Washing machine having honeycomb and flexible friction washing devices

A kind of washing machine, flexible technology, applied in the field of household electric washing machines, can solve the problems such as material selection and structural design are not deep enough, mildew and cleaning problems are difficult to solve, and the washing effect is not obvious, so as to achieve high structural design efficiency and flexible structural design The effect of changing and shortening the washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

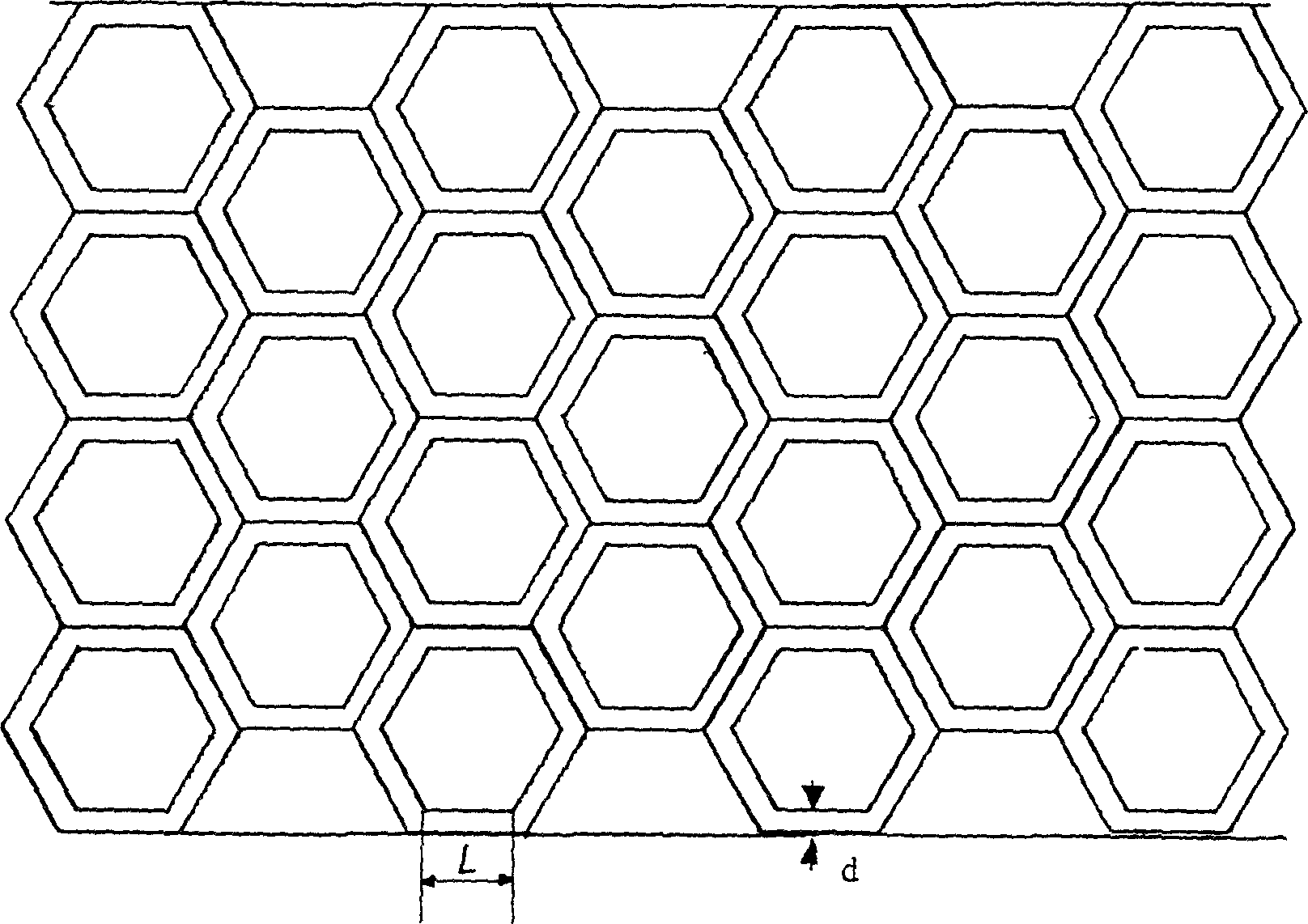

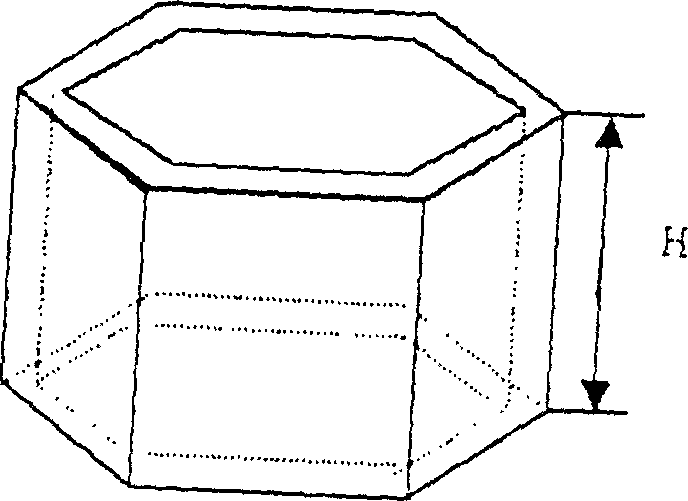

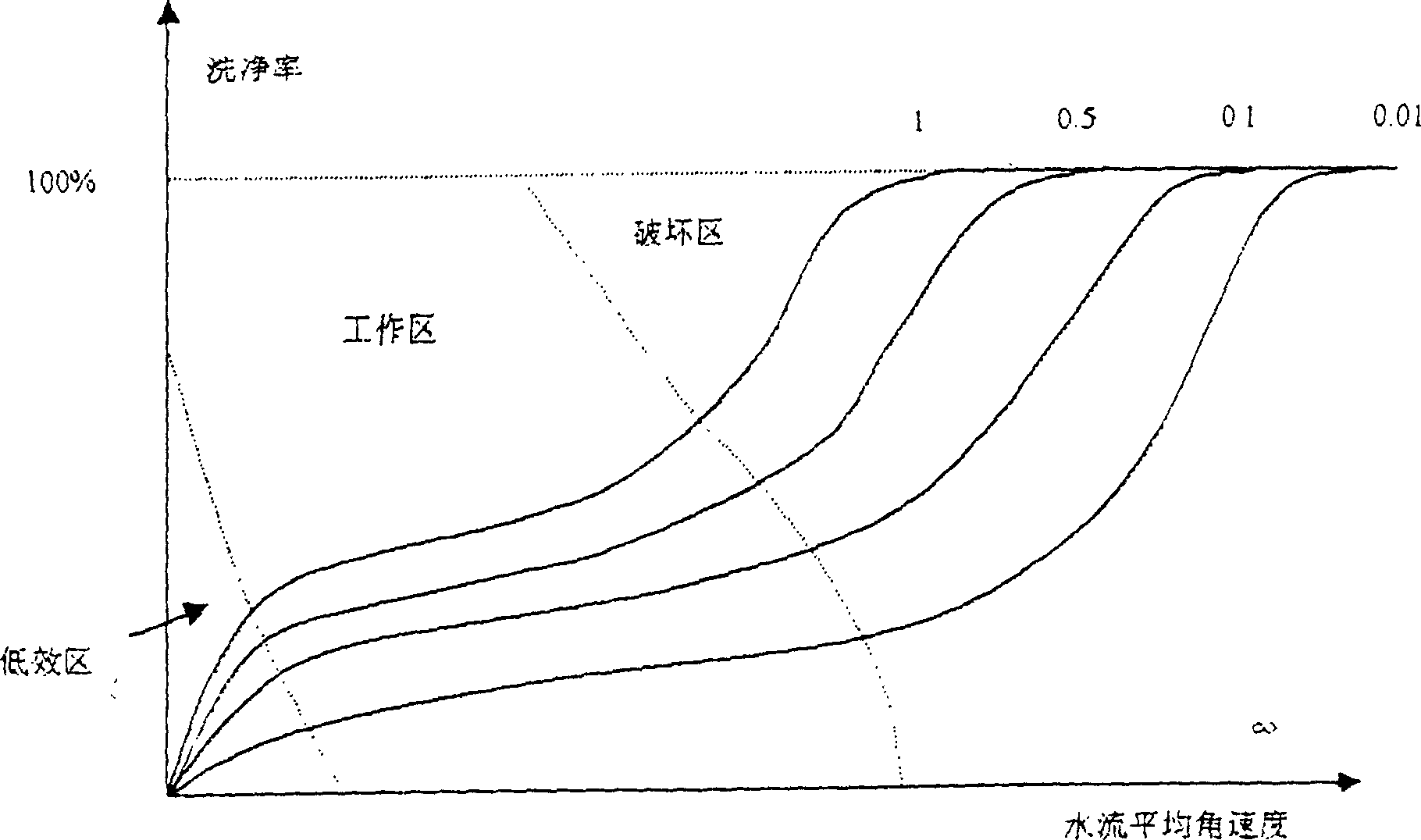

[0052] This embodiment is based on the pulsator washing machine, and both the washing inner cylinder wall and the pulsator are made of polyurethane material. Honeycomb holes are evenly distributed on the inner cylinder wall and the impeller. The honeycomb hole is a regular hexagonal hole, the side length L of the regular hexagon is 3mm, the wall thickness d of the regular hexagon is 0.3mm, and the depth H of the honeycomb hole is 2.5mm, see figure 1 , figure 2 . There are oblique ribs on the wall of the cylinder, and the honeycomb holes on it are