Reactive vertical orientation material, liquid crystal display panel and liquid crystal orientation method

A liquid crystal display panel, vertical alignment technology, applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of reducing process yield, affecting panel quality, brush marks, etc., and achieving a simple liquid crystal alignment method and liquid crystal alignment effect. Good, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

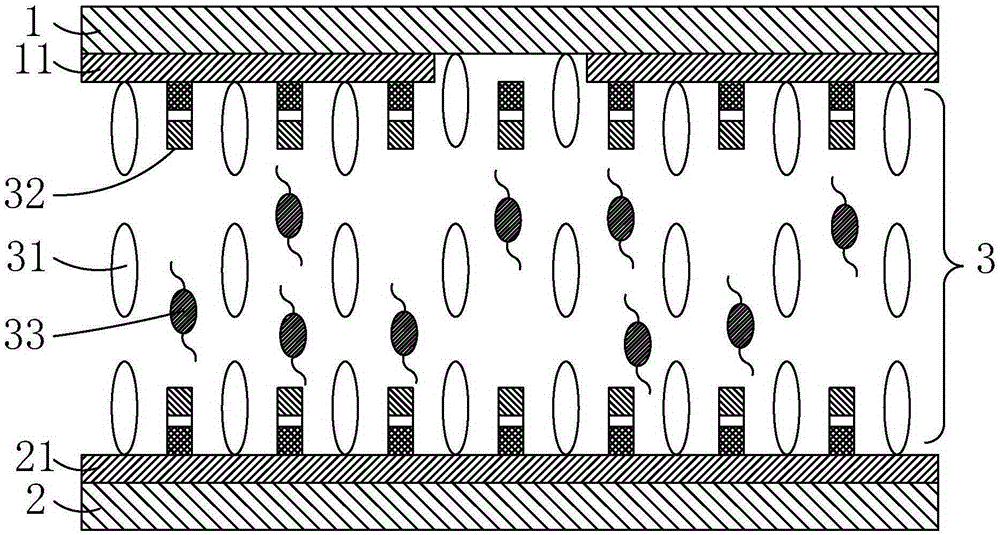

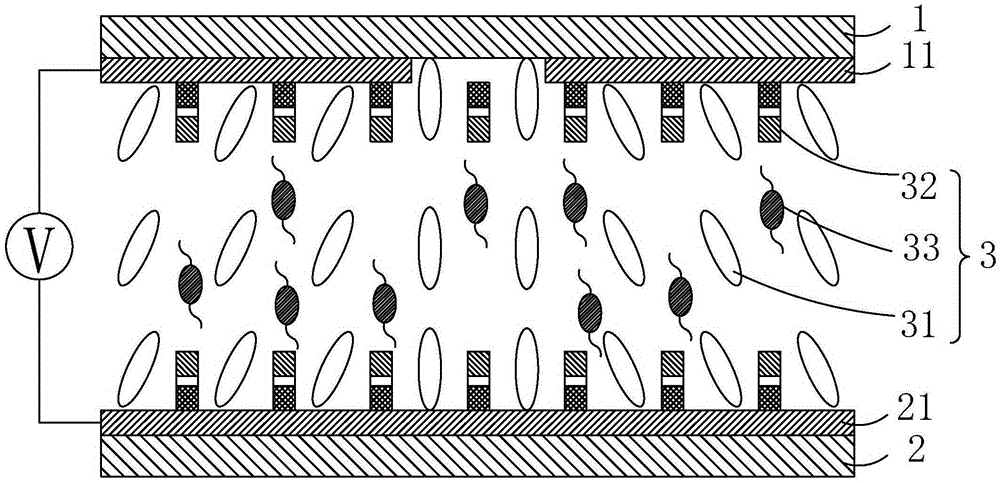

[0042]In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

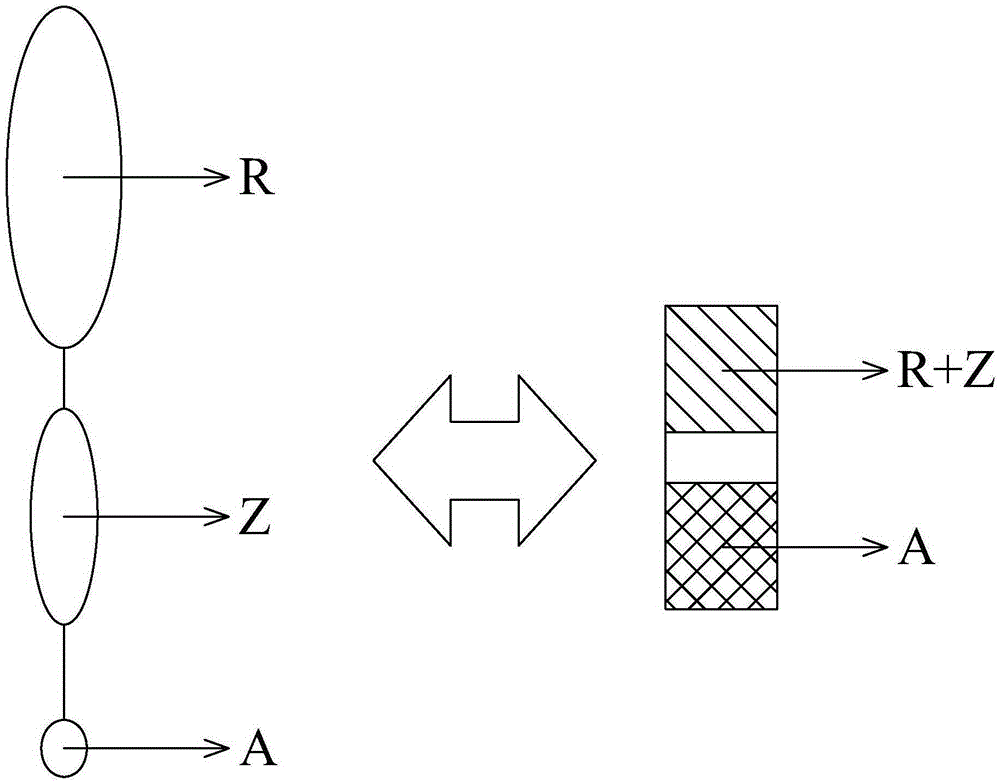

[0043] see figure 1 , the present invention provides a reactive vertical alignment material whose general structural formula is A-Z-R, wherein,

[0044] A means -CH=CH-COOH;

[0045] Z refers to where n≥1;

[0046] R refers to a linear or branched alkyl group with 5 to 20 C atoms, a certain CH in the alkyl group 2 A group substituted by phenyl, cycloalkyl, -CONH-, -COO-, -O-CO-, -S-, -CO- or -CH=CH-, or the alkyl group A group in which a certain H atom is replaced by an F or Cl atom.

[0047] Preferably, the structural formula of the reactive vertical alignment material is:

[0048]

[0049] A reactive vertical alignment material provided by the present invention has a general structural formula of A-Z-R, wherein the function of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com