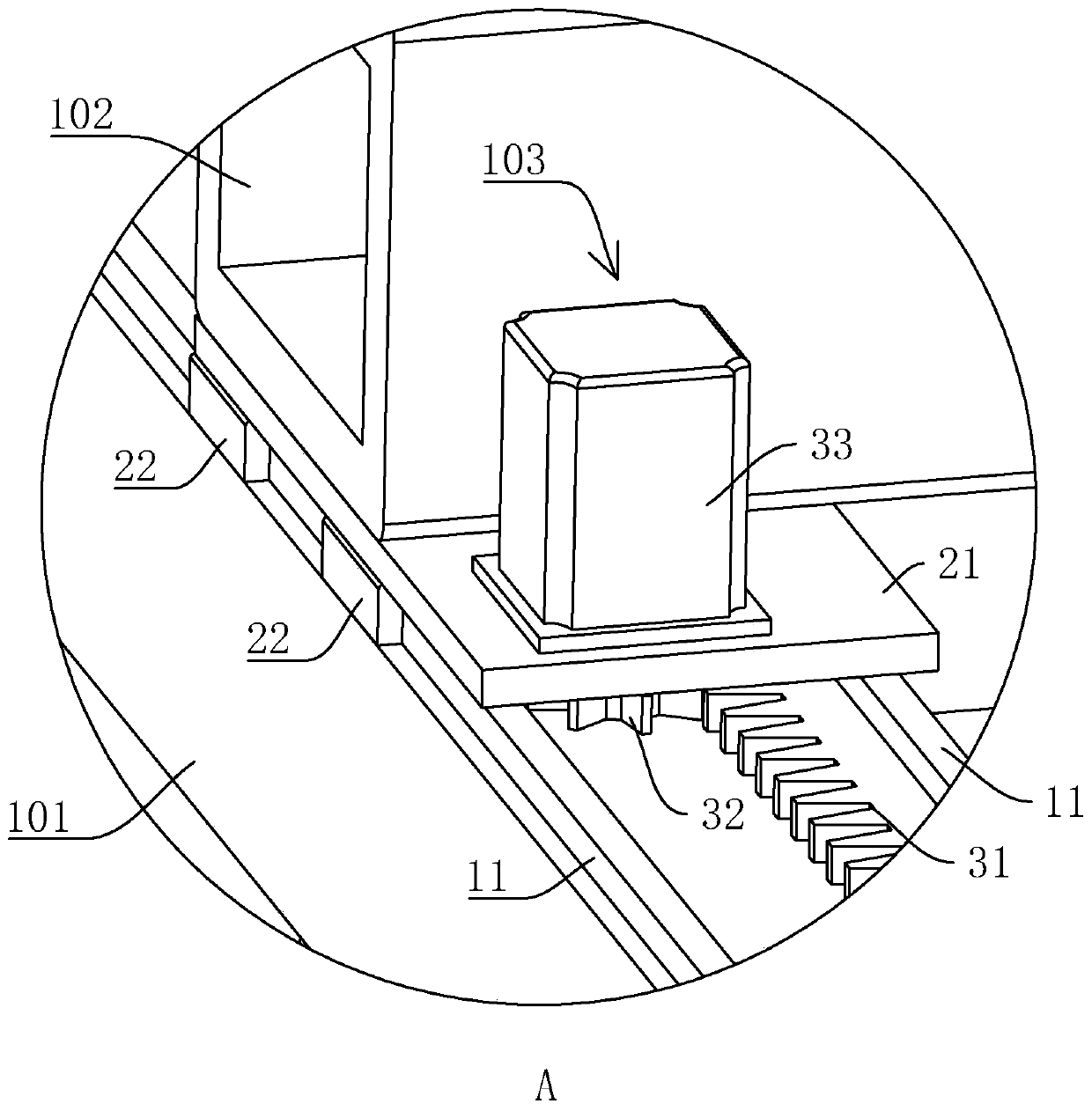

[0041] refer to figure 1 , is an automatic tire transfer system disclosed in the present invention, comprising: incoming rail 109, longitudinal rail 110, horizontal rail 111, gantry frame 101, beam 102, longitudinal driving member 103, first slide plate 104, horizontal driving member 105, mechanical Clamp arm 106 , vertical drive member 107 and transfer assembly 108 . First dig a pit on the surface of a foundation, and then place the incoming rail 109, the longitudinal rail 110, and the horizontal rail 111 in the pit to ensure that the conveying surface of the incoming rail 109, the vertical rail 110, and the horizontal rail 111 are basically level with the foundation surface, and the gantry The frame 101 is fixed by four columns and a plurality of beams, and the columns and beams are all made of square steel pipes.

[0042] The horizontal rails 111 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com