regular hexagonal holes. and the cylinder wall; the protruding height of the oblique ribs is 15 mm, the width is 20 mm, and the angle with the cylinder mouth is 30 degrees. Both the inner cylinder wall and the pulsator adopt long-term reciprocating, and the six-stage layered water flow washing program rotates. The direction of rotation of the pulsator is opposite to that of the inner cylinder. It is divided into start water flow...

Embodiment 2

[0056] In this embodiment, fiber grids are evenly distributed on the inner cylinder wall of the washing machine, the grid density is 400-1600 per square decimeter, and the fiber material is vinyl chloride acrylonitrile copolymer. The inner cylinder wall is provided with permeable holes, lint collectors and oblique ribs. Long-cycle reciprocating, six-stage layered water washing program: divided into start water flow, working time is 1.2 seconds, stop time is 0.9 seconds; main washing water flow, working time is 3 seconds, stop time is 1.8 seconds; transition water flow, The working time is 0.9 seconds, and the stop time is 1.2 seconds; then reverse rotation, the same is to start the water flow, the working time is 1.2 seconds, and the stop time is 0.9 seconds; the main washing water flow, the working time is 3 seconds, and the stop time is 1.8 seconds; Transition water flow, the working time is 0.9 seconds, and the stopping time is 1.2 seconds.

Embodiment 3

[0058] This embodiment is based on the drum washing machine, the washing inner cylinder wall is made of polyurethane material, and the outer lining is stainless steel cylinder. The cylinder wall is 5mm thick. Honeycomb holes are evenly distributed on the inner cylinder wall. The honeycomb holes are regular hexagonal holes, the side length L of the regular hexagon is 2.5mm, the wall thickness d is 0.3mm, the honeycomb hole depth H is 5mm, and it runs through the cylinder wall. There are only oblique ribs on the cylinder wall, and the honeycomb holes on it are regular hexagonal holes, the range of the side length L of the regular hexagon is 2 mm, the range of the thickness d of the honeycomb hole wall is 0.3 mm, and the range of the depth H of the honeycomb holes is 20 mm, through the oblique ribs and the wall; the protruding height of the oblique ribs is 15 mm, the width is 20 mm, and the angle with the mouth of the cylinder is 30 degrees. The above oblique ribs. See figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com