Automatic regulating apparatus of hot disc processing closed chamber

An automatic adjustment device, closed cavity technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as personal injury, exhaust gas leakage, personal and company economic losses, and achieve a good contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

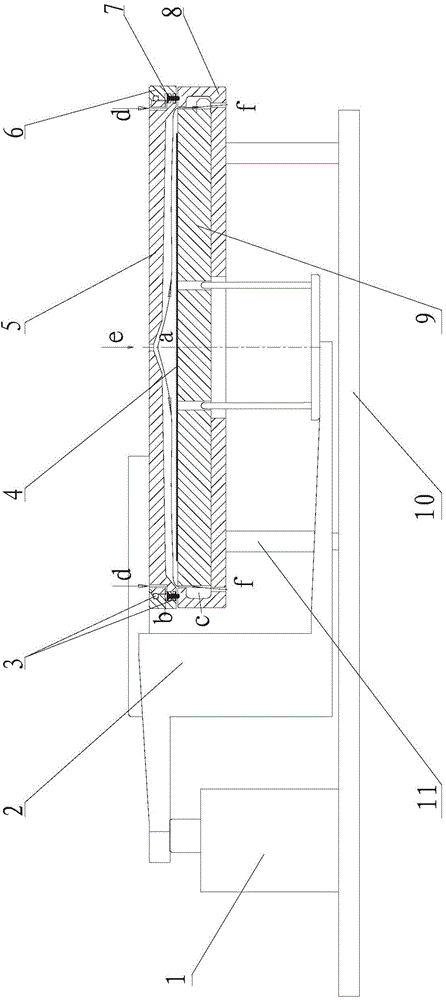

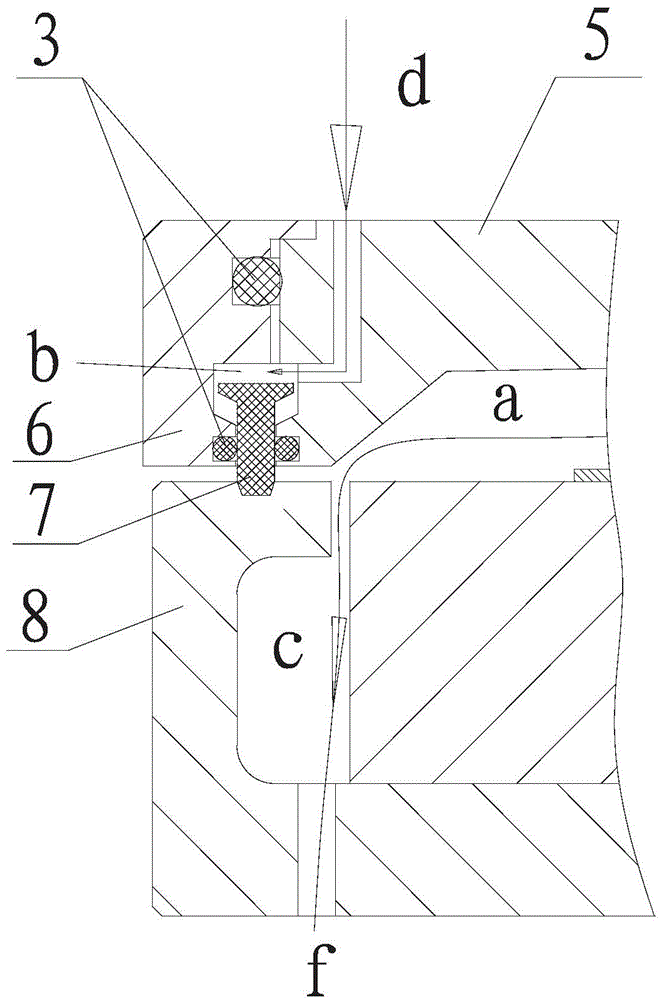

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a driving mechanism 1, a disc cover lifting mechanism 2, a disc cover, a sealing ring 7, a lower sealing body 8, a disc body 9 and a bottom plate 10, wherein the driving mechanism and the lower sealing body 8 are installed on the bottom plate 10 through a pillar 11 Above, the disc body 9 is arranged in the lower sealing body 8, and the disc cover is arranged on the upper end of the sealing body 8. The connected first process chamber a and the second process chamber c. The outer edge of the lower end surface of the disc cover is provided with a self-adjusting cavity b along the circumferential direction, and the outer edge of the upper end of the lower sealing body 8 is provided with a groove along the circumferential direction, and one end of the sealing ring 7 is accommodated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com