A method and device for automatic riveting of brake pads

A brake pad and riveting technology is applied in the field of automatic control of brake pad riveting, which can solve the problems of a large proportion of manual operations and a low level of automation, and achieve the effects of good consistency, high level of automation, and a reduction in the proportion of manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below in conjunction with specific embodiments.

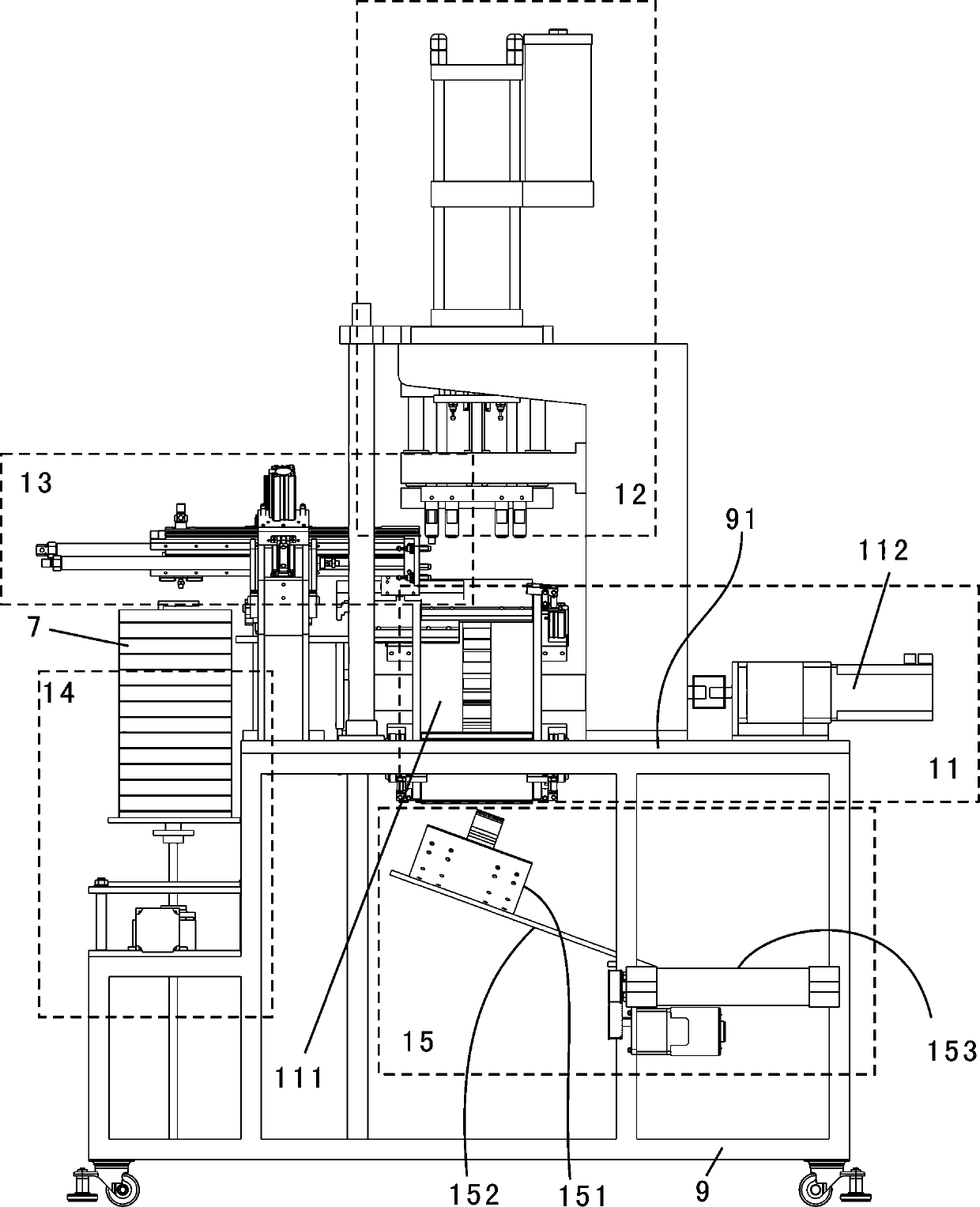

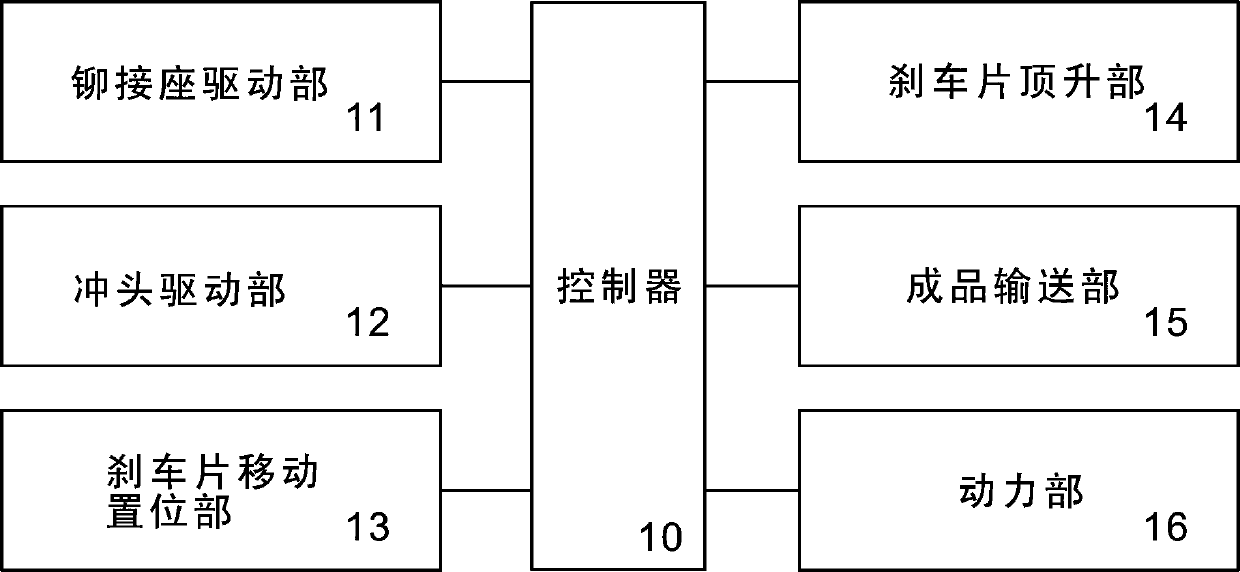

[0040] Such as Figure 1 ~ Figure 3 As shown, implement a method for automatic riveting of brake pads, comprising the steps:

