Device for eliminating influence of continuous high-intensity magnetic field on welding operation

A strong magnetic field and continuous technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve problems such as inability to perform normal welding, impact on unit welding quality, restricting engineering progress, etc., to achieve good application value and promotion value, Good degaussing effect, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

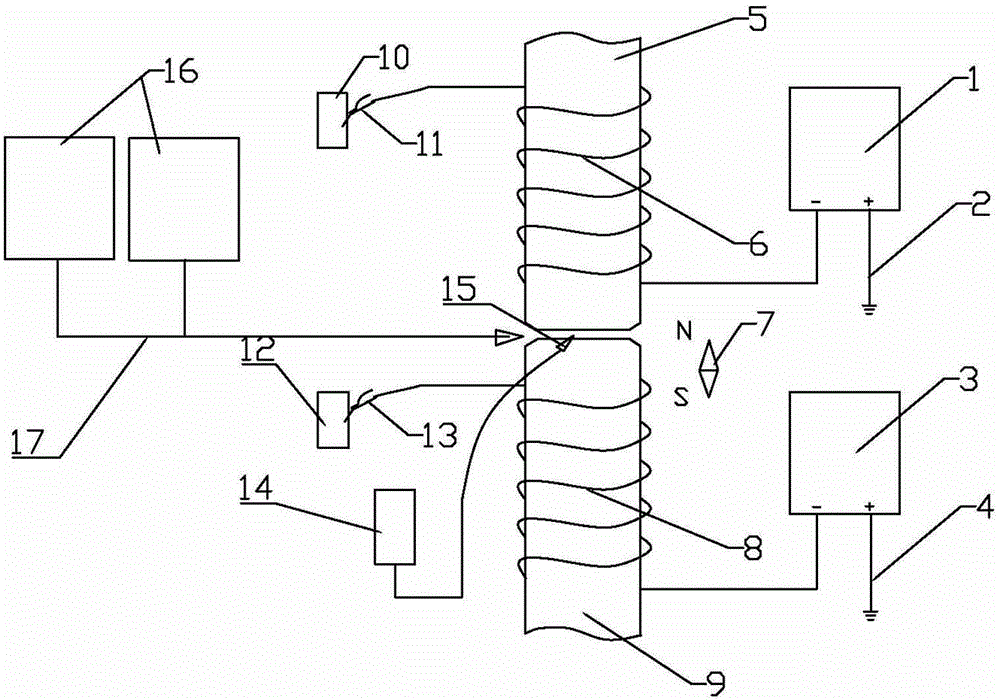

[0017] Such as figure 1 As shown, this device for eliminating the influence of continuous strong magnetic field on welding operation includes an upper electromagnetic induction device and a lower electromagnetic induction device; the upper electromagnetic induction device includes an upper inverter welding machine 1, and the upper inverter The positive pole of the welding machine 1 is reliably grounded through the upper welding ground wire 2, and the negative pole is connected to the upper flexible induction coil 6 wound with several turns on the magnetic upper part 5 to be welded. The coil head of the upper flexible induction coil 6 is connected to the The upper welding tongs 11 are connected, and the upper welding tongs 11 are used to weld the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com