A Test System for Simulating Steam Consumption of Secondary Circuit Turbine

A test system and steam turbine technology, which is applied in the field of the test system for simulating the steam consumption of the secondary circuit steam turbine, can solve the problems of high cost and complex structure of the steam turbine, and achieve the effect of solving the difficult problem of the secondary circuit simulation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

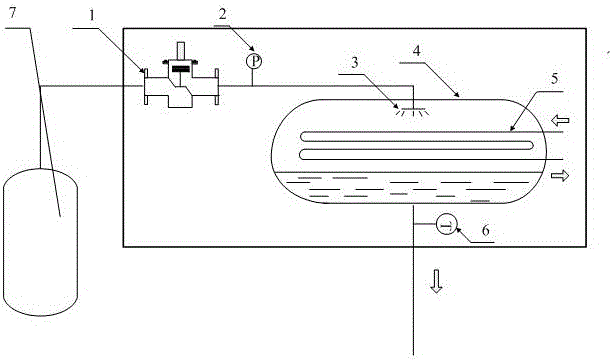

[0020] A test system for simulating the steam consumption of a secondary circuit steam turbine, including a steam generating device 7 connected in sequence, a steam pressure reducing valve 1, a spray head 3, and a condenser 4, the spray head 3 is arranged inside the condenser 4, and the steam is decompressed A pressure measuring device 2 is provided on the connecting pipe between the valve 1 and the spray head 3 .

[0021] The main equipment in the test system is steam pressure reducing valve and condenser. In a real reactor, steam is generated from the secondary side of the steam generator and enters the turbine through the main steam line. In the test system provided by the present invention, after the steam flows out from the secondary side of the steam generator, it enters the main steam pipeline, and a steam pressure reducing valve is set on the main steam pipeline, and the steam is throttled and depressurized by the pressure reducing valve to become low-pressure steam ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com