Lubrication-free step chain

A step chain, lubrication-free technology, applied in the direction of transmission chains, belts/chains/gears, transmission parts, etc., can solve the problems of large loss of lubricating oil, easy pollution of the environment, etc., to reduce wear and tear, reduce environmental pollution, structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0024] The technical scheme of concrete implementation of the present invention is:

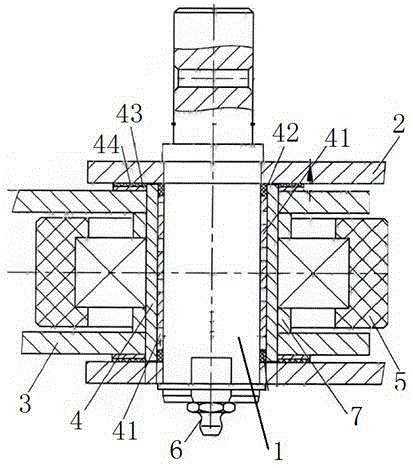

[0025] Such as figure 1 As shown, a non-lubricating step chain, including the inner chain link and the outer chain link;

[0026] The outer chain link includes a pair of outer chain plates 2 connected with the pin shaft 1;

[0027] The inner chain link includes a pair of inner chain plates 3 connected with the sleeve 4;

[0028] The sleeve 4 is sheathed on the outer periphery of the pin shaft 1 and is located between the pair of outer link plates 2;

[0029] The outer circumference of the sleeve 4 is also sleeved with a roller 5, and the roller 5 is located between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com