A Smart Alignment Packing System

A smart, box-packing technology, applied in the field of logistics, can solve problems such as low packing efficiency, and achieve the effects of improving packing efficiency, practical functions, and simple alignment methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

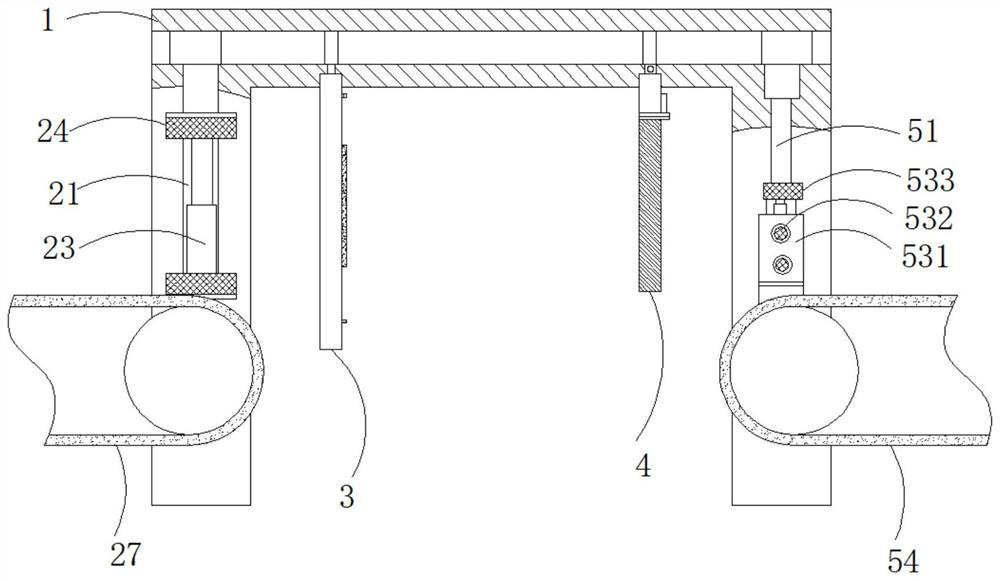

[0045] refer to figure 1 , a kind of intelligent alignment boxing system, including an integral support 1, a packing box manipulator 2 and a cargo manipulator 5 positioned on the integral support 1, the packing box manipulator 2 is located above the discharge end of the packing conveyor belt 27 for transporting the packing box, and the packing box The manipulator 2 is used to grab the packing box, and the goods manipulator 5 is located above the discharge end of the goods conveyor belt 54 for transporting the goods. The goods manipulator 5 is used to grab the goods wrapped by the foam protection block. Figure 7 , between the box manipulator 2 and the goods manipulator 5, a box positioning structure 3 and a goods limiting ring 4 are arranged.

