Run-out table

A technology of output roller table and transparent cover, which is applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve problems such as grease emulsification, achieve the effect of preventing grease emulsification, preventing production interruption, and stabilizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

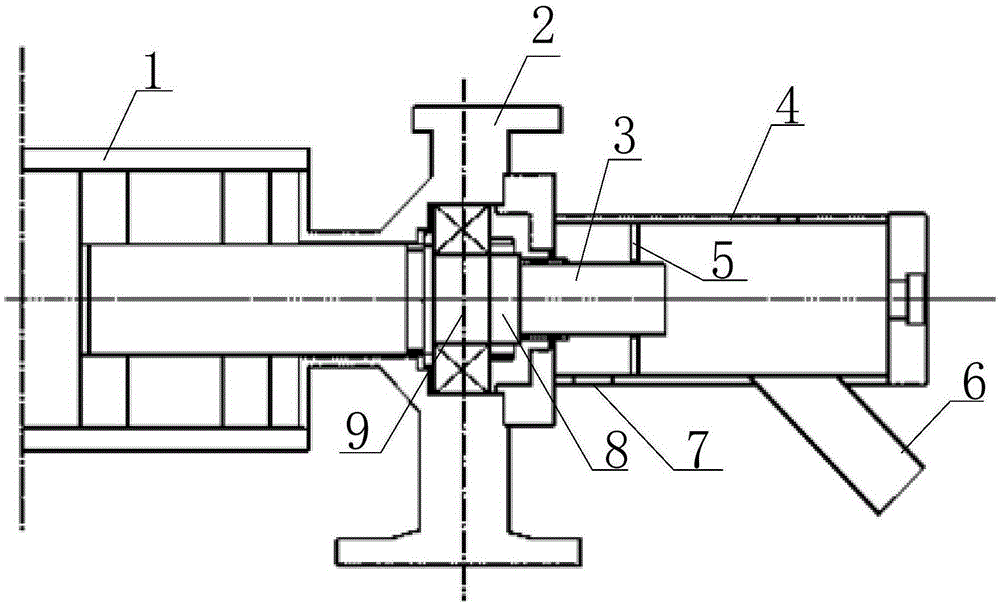

[0015] The embodiment of the present invention provides an output roller table, which solves the technical problem in the prior art that the return water splashed at the front end of the return shaft of the roller table easily enters the bearing end, thereby emulsifying the lubricating grease inside the bearing and preventing the return water from entering the bearing. end, reducing the failure rate of the output roller table.

[0016] see figure 1 , The embodiment of the present invention provides an output roller table, including: a shaft body 1, a bearing housing 2, a bearing 9, a bearing lock nut 8, a return shaft 3, a transparent cover 4, a water retaining plate 5 and a drain pipe 6.

[0017] see figure 1 , the shaft body 1 is fixedly connected to the rear end of the bearing seat 2, the transparent cover 4 is connected to the front end of the bearing seat 2, and the horizontal centerlines of the shaft body 1, the bearing seat 2 and the transparent cover 4 are arranged on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap