a fishing reel

A technology of fishing reels and reels, which is applied in fishing reels, fishing, applications, etc., can solve problems such as increased friction, high manufacturing costs, and casting failures, and achieves increased dynamic fishing power and easy use Low technical requirements and the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

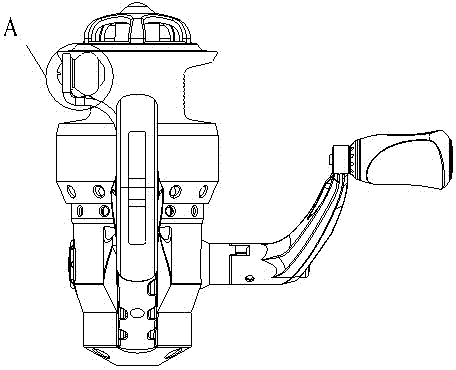

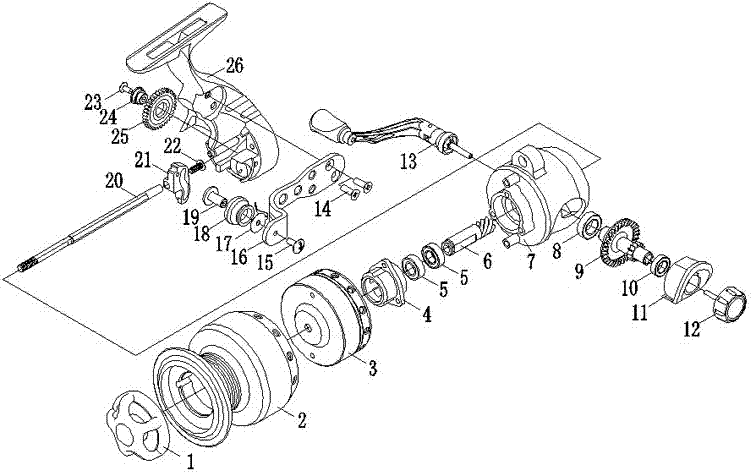

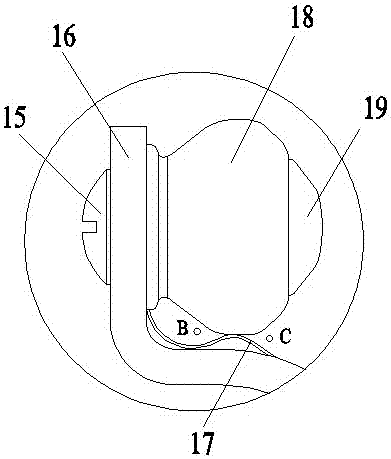

[0017] combine figure 1 and figure 2 , the fishing reel of the present invention comprises main body 26, main body head 7 and main body headgear 3, and described main body head 7 is provided with rocker arm 13, and described rocker arm 13 is connected with main body head 7 by first bearing 8. The toothed plate 9 is connected, the second bearing 10 is provided between the toothed plate 9 and the toothed plate cover 11, the rocker arm cover 12 is fastened on the toothed plate cover 11; the transmission gear 25 passes through the transmission gear screw 23 and the gear sleeve 24 Fixed in the main body 26, the transmission gear 25 meshes with the toothed disc 9; the main body head 7 and the main body headgear 3 are provided with a gear bar 6, and the gear bar 6 is provided with an inner hole, and the gear bar 6 One side close to the main body head 7 is provided with threads to mesh with the gear plate 9, the gear rod 6 is provided with a single-row bearing 4, and the third bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com