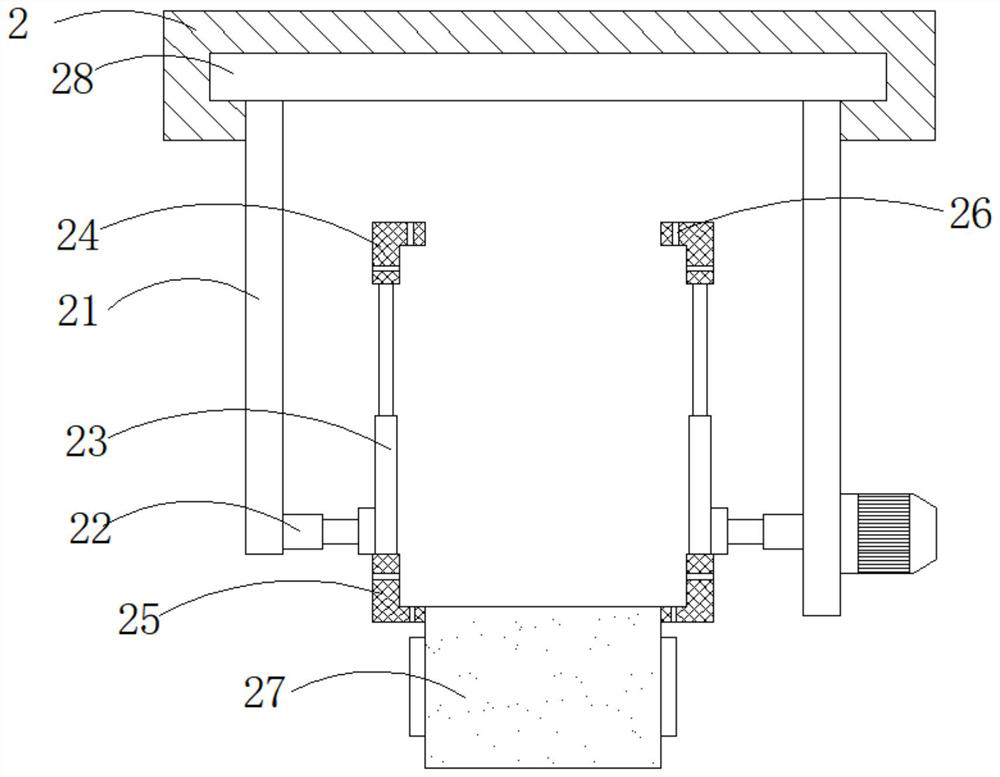

[0046] Specifically, refer to figure 2 , the packing box manipulator 2 includes a load-bearing rod 21, a horizontal clamping cylinder 22, a vertical clamping cylinder 23, an upper gripper 24, a lower gripper 25, a wall thickness detec...

Embodiment 2

[0069] Different from Embodiment 1, the alignment method of the cargo limiting ring (4) in this embodiment and the induction ring in the moving frame (31) is different from Embodiment 1, including the following steps:

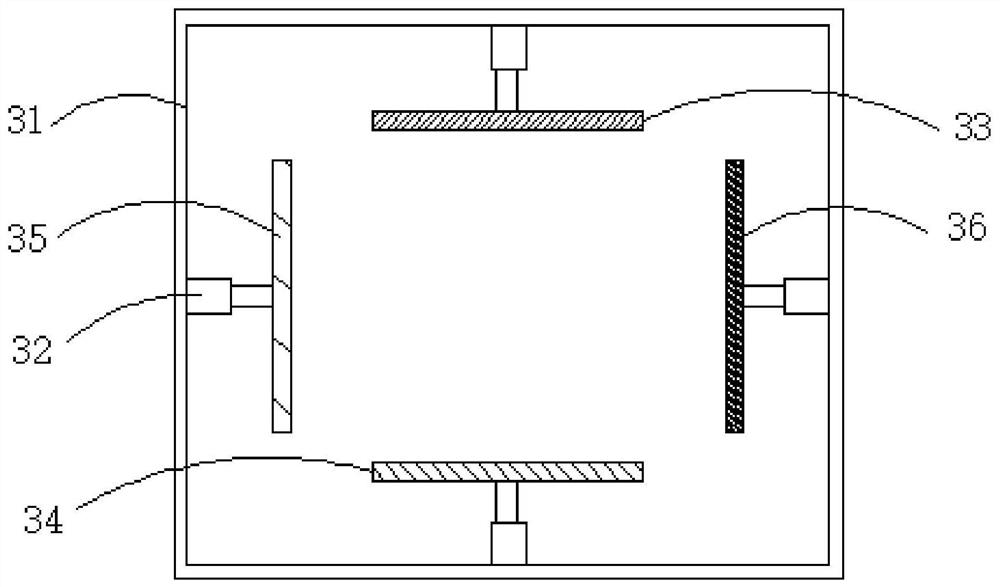

[0070] S1: reference Figure 9 , a plurality of infrared emitters are evenly arranged on upper sensing rod (33), lower sensing rod (34), left sensing rod (35) and right sensing rod (36) in the moving frame (31), and upper sensing rod (33) , lower sensing rod (34), left sensing rod (35) and right sensing rod (36) have different wavelengths of infrared light emitted by the respective infrared emitters, and a photosensitive film is set on the cargo limit ring (4), and the photosensitive film is The photoelectric conversion material is crystalline silicon material (similar to the photosensitive plate of a solar cell), and cooperates with the photoelectric conversion module to change the light intensity into the current intensity. The width of the two infrared emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com