Engine air filter element cleaner

An engine air filter and cleaner technology, which is applied in the field of cleaners, can solve the problems of dust being easily inhaled by the human body, secondary pollution of the working environment, and affecting health, so as to achieve ingenious design of the overall structure, reduce labor intensity, and ensure physical health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

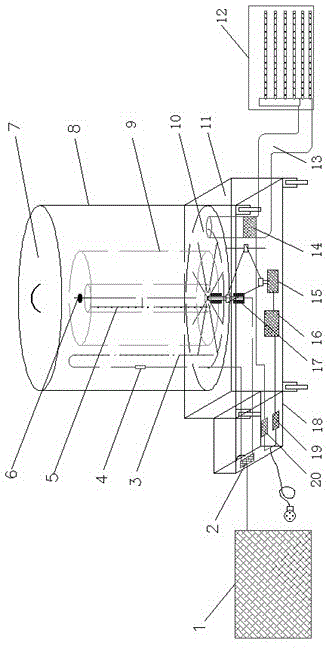

[0017] Embodiment 1: see figure 1 , an engine air filter element cleaner, the cleaner includes a body 8, an upper cover 7 is arranged above the body 8, a frame 11 is arranged below the body 8, and one side of the frame 11 A control box 18 is provided, and the control box 18 is installed on the frame 11 at the rear of the body 8. A mesh bearing plate 10 is arranged inside the body 8, and an air filter element 9 is arranged on the mesh carrier plate 10. , the frame 11 is also provided with a driving device and a transmission device 15, the inner nozzle pipe 5 and the outer nozzle pipe 3 of compressed air are arranged in the body 8 of the filter element cleaner, and the outside of the body 8 is provided with an exhaust system.

[0018] The driving device includes a main motor 16 and a main motor switch 19 for controlling the main motor 16 , and the main motor 16 and the main motor switch 19 are arranged in a control box 18 . The exhaust system includes an exhaust fan 14 , an ex...

Embodiment 2

[0019] Example 2: see figure 1 , as an improvement of the present invention, the outer nozzle 3 is set in an inverted "U" shape, and the inner nozzle 5 is set in an "H" shape. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0020] Embodiment 3: see figure 1 , as an improvement of the present invention, the transmission device 15 is composed of a two-stage reduction motor, a first-stage reduction device and a second-stage reduction device, wherein the first-stage reduction device is a worm gear reducer, and its reduction ratio is 10 :1; The second stage reduction device is driven by belt and pulley. The size of the pulley is customized according to the speed requirement to achieve the deceleration effect. The reduction ratio is 4.8:1. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com