End component, hollow fiber membrane module and membrane filter unit

A fiber membrane and hollow technology, applied in the field of water treatment, can solve problems such as sedimentation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The head part is a housing with a collecting chamber. The end part divides the housing into an area with a through-channel and an area without a through-channel, wherein the through-channel completely penetrates the housing and becomes a drainage channel for the hollow fiber membrane tow row 1 . The casing surrounds the liquid collection chamber, which is a cavity. The liquid collecting chamber has multiple openings called the liquid collecting chamber receiving port, and the liquid collecting chamber receiving port is used to receive the connection of the liquid outlet of the hollow fiber membrane tow row 1, collect the output filtrate, and collect it into the liquid collecting chamber cavity. Both the liquid collecting chamber and the receiving port of the liquid collecting chamber are arranged on the area of the housing without a through passage. Therefore, the through-channel and the liquid collection chamber are integrated in a housing such as the terminal part...

Embodiment 2

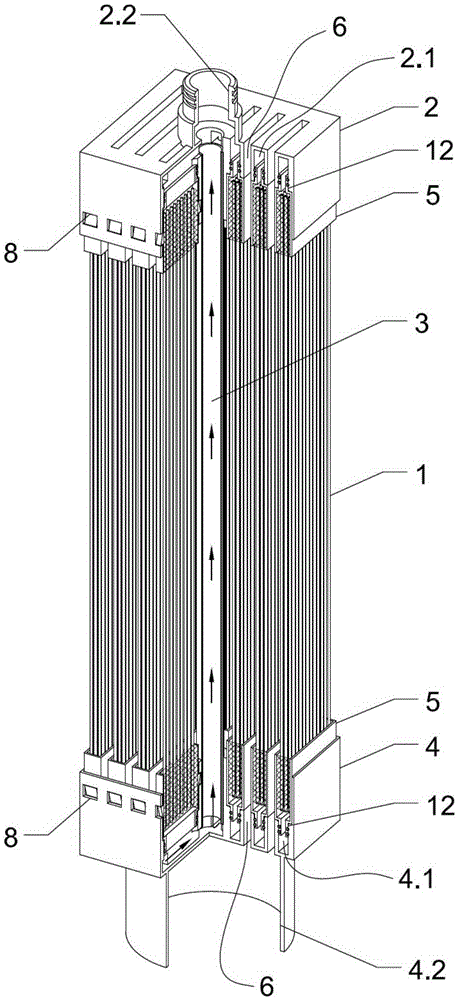

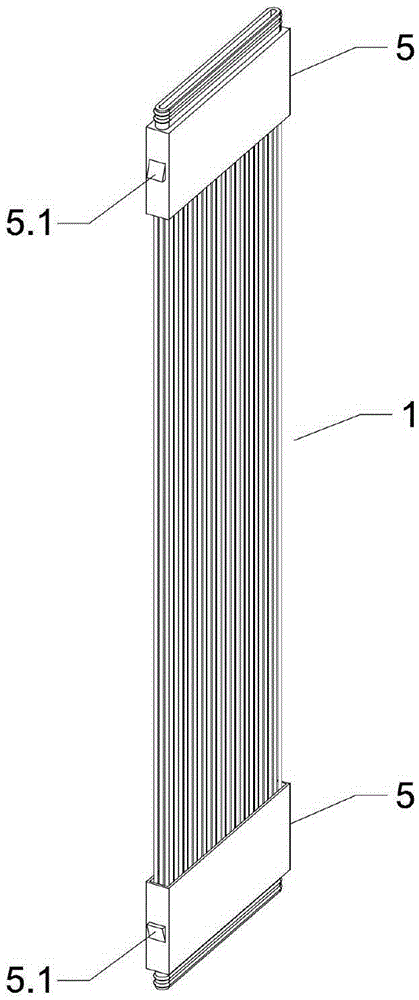

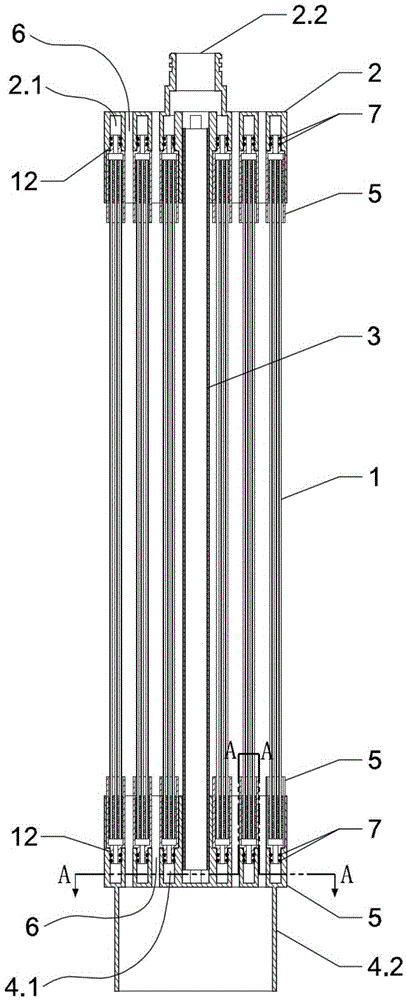

[0086] Such as figure 1 , figure 2 , image 3 As shown, the upper and lower ends of multiple hollow fiber membranes are cast and fixed in the filtrate collection plug 5 with resin and other materials to form a hollow fiber membrane tow row 1, and the hollow fiber membrane end faces in the filtrate collection plug 5 at the upper and lower ends are used for openings. After the filtered liquid flows out, a plurality of hollow fiber membrane tow rows 1 are arranged in parallel with each other between the upper end 2 and the lower end 4, and the filtrate collecting plugs 5 at the upper and lower ends of the hollow fiber membrane tow row 1 are arranged on both sides There are raised buckles 5.1, the two side walls of the corresponding positions of the upper end 2 and the lower end 4 are provided with buckle matching ports 8, and the raised buckles on both sides of the filtrate collection plug 5 at the upper and lower ends of the hollow fiber membrane tow row 1 The bit 5.1 is asse...

Embodiment 3

[0093] Such as Figure 8 As shown, a plurality of hollow fiber membrane module arrays form a membrane filtration unit, an aeration distribution pipe 101 and an aeration head 102 are arranged at the bottom of the hollow fiber membrane module, and a filtrate collection branch pipe 103 and a filtrate collection branch pipe 103 are arranged on the top. Manager 104. Among them such as Figure 9 , the aeration head 102 is located inside the fluid confinement cover 4.2 of the lower end 4 of the hollow fiber membrane module, and the aeration head 102 also plays a role of limiting and fixing the hollow fiber membrane module. The aeration distribution pipe 101 introduces gas from the gas source, releases it through the aeration head 102, and enters each hollow fiber membrane module.

[0094] Such as Figure 10 , the aerator head 102 is provided with an airflow buffer chamber 102.1, four airflow guide pipes 102.2 are radially distributed with the airflow buffer chamber 102.1 as the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com