Driving assembly for hot water cleaning machine

A technology of hot water cleaning and driving components, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of many cleaning parts, complex structural design, high production costs, etc., and achieve production cost reduction , flexible structure design, and the effect of automatic cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

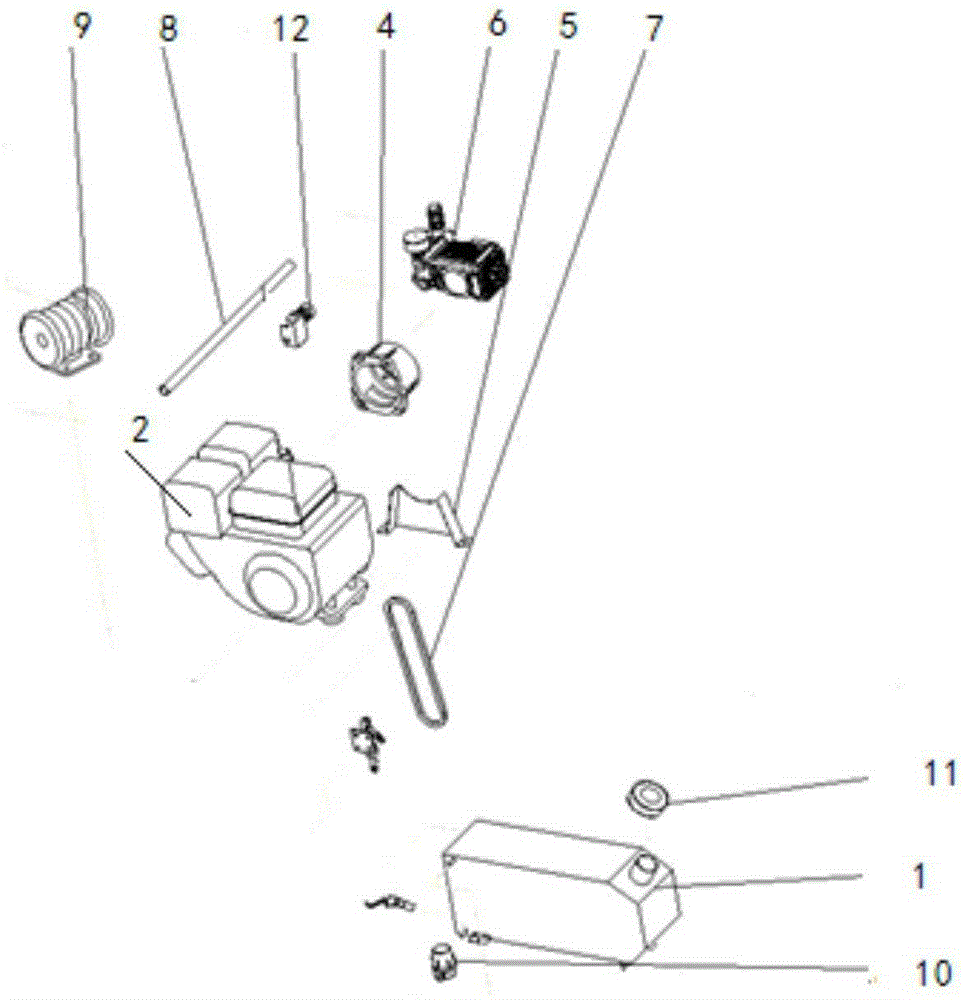

[0010] Referring to the accompanying drawings, the driving assembly for the hot water washing machine includes a fuel tank 1 and a gasoline engine 2. The two ends of the fuel tank 1 are connected to the gasoline engine 2 through the fuel tank oil inlet pipe 3 and the fuel tank outlet pipe 10. The gasoline engine flange 4 and the transmission box are installed on the gasoline engine 2. 5. A water pump 6 is connected to the flange 4 of the gasoline engine, and the transmission box 5 drives the traveling wheels through the belt 7. The water pump 6 is connected to the water pump outlet pipe 8, and the water pump outlet pipe 8 is wound on the hose reel 9; There is a pressure switch 12. A filter 10 is provided in the filling port of the fuel tank 1, and a fuel tank cap 11 is installed on the filling port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com