Method and device for controlling prestressed deformation of aluminum thin-walled hull vertical weld

A deformation control and force application device technology, applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of reduced production efficiency, difficult correction, deformation, etc., and achieve the effects of improving production efficiency, good control, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

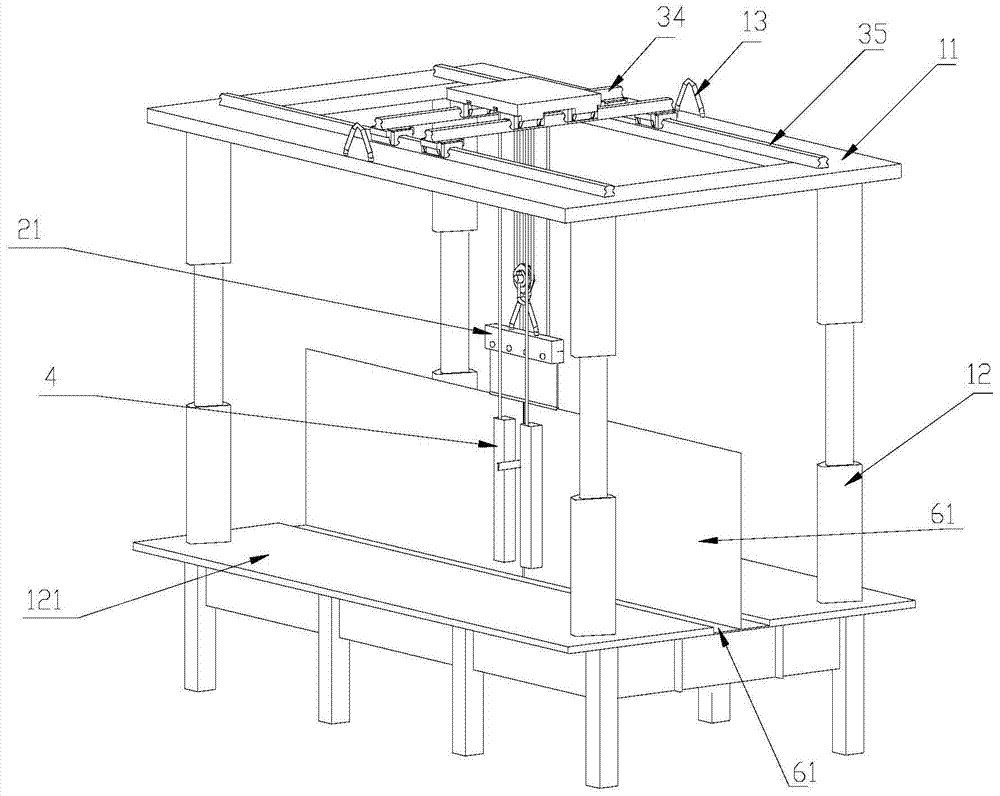

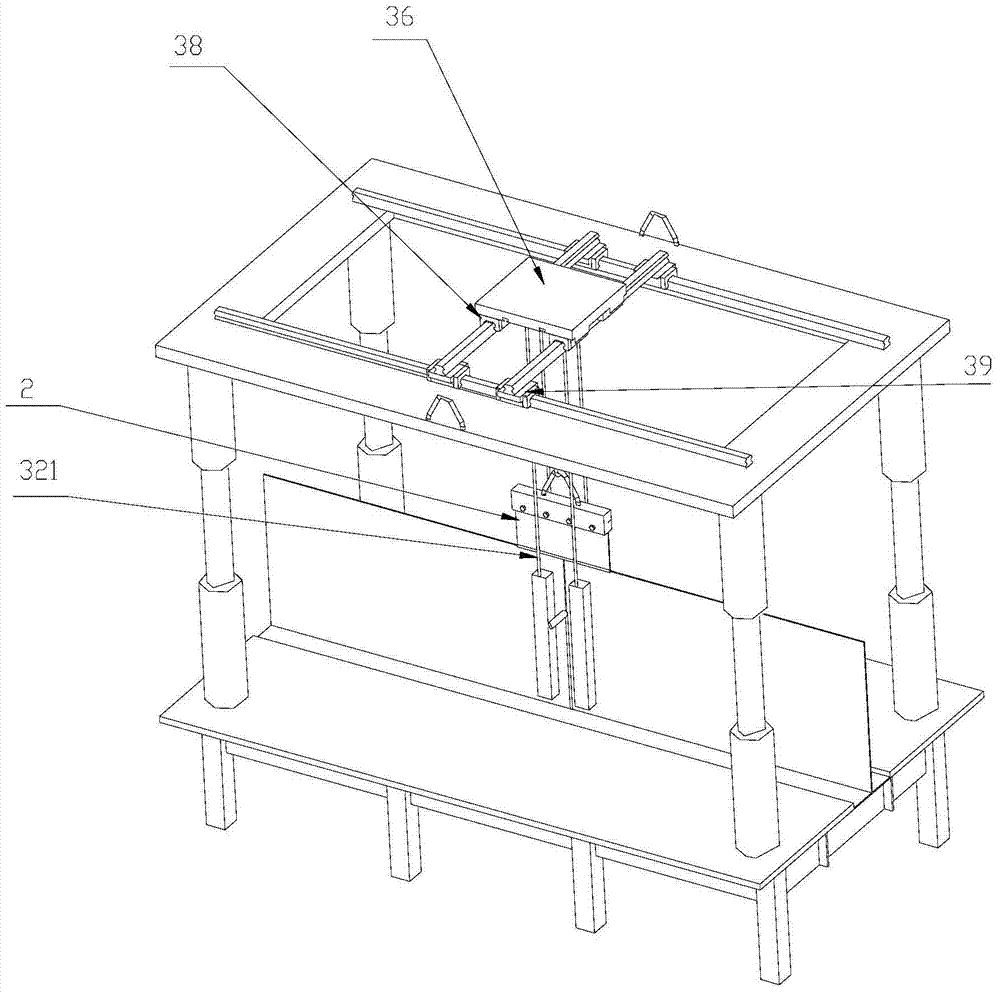

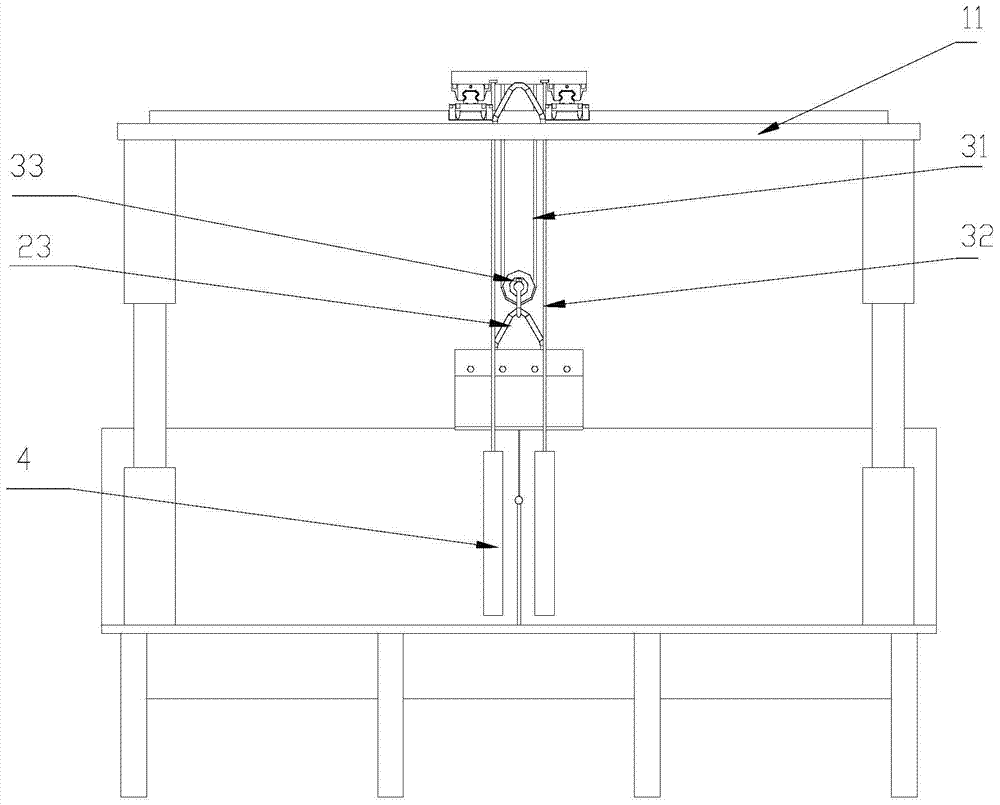

[0036] Such as Figure 1-Figure 4 As shown, the aluminum thin-walled hull vertical weld prestress deformation control device according to the present invention includes a main body structure 1 and a pretension stress applying structure 2, and the main body structure 1 includes a top frame 11, a movable applying The force device 3 and a plurality of uprights 12 , the upper parts of the uprights 12 are fixed on the bottom surface of the top frame 11 , and the movable force applying device 3 is movably arranged in the middle of the top frame 11 .

[0037] Preferably, the column 12 is a hydraulically telescopic column, which can adjust the height of the column 12 and keep the prestress constant during the welding process, so as to facilitate the welding of the vertical wall panels 61 of cabins with different heights. The bottom of the column 12 is provided with a column base 121, so that the deformation control device of the present invention can be placed on the hull bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com