Floatable hatch cover of independent cargo cabin

A hatch cover, floating technology, applied in the direction of ship hatches/hatch, superstructure of trucks, ship parts, etc., can solve the problem of poor strength and rigidity structure, influence, and can not realize the floating of cargo tanks and vehicles Connection and other issues, to achieve the effect of reasonable layout, safe use, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

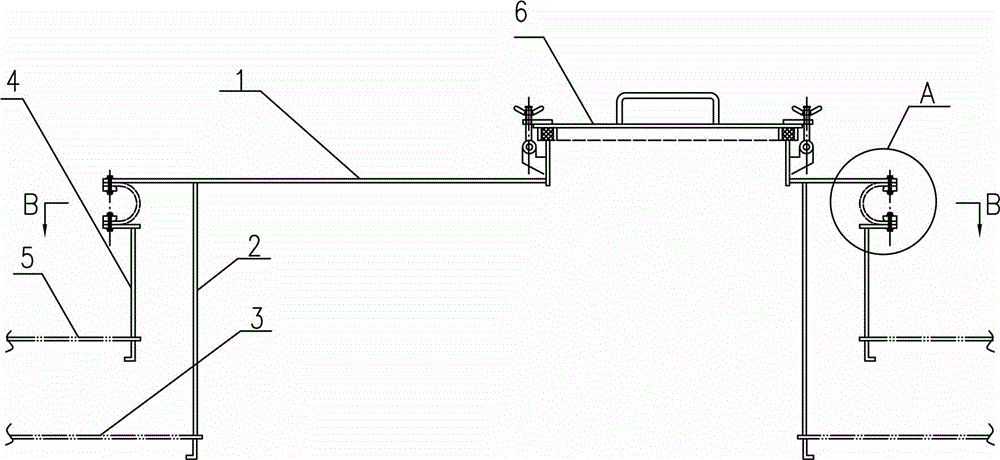

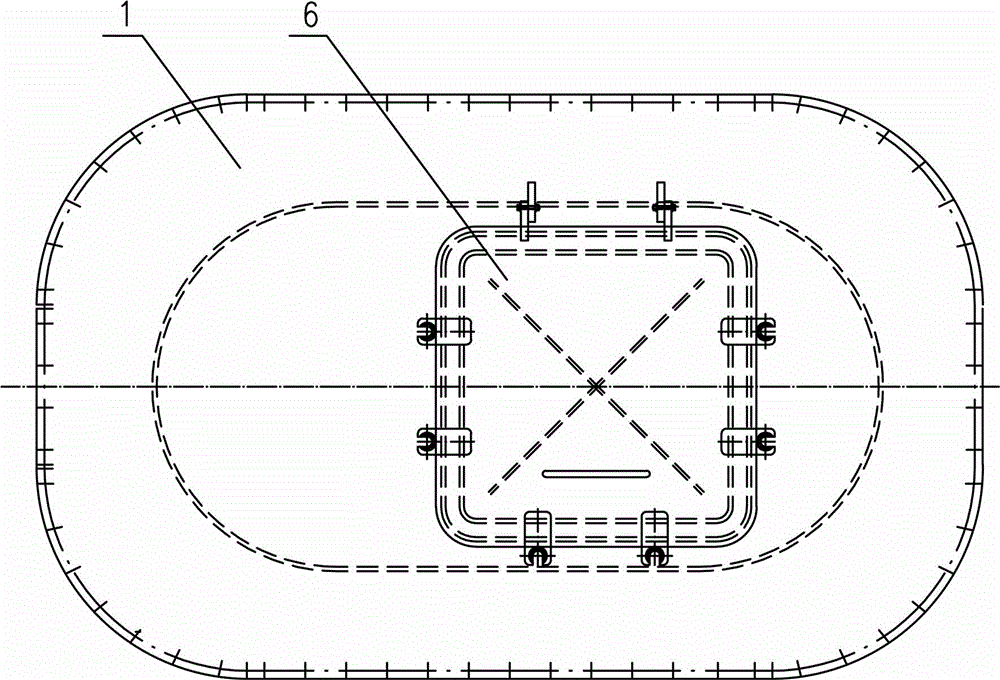

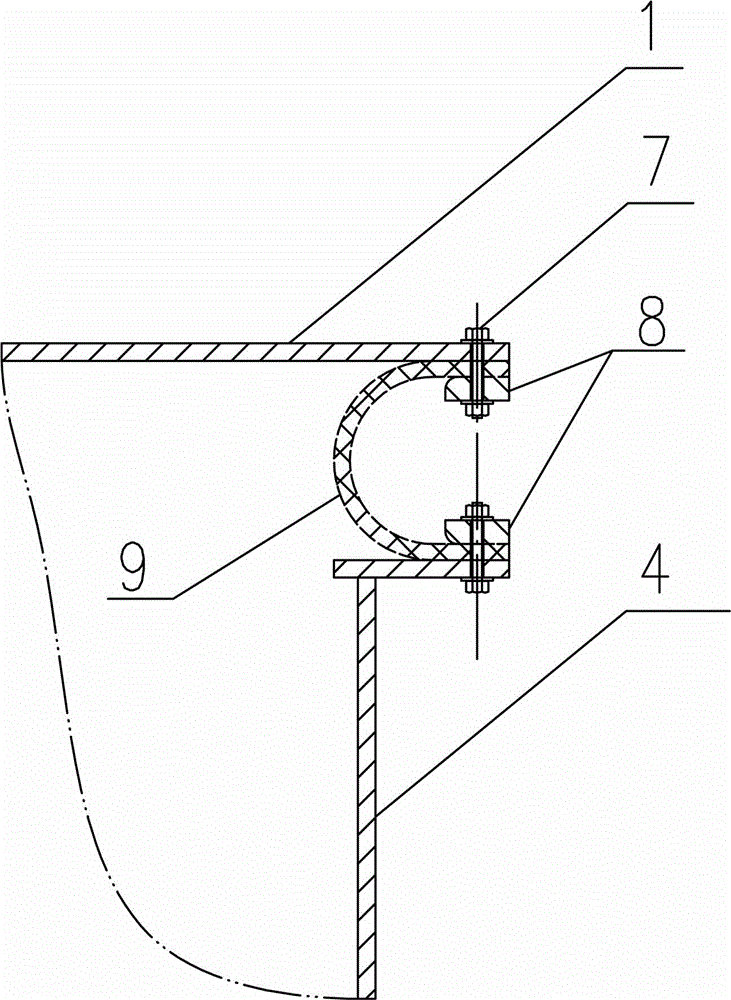

[0018] Such as figure 1 , figure 2 Among them, a floatable independent cargo hold hatch cover, the cargo hold has a double-layer structure of an independent cargo hold panel 3 and a vehicle structural panel 5, there is a gap between the independent cargo hold panel 3 and the vehicle structural panel 5, and the hatch cover includes a cargo hold cover Plate 1, the small hatch cover 6 welded on the cargo compartment cover 1, the cargo compartment cover 1 is welded and connected with the independent cargo compartment panel 3 through the hatch inner coaming 2; 7 and the compression flat steel 8 are compressed and fixed, and the other end is compressed and fixed with the hatch inner coaming 2 connected to the carrier structural panel 5 with the fixing bolt 7 and the compression flat steel 8; the rubber sealing ring 9 is in the cargo hold The gap between the edge of the cover plate 1 and the hatch inner coaming plate 2 is C-shaped.

[0019] In the optimal solution, the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com