[0041] S1, at first, set a riveting seat driving part 11, it is installed on the platform 91 of support 9; Said riveting seat driving part 11 has a cylindrical riveting seat 111 driven by the riveting seat drive motor 112;

[0042] S2. Then, above the cylindrical riveting seat 111, a punch driving part 12 is arranged, and the punch driving part 12 has a stamping cylinder, and the stamping cylinder connects the punch to move downward;

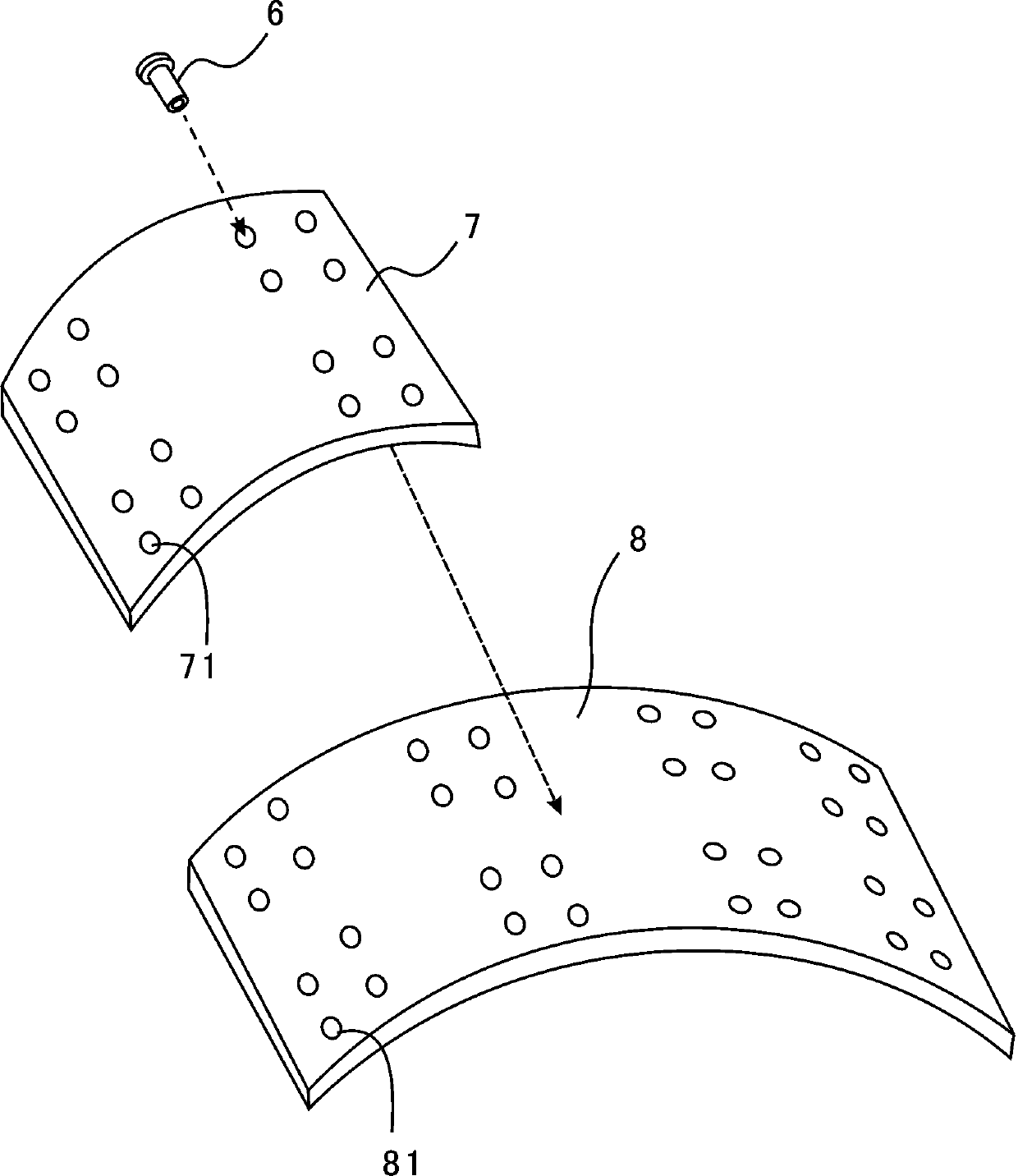

[0043] S3. Then, on one side of the support 9, a brake pad lifting portion 14 is set, and the brake pad lifting portion 14 lifts the brake pad 7 to be processed to a position to be sent higher than the cylindrical riveting seat 111;

[0044] S4. Then, on the side above the cylindrical riveting seat 111, a brake pad moving a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com